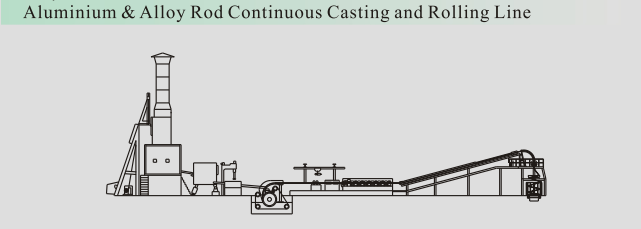

1.产品名称及型号(Machine Name & Type)

UL+Z-1500+255/14型铝,铝合金杆连铸连轧生产线

UL+Z-1500+255/14 Aluminium & Alloy Rod Continuous Casting and Rolling Line

2.产品用途(Machine Application)

* 生产线主要用于生产直径为9.5mm的高强度铝合金导电杆,也可生产生产普通导电铝杆,具有与国际同类产品相当的水平。

Specially for producing aluminium alloys rod of diameter 9.5mm for electrical wire, such as Al-Mg-Si

electrical conductor of high intensity. And also it can produce electrical aluminium rod. The line

is competitive with the relative international products level.

3.产品特点(Machine Characteristic)

* 可采用倾动式保温炉,便于铝合金的制备、均匀精炼和浇铸流量的控制。

Tiltable type holding furnace designed to provide easy access for final preparation

of individual alloys..

* 在线除气和过滤工艺提供优质的铝液供浇铸所用。

In-line filter & degassing device to provide maximum quality liquid metal to the casting machine

* 拥有专利技术的连续浇铸机。结晶轮为“H”型,四面冷却保证铸锭结晶致密且均匀。

内冷环 、外冷环和侧冷环可方便地从结晶轮中转出,便于冷却水调节和维护;所有喷嘴,内、外、侧冷环均为不锈钢,分别

设有压力显示、流量调节阀组。钢带张紧为气动张紧,保证张紧力可调。

The continuous casting machine has been awarded the patent right.

Crystallizing wheel is in type of "H", on every side of which there is an adjustable nozzle spraying

water to ensure the crystal of the cast bar close and equal.It is easy for inner cooling, outer cooling

and side cooling ring to rotate out from the crystallizing wheel to adjust and maintain the cooling water.

Stainless steel is adopted as material for nozzles, inner or outer or side cooling rings, each of which

is equipped with pressure indicator and flowrate adjusting valve. The pneumatic system is used for

tightening steel belt, easy for adjusting..

* 感应加热器保证铸坯进轧的工艺温度要求,具有提温功能,自动加热、调节。

Induction heater meets the temperature requirement of the cast bar for rolling process.

With the function of temperature rising, it can do heating and adjusting automatically.

* 连轧机具有主动喂料和堆杆停车功能。独特的二辊和三辊结合的轧制方式,使得轧制的杆材具有优良的机械性能。

轧机乳液和油路自成封闭系统,具有冷却、过滤和总管压力指示功能。

The continuous rolling machine has a function of automatic feeding and rods stacking stop.

With an unique rolling method combining 2-high rolling stand with 3-high rolling stand, the aluminium

rod is provided with a good mechanic performance. The rolling emulsion and oil pipe form a closed

system with the cooler, filter and indicator for pressure of the main pipe.

* 生产线具有连续淬火、快速冷却功能。淬冷用的水系统自成封闭系统,具有冷却、过滤、总管压力和温度指示功能。

The production line is provided with the function of continuous quenching and fast cooling.

The water pipeline makes a closed system by themselves with cooler, filter and indicator for main pipe

presssure and temperature.

* 收线导管出口处装有吹水装置,以清除铝合金杆表面水份。同时安装有主动牵引装置,保证铝杆的顺利导出。圆弧导向管

采用滚轮导向结构,减少铝合金杆表面擦伤。

To clean off the moisture on the surface of the aluminium rod, a blower is fixed at the end of the guiding

pipe. At the same time, an pinch-roller is installed to ensure a smooth delivery of the rod. The arc guiding

pipe is in a trolley-guiding construction to reduce the scratch upon the wirerods surface.

