離心通風機

Centrifugal Fan

4-72-11 B4-72-11

Type 4-72-11 B4-72-11

使用說明書

Operation Instruction

用 途

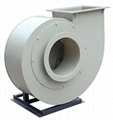

4-72-11型離心通風機(以下簡稱風機)是一種低中壓風機,它使用範圍很廣,壓力曲線平坦,便於安裝和維修,造價低廉,在風機名目繁多、群星匯萃的今天,4-72-11型風機仍不失為風機的“中流砥柱”,它主要承擔一般工廠、倉庫。高層建築、地下鐵道等大型建築物的通風換氣,並經常出現在如北京地鐵——這些人涌如潮、眾命尤關的主要和關鍵場合。它既可以輸出氣體,也可以輸入氣體,但被輸送氣體必須是空氣或其它不自燃。

不揮發、不易爆、對鋼材無腐蝕性、對人體無害之氣體,氣體內不得含粘性物質,所含塵土及硬質顆粒物在被輸送氣體中所占比例不得超150mg/m3,而且被輸送氣體之溫度不得超過80C。

B4-72-11型離心通風機又稱防爆離心通風機(以“B”表示),則可輸送易燃、易爆易揮發氣體,其空氣性能、外形尺寸、地基尺寸、內部結構均與同一機號的 4-72-11完全相同,但是動力須改為防爆電機,葉輪應用鋁材製造,以防萬一因葉輪歪斜而與機殼摩擦起火,開關應該用防爆開關或開關遠離易爆點,以防開關打火引爆。在易爆區內所有電線不許有接頭,以防“虛接”起火,電線應裝在鐵管內。

B4-72-11型離心通風機經常用在礦山、隧道、化工等場合。

F4-72-11型離心通風機則可輸送對鋼鐵有腐蝕性,對人體有害及含毒之氣體,這種風機凡可能與被輸送氣體接觸之部件,如:機殼、葉輪、進風口、出風口等均應用抗腐蝕性材料,如不鏽鋼、玻璃鋼以及其他抗腐蝕材料製造。其空氣性能、外形尺寸、地基尺寸、內部結構、動力等與同一機號的4-72-11完全相同。它經常應用在化工廠、鍍鋅廠、化肥

廠等重要場合。

型 式

在一般情況下,4-72-11型離心通風機有2.8A、3.2A、3.6A、4A、4.5A、5.6A、6A、6C、6D、8C、8D、10C、10D、12D、16B、20B共13個機號,18個品種。其中任何一個機號的任何一種傳動,皆可作成“左”旋或“右”旋兩種型式。從電機一端正視葉輪,凡順時針旋轉者皆稱“右旋風機”,以“右”表示,反之皆稱“左旋風機”,以“左”表示。

風機的出風口位置以機殼的出風口角度表示,其中:№8~6A在出廠時均做成一種型式,使用單位根據要求再安裝成所需要的位置,訂貨時無須註明。

特別注意:①№2.8A出風口調整範圍是0°~225°,間隔是45°;

②№3.2A~6A、6C、6D出風口調整範圍是0°~225°,間隔是22.5°;

③№8D~10C、D出風口調整範圍是0°~180°間隔是45°;

④№12C、D出風口調整範圍是0°~180°,間隔是15°;

⑤№l6B、20B出風口角度製成0°、90°、180°“固定的三種,不能調整,訂貨時須註明用哪一種。

⑥上述出風口角度是風機行業的習慣做法,如這些做法不能滿足您的具體使用環境和條件,我廠可以為您做成令您滿意的角度,出現這種情況時,本說明書後邊的安裝尺寸表可能會有所變動,望用戶注意。

風機的傳動方式為有A、B、C、D四種:

A一表示風機軸盤通過鍵槽安裝在電機軸伸上,即電機直插;

B一表示懸臂支承裝置,皮帶傳動,皮帶輪在兩軸承中間;

C一表示懸臂支承裝置,皮帶傳動,但是皮帶輪在軸承外側;

