Product Description

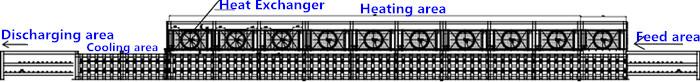

1. The mesh type dryer is composed of several separate unit sections, each of which includes a circulating fan, a heating device, a separate or public fresh air pumping system and a exhaust system.

2. Its working principle is that the wet materials are evenly distributed to the conveyor belt from the feeding device at the feed end, the hot air is sent through the distribution board to the lower part of the conveyor belt to blow vertically, or to the upper part of the conveyor belt to blow down vertically, and the hot air passes through the material layer. Vaporize the moisture in the material, remove part of the wet steam from the box, and recycle the other part.

3 The mesh type drier is driven by variable speed motor, which can be adjusted according to the properties of material, output, temperature and humidity to ensure the quality of the product.

4. It is composed of four parts, which are divided into Feeding area,Heating area,Cooling area and Discharging area.

5. It is mainly used for drying core plate, partial surface and bottom plate.

6. It has high efficiency, low energy consumption, and better meets the production process of the product.

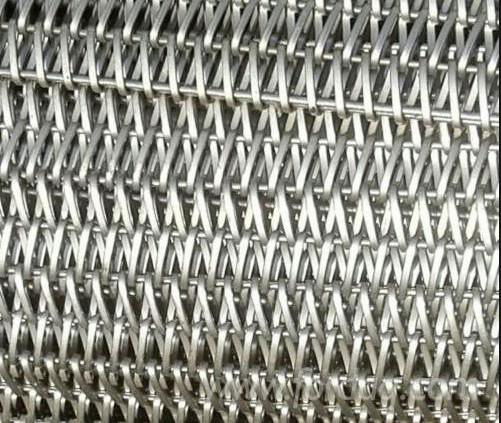

7. This machine adopts two or four layers rollers to transport the veneer (the device for conveying the veneer is different according to the thickness of the plate)

8. The heat transfer oil is the heating medium (the heating source can be changed according to the requirements of different customers and ΔThe above quote does not include heat source configuration)

9. We can design the veneer dryer as customer`s project requirement.

10. It is suitable for the production process of cutting first and then drying, especially for the drying of thick veneers.

11. his machine adopts a number of high-tech and advanced electronic control technology, so it has the characteristics of high efficiency, energy saving and good dry quality.

12. it is designed according to the unit structure principle. The standard of the machine is 11 sections. The two-meter standard is a drying section, it can be arbitrarily selected by the customers according to the output. (5~15 sections)