* 绕杆方式为离心甩头式,一方面使铝合金杆在进入收线框前给予预变形;另一方面使其在轧制过程中若发生断杆,

杆尾能自动到收线框内。

The rod is coiled by means of centrifugal (laying head). On the one hand, the Aluminium rod is preformed before

entering the collection basket; on the other hand, the end of rod drops down into the basket automaticallyy

in case rod broken.

* 传动系统采用直流电机全数字式调速。全线控制采用可编程序控制器(PLC)与人机界面触摸屏,可以对铸锭温度、开轧温度、

乳液温度、淬冷用水温度温度进行显示;以及检测和显示设备的运行参数和故障显示。

The transmission system is in type of DC motor (fully-digital) speed adjusting. By adopting PLC and man-machine

interface for the complete line control, it can display the different kinds of temperatures, such as the cast

bar, the beginning of rolling, emulsion and water for quenching. Also it can check and display the running

parameter of machines as well as indicate the breakdown.

4.技术数据(Technical Data)

熔化炉 类型(Type) 竖炉(shaft furnace)

Melting furnace 熔化率(Melting rate) 5 t/h

保温炉 类型(Type) 液压倾动式(hydraulic tilting-type)

Holding furnace 炉容量(Capacity) 2×9 t

过滤除气装置 处理气体(Treatment gas) 氮气或氩气(nitrogen or argon)

Filter & degassing device 处理能力(Treatment capacity) 30-100 kg/min

除气效率(Degassing efficiency) 50-70 %

容量(Container capacity) 440 kg

连铸机 铸轮直径(Casting ring dia.) 1500 mm

Casting machine 铸坯速度(Casting bar speed) 8 - 12 m/minn

铸坯截面(Casting bar section) 2300 mm2

冷却水耗量(Water consumption) 90 m3/h

铸轮电机(Motor for casting ring) 4 kW

辅助液压剪 最大剪切力(Max. shearing force) 14000 Kg

Accessory shearer 最大剪切行程(Max. shearing stroke) 85 mm

校直机 校直轮数(No. of straightening roller) 5

Straightening machine 牵引电机(Pulling motor) 3 kW

感应加热器 输出频率(Output frequency) 350 Hz

Induction heater 输出功率(Output power) 300 Kw

冷却水消耗量(Water consumption) 15 m3/hh

连轧机 类型(Type) 粗轧为平立式二辊机架(2-high mould in rough rolling stand)

Rolling mill 精轧为三辊式机架(3-high mould in final rolling stand)

出杆直径(Outlet rod dia.) 9.5 mm

机架数量(No. of rolling stand) 14 pcs

轧辊直径(Rollers' dia.) 255 mm

终轧速度(Finished rolling speed) 4 - 6 m/ss

生产能力(Production capacity) 2.6 - 4 t/h

轧机中心高(Center height) 1052.5 mm

主电机(Main motor) 355 kW

乳化液消耗量(Emulsion consumption) 60 m3/h

淬冷装置 淬冷包数量(Rod quenching tunnel) 8 pcs

Rod quenching device 出杆温度(Outlet rod temperature) < 100 ℃

冷却水消耗量(Water consumption) 60 m3/h

双筐收杆机 牵引速度(pulling speed) 6.94 m/s

Twin-coiler 牵引电机(pulling motor) 7.5 kW

成圈直径(Coil's size) φ1500×φ2300 mm

成圈电机(Laying head motor) 4 kW

收杆筐尺寸(Collecting basket) φ2300×1300 mm

收杆重量(Coils’weight) 1500-1800 kg

5.生产线组成(Line Composition)

生产线主要由熔化竖炉,倾动式保温炉,过滤除气装置,连铸机,辅助液压剪,校直机,感应加热器,连轧机,润滑油系统,

乳化液系统,连续淬冷装置,双筐收杆机和电气控制系统等组成。

It is composed of melting shaft furnace, (tilted) holding furnace, filter & degassing unit, casting machine, accessory

oil-hydraulic shearer, cast bar straightening machine, induction heater, rolling mill, engine oil lubrication system,

emulsion lubrication system, rod quenching device, twin-coiler, line electric control, etc.