D一表示懸臂支承裝置,用聯軸器聯接驅動。

在風機行業的習慣性做法中,4-72-11№2.8~5做成A式,№6既有A式,也有C式和

D式,№8~12既有C式,也有D式,№16、20僅有B式。

這些傳動方式一般均能滿足用戶的使用要求,當萬一不能滿足您的要求時,我廠有實力設計和生產使您滿意的風機。

結 構

風機一般主要由葉輪、機殼、進風口和傳動部分組成,但№2.8~6A為A式傳動,無傳動組。

葉 輪 一 它是風機的核心部件,它的材質和型線決定了一颱風機的風壓、風量。能耗、噪聲和壽命。本風機由十個后傾的機翼型葉片、曲線型輪蓋和平板后盤組成,根據不同用途和介質用普通鋼板、16錳鋼、不鏽鋼或玻璃鋼製造,經動靜平衡校正和超速運轉實驗,運轉平穩可靠,空氣性能良好。

機 殼 一 機殼做成兩種不同型式,其中:№2.8~12機殼做成整體,不能拆開。№16~20機殼沿水平做成上下兩開式,上半部沿中心線垂直分為兩半,用螺栓連接,主要是考慮便於拆卸、維修和移動,具體材質根據風機的用途或普通鐵板焊成,或用不鏽鋼焊成,或用玻璃鋼加工而成,當然工藝、造價和工期也隨之不同。

進風口 一 進風口製成整體結構,它與軸向平行的截面為曲線形狀,便於氣體順利進入葉輪且損失較小,進風口通常用螺栓固定于風機一側。進風口與葉輪在徑向和軸向間隙太小了稍有不慎會造成摩擦,太大時會造成漏風,影響效率,請保証設計尺寸。

傳 動 一 傳動部分由主軸、軸承箱、滾動軸承、皮帶輪或聯軸器組成。

性能

風機的性能通常用流量、全壓、主軸轉速、軸功率、效率等參數表示,這些參數間

有一定的換算關係,其關係可用性能曲線,數學公式或表格等方式表示;

如果設 Q 一 流量 m3/h; H 一 全壓 Pa;

N 一 軸功率 kW; η一 全壓效率

ηm一 機械效率 %; r 一 比重 kg/ m3;

n 一 主軸轉數 r/min; t 一 溫度 ℃

式中:

帶註腳“2”的表示已知性能參數,帶註腳“1”的表示未知性能參數。

那麼:

風機性能一般均指標準狀況下的性能,當使用狀況與標準狀況不符時須把此時的性能換算

成標準狀況下的性能,然後再查性能表選擇機號和轉速。所謂註標准狀況是指:

大氣壓力P=101325 Pa 自由落體加速度g=9.8 m/sec2

空氣密度 ρ=0.1223 kg·se c2/m4 大氣溫度 t=20℃

所需功率按下式求出:N=10-3η-1·K ·Q·H 相對濕度&=50%

A、D、C各種傳動效率值

傳動方式 機械效率ηm

A 電機直聯

D 聯軸器

C 皮帶傳動

K值的選取

電機功率kW K值

0.5以下

>0.5~1

>1~2

>2~5

>5 1.5

1.4

1.3

1.3

1.15

流量 的調 節

在使用時,常常發生流量過多或不足的現象,產生這種現象的原因很多,如果是在使

用過程中發生流量時大時小的現象,主要是由於管網中阻力時大時小或風機在飛動區工作

的緣故;如果是在使用過程中經過較長時間逐漸減少或在短時間內突然減少,則主要是由

于管網堵塞。

在風機新安裝后,進行正式試運轉時就發生流量過大或不足現象,產生這種現象的原因主要有下列幾點:

1.管網阻力實際值與計算值相差過大。

一般管網特性方程式為:

H=K·Q2 式中:K一 阻力係數

如實際值K小於計算值K時,則流量增大;若實際值K大於計算值K時則流量減少,見圖1(b)。

2.選擇時未考慮風機本身全壓值偏差aH的影響,當風機實際全壓為正偏差時,則流量增大;為負偏差時,則流量減少,見圖1(a)。

Fig. Pipe net characteristic curve

在風機新安裝后開始正式運轉時或在使用過程中發生流量過大或過小時,可採用下列方法之一消除之:

(1)利用節流裝置的啟閉度以調節流量。

(2)利用增減風機的轉速以增減流量。

(3)利用調換新的壓力較高或較低的風機以增減流量。

(4)改變管網使管網阻力係數K減小或增大流量。

必須指出的是:一般都是採用節流裝置來調節流量,但當實際流量比需要流量大的很多時,這種方法浪費電力過多,很不經濟,如果條件允許時,通常採用降低風機轉速或調換壓力較低的風機。

