| Model: | recycling line |

|---|---|

| Brand: | orotrim |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | pp pe film recycling , film recycling line , pp film granulating |

| Price: |

-

|

| Min. Order: | 1 pc |

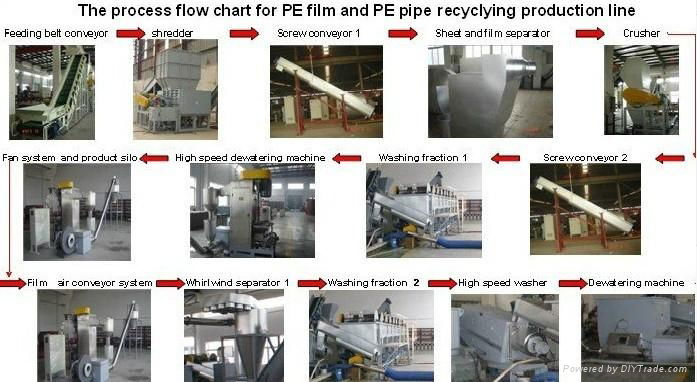

Product Description

1. high quality

2. use bimetal screw and barrel with 2-3years guarantee.

PP/PE plastic granules making machine. PP/PE recycling machine. pp/pe granulator:

Plastic granulator is an equipment to make film material, silk material or particles into plastic particles by extruding, cooling and pelletizing.

Characteristics:

This equipment is used together with granulator. Simply processes, advanced technology, and applied to different waste plastics. It uses the electric network, automatic temperature control and the state's patented energy-saving heaters with low power consumption, non-polluting, high degree of automation. And applied to different waste plastics. For the use of electric network, automatic temperature control, national energy-saving patented heater, low power consumption, non-polluting, high degree of automation.

This line you are now looking at is mainly used for PP/PE waste film recycling and washing. After films clean, you can use them to pelletize:

We can design different pp/pe film recycling line for you according to your request:

1: There are different capacity can be supplied: 200kg/h, 300kg/h, 500kg/h

2: You can choose different devices according to your material.

3: According to your country condition, you can choose full automatic line orsemi-automatic line.

4: You can purchase separate device based on your own conditions.

5: We providing turn-key project for you. Design-product-installment-testing.

Features and application:

1) This whole production line is used to crush, wash, dewater and dry PP, PE Film.

2) It takes the advantages of simple structure, easy operation, high capacity, low energy consumption, safety, reliability, etc.

Member Information

| orotrim texplas machinery limited | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Trading Company |

| Phone: | 15861654037 |

| Contact: | lucia (sale manager) |

| Last Online: | 20 Nov, 2012 |

Related Products of this Company

-

floor wpc frame inside or outside

-

plastic pp pipe extrusion machine

-

PS、EPS RECYCLING AND GRANULATION LINE

-

over-lap welding PE-AL- PEX pipe

-

PVC transparent sheet production line

-

high efficient plastic extruder

-

PE/PVC double-wall corrugated pipe

-

PVC PP PE wood plastic profile

-

WPC profile making machine

-

PE-RT PIPE PRODUCTION LINE