4英吋TFT液晶顯示屏

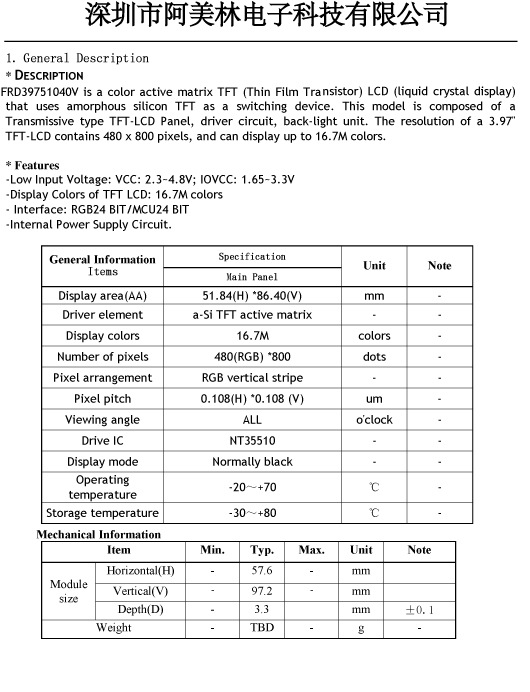

1 General Deion

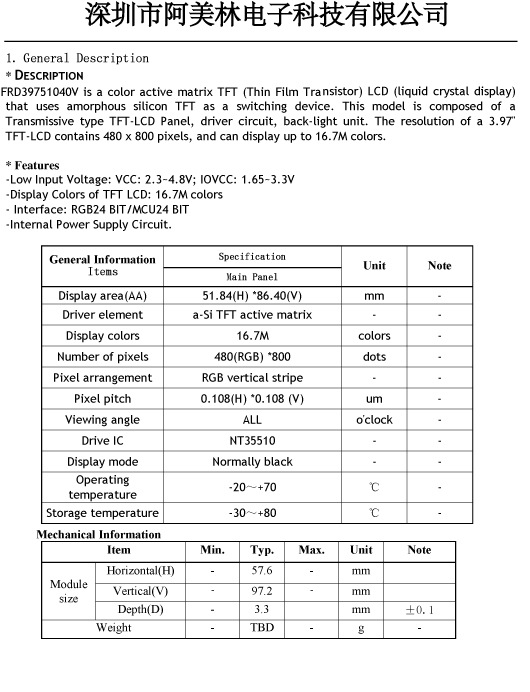

FRD397BP4510 is a transmissive type a-Si TFT-LCD (amorphous silicon thin film transistor liquid

crystal display) module, which is composed of a TFT-LCD panel, a driver circuit a backlight unit, The

panel size is 3.97inch and the resolution is 480x800. High image quality a-Si TFT LCD module.

Partial-screen display function is available. Sleep and Stand-by modes are available for power saving.

11.Precautions

Please pay attentions to the followings as using the LCD module.

Handling

(a) Do not apply strong mechanical stress like drop, shock or any force to LCD module. It

may cause improper operation, even damage.

(b) Because the polarizer is very fragile and easy to be damaged, do not hit, press or rub the

display surface with hard materials.

(c) Do not put heavy or hard material on the display surface, and do not stack LCD modules.

(d) If the display surface is dirty, please wipe the surface softly with cotton swab or clean

cloth.

(e) Avoid using Ketone type materials (e.g. Acetone), Toluene, Ethyl acid or Methyl chloride

to clean the display surface. It might damage the touch panel surface permanently. The

recommended solvents are water and Isopropyl alcohol.

(f) Wipe off water droplets or oil immediately.

(g) Protect the LCD module from ESD. It will damage the LSI and the electronic circuit.

(h) Do not touch the output pins directly with bare hands.

(i) Do not disassemble the LCD module.

(j) Do not lift the FPC of Touch Panel.

Storage

(a) Do not leave the LCD modules in high temperature, especially in high humidity for a long

time.

(b) Do not expose the LCD modules to sunlight directly.

(c) The liquid crystal is deteriorated by ultraviolet. Do not leave it in strong ultraviolet ray for

a long time.

(d) Avoid condensation of water. It may cause improper operation.

(e) Please stack only up to the number stated on carton box for storage and transportation.

Excessive weight will cause deformation and damage of carton box.

Operation

(a) When mounting or dismounting the LCD modules, turn the power off.

(b) Protect the LCD modules from electric shock.

(c) The Driver IC control algorithms stated above should always obeyed to avoid damaging

the LSI and electronic circuit.

(d) Be careful to avoid mixing up the polarity of power supply for backlight.

(e) Absolute maximum rating specified above has to be always kept in any case. Exceeding it

may cause non-recoverable damage of electronic components or, nevertheless, burning.

(f) When a static image is displayed for a long time, remnant image is likely to occur.

(g) Be sure to avoid bending the FPC to an acute shape, it might break FPC.

(h) Most of the touch screens have air vent to equalize the inside air pressure to the outside

one. The air vent must be open and liquid contact must be avoided as the liquid may be

absorbed if the liquid is accumulated near the air vent.

(i) For the fragility of ITO film, it should avoid to use too tapering pen as the input material.

Touch Panel Mounting Notes

(a) If a cushion is used between bezel/housing and film must be choose as free as enough to

absorb the expansion and contraction to avoid the distortion of film.

(b) The cushion must be placed out of the Viewing Area.

(c) Bezel/Housing edge must be posited between Key Area and Viewing Area. The edge

enters the Key Area may cause unexpected input if the gap is too narrow or foreign

particles like dusts exist between Bezel/Housing and ITO film.

Others

a) If the liquid crystal leaks from the panel, it should be kept away from the eyes or mouth.

b) For the fragility of polarizer, it is recommended to attach a transparent protective plate

over the display surface.

c) It is recommended to peel off the protection film on the polarizer slowly so that the

electrostatic charge can be minimized.

12. Incoming inspection standard

12.1 Deion

These inspection standards shall be applied to 3.5IPS(CMI panel) supplied by

FRIDA co.,ltd

12.2 The environmental condition of inspection

The environmental condition and visual inspection shall be conducted as below

(1) Ambient temperature:15~25℃

(2) Humidity:25~75%RH

(3) External appearance inspection shall be conducted by using a single 20W

fluorescent lamp or equivalent illumination.

Cell visual inspection on the operation condition for cosmetic shall be conducted

at the distance 35cm or more between the LCD Cell and eyes of inspector. And, the

visual inspection viewing angle should be with in the 45o to perpendicular line

Ambient Illumination: 400~600 Lux for external appearance inspection.

Ambient Illumination:100~200 Lux for light on inspection.

12.3 Inspection criteria

Definition of dot defect

Definition of defect

a) The definition of dot: The size of a defective dot over 1/2 of whole dot

is regarded as one defective dot, and all brightness or dark dot

defect must be visible through ND 5% filter

b) Bright dot: Dots appear bright and unchanged in size in which LCD

Cell is displaying under black pattern.

c) Dark dot: Dots appear dark and unchanged in size in which LCD Cell

is displaying under pure red, green, blue picture.

d) 2 dot adjacent=1pair=2dots