當節流裝置全開時,流量仍嫌過小,此時節流裝置己失去節流作用,故應設法減小管網阻力係數以增加流量,也可採用增高風機的轉速和調換壓力較高風機,但電動機直聯和聯軸器直聯的風機一般都不能改變轉速,只有皮帶傳動的風機可借改變皮帶輪直徑的大小以增減轉速,切記風機的最大轉速不得超過性能與選用件表之最高轉速。

說明:(1)Ng10、12、16、20按Ng10模型的無因次性能換算。

2)Nils、6、8按Nd模型的無因次性能換算。

(3)Ngs以下按實測樣機性能確定。

無固次性能曲線換算為有因次的計算公式為:

全 壓 H=p·V“·H(Pa)

流 量

軸功率 (kW)

式中:D一葉輪外徑(m)u一葉輪外圓線速度(。/s)0一氣體密度(ks/m’)

所需功率等於軸功率另加機械損失和電機儲備量。

安裝與使用

在安裝前首先應準備好材料和工具,對風機各部機件進行全面核對,對葉輪、機殼、主軸和軸承等機件更應特別細緻檢查,如發現損傷,應予修復,然後用煤油清洗軸承箱內部。

在進行固定操作過程中必須注意以下幾點:

1.在一些接合面上,為了防止生鏽,減少拆卸困難起見,應塗上一層潤滑油或機械油。

2.在上接合面的螺栓時,如有定位銷釘應先上好銷釘,再擰緊螺栓。

3.檢查機殼內及其它殼體內部,不應有掉入和遺留的工具或雜物。

安裝時的具體要求是:

1. 安裝時,嚴禁儿童、老人、殘疾人等行動不便者或無關人員在場圍觀。

2.按先安裝風機,后接通電源的次序進行。

3.安裝風機時,輸氣管道的重量不應加在機殼上。

4.按圖紙校正進風口與葉輪之間間隙尺寸,而且保持軸的水平度。

5.安裝進風口管道時,可以直接利用進風日本身的螺栓進行連接,此時進風口固定是靠三個沉頭螺釘。

6.安裝Nil6D~Ng12D式風機時,利用千分表和塞尺,測量風機主軸和電機軸的同軸度及聯軸器兩端平行度。兩軸同軸度允差為0.05nun。聯軸器端面平行度允差為0.Inun。

7.風機安裝完后,用手或槓桿撥動轉子,檢查是否有過緊或刮蹭等現象。在無過緊或刮蹭的情況下方可進行試運轉。

8.電動機安裝后,安裝皮帶輪或聯軸器防護罩,如進氣口處不接進氣管道時,也需加防護網或其它安全裝置(用戶自備)。

其它部件,按圖紙對應位置進行安裝。

由於風機的流量Q、全壓H、主軸轉數n、軸功率N四者有固定關係:

因此在電動機容量不改變時,主軸轉速不宜更改,若主軸轉速增大,電動機則有因過載被燒之危險。

通風機所採用的電機功率,系指在特定的工況下,軸功率加上機械損失與應有的儲備量而言,並非出風日全開時所需功率,如風機的出口或入口不接管路或未加外界任何阻力而進行空轉,則電機亦有被燒之危險。為安全起見,應在風機的出口或入口管路中加裝閥門,起動電機時將其關閉,運轉后將閥門慢慢開啟,直至規定工況,並注意電流是否超標。

維 護

l、風機不許帶病運行。

2、風機的維護和修理必須在停機斷電、風機確實停穩后進行。

3、維護人員不許隨意更換,應保持相對的穩定,最好專人使用,專人維護。

4、在修理風機時電機開關須有專人監護或上鎖。

5、定期清除風機及管道內部的灰塵、污垢及水等雜質,並防止鏽蝕。

6、對溫度計及油標的靈敏性應定期檢查。

7、除每次拆修后更換潤滑油外,還應定期更換潤滑油。

A、D、C各種傳動效率值

傳動方式 機械效率ηm

A 電機直聯

D 聯軸器

C 皮帶傳動 1.00

0.98

0.95

K值的選取

電機功率kW K值

0.5以下

>0.5~1

>1~2

>2~5

>5 1.5

1.4

1.3

1.3

1.15

故障原因一覽表

故障 原因

軸承箱體

振動劇烈 1.風機軸與電機軸不同心,聯軸器歪斜。

2.機殼或進風口與葉輪摩擦。

3.基礎的剛度不夠或不牢固。

4.葉輪鉚釘鬆動或輪盤變形。

5.葉輪軸盤與軸鬆動,聯軸器螺栓活動。

6.機殼與支架、軸承箱與支架、軸承箱蓋與座等聯按螺栓鬆動。

7.風機進、出氣管道的安裝不良,產生振動。

8.轉子失衡。

軸承溫

升過高 1.軸承箱振動劇烈。

2.潤滑脂質量不良、變質或填充過多和含有灰塵、粘砂、污垢等雜質。

3.軸承箱蓋、座聯接螺栓之緊力過大或過小。

4.軸與滾動軸承安裝歪斜,前後兩軸承不同心。

5.滾動軸承損坏。

電動機電

流過大和

溫升過高 1.開車時進氣管道內閘門或節流閥未關嚴。

2.流量超過規定值或風管漏氣。

3.風機輸送之氣體密度過大或含粘性物質。

4.電動機輸入電壓過低或電源單相斷電。

5.聯軸器聯接不正,皮圈過緊或間隙不勻。

6.受軸承箱振動劇烈的影響。

7.受並聯風機工作情況惡化或發生故障的影響。

皮帶滑下 兩皮帶輪子位置彼此不在一中心線上,使皮帶從小皮帶輪上滑下。

皮帶跳動 兩皮帶輪距離太近或皮帶過長

Centrifugal Fan

Type 4-72-11 B4-72-11

Operation Instruction

表 頭 中 的 中 英 文 對 照

Performance and Optional Part Table of Centrifugal Fan………離心風機性能與選用件表

Speed……………………………………………………………轉速

Driving Mode……………………………………………………傳動方式

No.………………………………………………………………序號

Flow………………………………………………………………流量

Total Pressure……………………………………………………全壓

Inner Effic..………………………………………………………內效率

Inner Power………………………………………………………內功率

Req. Power………………………………………………………所需功率

Motor……………………………………………………………電動機

Type………………………、……………………………………型號

Power……………………………………………………………功率

Triangle Belt………………………………………………………三角帶

Anchor Bolt………………………………………………………地腳螺栓

Nut.………………………………………………………………螺母

Washer.…………………………………………………………墊圈

I.C.………………………………………………………………內周長

Shaft Pulley………………………………………………………主軸皮帶輪

Code………………………………………………………………代號

Size………………………………………………………………規格

Motor Pulley………………………………………………………電機皮帶輪

Motor Rail…………………………………………………………電機導軌

(Set)………………………………………………………(套)

Installation and Overall dimension of Centrifugal fan…………離心通風機安裝及外形尺寸

Machine No. …………………………………………………機號

Intake…………………………………………………………進風口

Discharge…………………………………………………… 出風口

Connecting Bolt………………………………………………連接螺栓

Size……………………………………………………………規格

Quant. ………………………………………………………數量

Bolt Hole………………………………………………………螺栓孔

Dia. …………………………………………………………直徑

Distance………………………………………………………間距

Installation and Overall dimension……………………………安裝及外形尺寸

Impeller Weight………………………………………………葉輪重量

Fan Weight(Motor Excl)…………………………………風機重量(不包括電機)

Motor Weight…………………………………………………電動機重量

Installation……………………………………………………安裝

Right,……………………………………………………………右

Purpose

Type 4-72-11 centrifugal fan (below calls fan) is a kind of low and middle pressure fan, it has a wide service range, flat pressure curve, facilitate to install and repair, and low in price. In the current, there are multitude of items for fan, Type 4-72-11 is still ”a firm rock in mainstream ” of fan, it undertakes the ventilation of general factories, warehouses, high buildings and subways etc. and often appears on the main occasion such as Beijing Subway, it can output or input gas, but the gas handled by fan must be air or other gas which is non-inflammable, non-volatile, non-explosive, non-corrosive to steel and harmless to the people, visco-material shouldn’t be contained in the gas. Dust and hard particle content in the gas is not greater than 150 mg/m3, the gas temperature shall not exceed 80℃.

Type B4-72-11 centrifugal fan also calls explosion proof centrifugal fan (symbolized with “B”), can handled combustible, explosive and volatile gases, its aerodynamic performance, overall dimension, foundation dimension and internal structure are the same as Type 4-72-11, but power must be changed to explosion proof motor power, impeller is made of aluminium in order to prevent impeller friction with casing to catch fire, explosion proof switch is used and it must be far a way from the explosive point in order to prevent switch striking sparks and igniting. In the explosive area, all wires must not have connector in order to prevent virtual connection and catch fire, wire should be installed into iron pipe.

Type B 4-72-11 centrifugal fan is usually used in mine, tunnel and chemical industry.

Type F 4-72-11 centrifugal fan can handle the gas which is corrosive to iron and steel, harmful to people and toxic.

All parts, such as casing, impeller, inlet are made of corrosion resisting materials, such as stainless steel, glass fiber reinforced plastics and other corrosion resisting materials. Its aerodynamic performance, overall dimension, foundation dimension, internal structure and power are the same as Type 4-72-11. It often appears on the main occasions of chemical industry plant, zinc plating plant and chemical fertilizer plant etc.

Type

In normal condition, type 4-72-11 centrifugal fan has 13 different sizes and 18 varieties, they are 2.8A, 3.2A, 3.6A, 4A, 4.5A, 5.6A, 6A, 6C, 6D, 8C, 8D, 10C, 10D, 12D, 16B, 20B. One of them can be made of two types rotation i.e. right and left, viewing from one end of the motor, it is called as clockwise fan if the impeller rotates clockwise, and symbolized with “right”, on the contrary, it is called as counter clockwise fan if the impeller rotates counter clockwise, and symbolized with “left”. The outlet position of the fan can be expressed from the outlet angle of the casing, among them, No. 2.8~6A is made of a kind of angle 0°, user can change the angle according to the requirement, without note when ordering.

Special note: 1.Adjustment of angles for No. 2..8A outlet is 0°~225°, the interval is 45°;

2.Adjustment of angles for No. 3.2A~6A, 6C, 6D outlets is 0°~

225°, the interval is 22.5°;

3.Adjutment of angles for No. 8D~10C, D outlets is 0°~180°, the interval is 45°;

4.Adjustment of angles for No. 12C, D outlets is 0°~180°, the interval is 15°;

5.No. 16B, 20B outlets can be made three kinds of angles which are

0°,90°,180°and can not be adjusted, note when ordering.

6.The mentioned outlet angles is the customary doing of the fan trade, if they can’t meet your specific environment and condition, our factory can manufacture satisfactory angles for you, if this situation occurs the installation dimension behind the manual may be changed, users should take notice.

There are 4 driving modes: A,B, C, D:

A— Shaft disc of fan is installed on motor shaft by keyway, i.e. motor directly connecting;

B—Cantilever bearing unit, belt driving, pulley is in the middle of two bearings;

C—Cantilever bearing unit, belt driving, but the pulley is outside the bearing;

D—Cantilever bearing unit, coupling directly driving.

In the fan trade customary doing, type 4-72-11 No. 2.8~5 take mode A, No. 6 takes modes A, C and D, No. 8~12 take modes C and D, No. 16, 20 take only mode B.

Generally these driving modes can meet users operating requirement, if they can’t meet your requirement, our factory has ability to design and manufacture satisfactory fan for you.

Structure

The fan mainly consists of impeller, casing, inlet and driving unit, but No. 2.8~6A is mode A driving, and without driving unit.

Impeller—it is the key part of the fan, its material and contour can determine the wind pressure, flow rate, power consumption, noise and service life. The impeller consists of 10 backward wing blades, a curved front disc and flat rear disc, they are made up of steel plate, 16 Mn stainless steel or glass fiber reinforced plastics according to the various purpose and medium, the impeller shall be balanced statically and dynamically, over speed running test is carried out, and thus it has smooth running and the aerodynamic performance is good.

Casing—it shall be made two kinds of different types, among them: No. 2.8~12 casing is made in integral type, it can not be disintegrated. No.16~20 casing is made in three-open type, besides the casing is divided into two parts along the split horizontal level, the upper casing is vertically divided into two parts again along the centerline, and they are fixed by bolts, and thus facilitate to disassembly, repair and move. It is welded with normal iron plate or stainless steel, or machined with glass fiber reinforced plastics according to the purpose of the fan, however technology, price and schedule are also different.

Inlet—the inlet is manufactured as an integral type, the section which is parallel to the shaft is curved forms and gas is allowed into the impeller smoothly with a little loss, the inlet is generally fixed on the side of the fan with bolts. Radial and axial clearances between inlet and impeller are too small, friction can be caused between them, and when the clearances are too big, air leakage can be caused between them, please keep the design dimensions.

Driving unit—it consists of shaft, bearing box, rolling bearing, belt pulley or coupling.

Performance

The Performance of the fan is symbolized by flow, total pressure, speed, power, efficiency and Parameters etc.. there are certain conversional relations between these parameters, the relation can be shown by performance curve, mathematical formula and form mode etc;

Q—Flow rate m3/h; H—total pressure Pa;

N—Shaft power kW η—total pressure efficiency

ηm—mechanical efficiency % r—specific gravity kg/m3

n—speed r/min; t—temperature ℃

where:

with footnote 2 symbolizes the known parameter,

with footnote 1 symbolizes the unknown parameter.

then:

The performance of the fan normally indicates the performance under the standard state. When the operating condition is inconsistent with standard state, at this moment the Performance must be converted into the performance under the standard state. The so-called standard slate indicates: atmospheric pressure P=101325 Pa, acceleration of gravity g=9.8m/sec2, air density ρ=0.1223kg·sec2/m4, atmospheric temperature t=20℃, the required power N=10-3η-1·K·Q·H, the relative humidity &=50%.

A、D、C driving efficiency value

driving mode Mechanical

efficiencyηm

A motor driving

D coupling driving

C belt driving 1.00

0.98

0.95

Selection of value k

motor power (kW) value k

below 0.5

>0.5~1

>1~2

>2~5

>5

1.5

1.4

1.3

1.3

1.15

Adjustment of Flow rate

The phenomenon of flow excess or insufficient often occurs in operation, there are many reasons in occurring such phenomenon. If the phenomenon of flow rate sometimes great and sometimes little occurs during operation, the main reason is due to resistance in pipe net sometimes strong and sometimes weak. If it is gradually reduced through a long period or suddenly reduced within a short time, the main reason is that the fan passage or pipe net is pl ed. The phenomenon of flow excess or insufficient will occur during normal running after installing, the main reason is as follows:

1.The actual and theoretic values k of resistance in pipe net is widely different. It was known normal pipe net characteristic equation H=KQ2, where: k is the coefficient of resistance, if the actual value k is less than the theoretic value k, the flow rate increases; vice versa, flow rate decreases, see Fig. 1 (b)

2.The effect of fan total pressure deviation △p have not been considered during selecting. when the actual total pressure of fan is a positive deviation, the flow rate increases, and when it is a negative deviation, the flow rate decreases, see fig 1 (a).

Fig.1 Pipe net characteristic curve

The flow rate excess or in sufficient occurred after fan newly installing and putting into operation, one of the following methods can be used to eliminate:

(1) Flow rate can be adjusted by damper.

(2) Increasing or decreasing the speed of the fan.

(3) Changeover a higher or lower pressure fan.

(4) Changeover pipe net to reduce the coefficient k of resistance.

It must be pointed out: flow rate is normally adjusted by damper, but when the actual flow rate is much greater than the required, it wastes power, it is not economical, if the condition permits reducing fan speed or changing-over a lower pressure fan is normally used.

When the damper is full open, the flow rate is still insufficient, at this moment, the damper has lost its function, so try to reduce the resistance coefficient of pipe net, or increase the speed of the fan, or change-over a higher pressure fan, but the fan driven by motor and coupling can not be normally changed the speed, only the fan driven by belt, the speed can be increased and decreased by the means of changing the size of belt pulley diameter, the max. speed must be lower than the performance and optional part table required.

Note:

(1) No. 10,12,16 and 20 is converted according to the non-dimensional performance of No. 10 model.

(2) No. 5, 6 and 8 is converted according to the non-dimensional performance of No. 5 model.

(3) No. 5 below is determined by the actual testing sample fan performance.

The dimensional formula which converted by non-dimensional performance curve is :

Total pressure (Pa)

Flow rate

Power (kW)

Where:

D—outer diameter of impeller (m) μ—linear velocity of impeller outer circle (m/s) ρ—air density (kg/m3)

The required power is equal to shaft power plus mechanical loss and motor storing quantity.

Installation and Operation

First, prepare attachment and tools before installation, then, check every parts of the fan, impeller, casing , shaft and bearing etc. should be inspected carefully, if damages are found, repair should be carried out, and then clean inside of the bearing box with kerosene.

The following points must be noted during installation:

1. Lubricating oil or mechanical oil should be coated on the joint surface in order to prevent rust.

2. When the bolt is screwed in the joint surface, if there are setting dowels, doweling the joint surface first, and then tighten the bolt.

3. Pay attention to check the casing and any tools or goods should not be dropped and remained inside the casing.

Requirements of installation:

1. During installation, prohibit children, old people, disabled person and the persons who has difficulty getting about a bit on the installing site to surround and watch.

2. Install the fan first and then switch on power supply.

3. During installation, the weight of air duct should not added on the casing of the fan.

4. Correct the dimensions between the impeller and the inlet according to the drawing, keep the horizontality of the shaft.

5. When installing the inlet pipe, the bolt of inlet is directly used to connect pipe, at this time the inlet is fixed by three countersunk screws.

6. During installing No. 6 D~No. 12 D, the coaxality of fan shaft and motor shaft and the parallelism of both ends of coupling are measured by dial gage and feeler gage. The permissive coaxial error is 0.05 mm. The permissive parallelism error of coupling is 0.1mm.

7. Turn the rotor with hand or lever after installation to check whether it is over tight or touched with stationary components.

8. After installing the motor, install the belt pulley or coupling guard, if the inlet is not connected to the inlet pipe, the protective net or other safety device is also added (provided by user himself). Other parts of the fan are fixed according to the drawing.

Because of the flow rate Q, total pressure H, the shaft speed n, and shaft power N having the specific relations:

Thus, without changing the motor capacity, the shaft speed can not change, otherwise, the motor may be damaged by overload.

The motor power used by fan indicates under the specific operating condition, shaft power plus mechanical loss and storing quantity, but not the required power when the outlet full open, if the outlet or inlet of fan without connecting pipe or without outside resistance, the motor can not be put into operation. For the safety, a valve should be installed in the inlet and outlet pipes of the fan, close the valve when motor start up, the valve is slowly open after running, until reached the specific operating condition, and pay attention to the current if exceeds the rated value.

Maintenance

1. Don’t allow fan with trouble running.

2. Maintenance of fan can only be carried out during shut-down of fan.

3. Don’t freely change the maintenance person, specific person operating and repair the fan is preferred.

4. When the fan is repaired, the motor switch must be monitored or locked.

5. Regularly remove dust, contamination and the foreign materials and prevent rust.

6. Inspect the thermometer and oil indicator regularly.

7. Except replacing the lubricant after overall, replace the lubricating oil periodically.

List of troubles and causes

Troubles causes

Severe vibration of bearing box 1.The shaft of fan is not parallel with that of motor; the coupling is misalignment.

2.friction between casing or inlet and impeller.

3.The foundation is not rigid enough or firm enough.

4.loosing of rivets in impeller or deformation of impeller.

5.Loose matching of shaft with impeller main disc.

6.Loosing of the bolts which connect casing and bearing with support, bearing with its cover.

7.Installation of fan inlet and outlet ducts is improper, which causes vibration.

8.The rotor is unbalance.

High temperature-rise of bearing 1.Severe vibration of bearing box.

2.Lubricant is poor in quality, deteriorated, mixed with dust, sand, contamination and etc.

3.Connection of bearing box cover and pedestal is over tight or Loose.

4.Fixing position between shaft and rolling bearing is slant, the front and back bearing are out of alignment.

5.wornout of rolling bearing.

Over current and high temperature-rise in motor 1.Gate or damper in the inlet and outlet pipes are not closed when starting-up.

2.Flow rate exceeds the specific value or air duct leaks.

3.Air density delivered by fan is over strong or contain visco-materials.

4.Input voltage of motor is low or is cut out in a single phase.

5.Coupling connecting is out of alignment the belt is too tight or the clearance is not uniform.

6.Influence caused by severe vibration of bearing box.

7.Influence caused by fan in parallel operation condition is worse or trouble happened.

Belt sliding Two belts are not in the center line. The belt slides down from a small belt pulley.

Bet chattering The distance of two belt pulleys is too short or the belt is too long.