| Model: | TRVVYP-PUR |

|---|---|

| Brand: | Shanghai Youjiang |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Optical Fiber, Cable & Wire / Electric Wire & Cable |

| Label: | Polyurethane cable , Shielded cable , Resistant to wear an |

| Price: |

¥5.95

/ pc

|

| Min. Order: | 300 pc |

Product Description

Application:

Tow chain cables are widely used in steel, industrial furnace, machine, filter press, roll ring machine, pipe bender, trenchless directional drilling, oil drilling platform, hydraulic equipment, metallurgical equipment, steel equipment, steel pipe equipment, grouting machine, machine tool, CNC machine, vertical lathe, glass machinery, woodworking machinery, manipulator, cutting machine, engraving machine, doors and Windows machinery and so on high speed mobile occasions, suitable for dry or wet indoor and outdoor, no strong stress slow-release or forced lead free continuous reciprocating motion of the installation, industrial use environment of frequent bending occasions, such as woodworking machinery, machine tool processing equipment, logistics delivery system, crane occasions, to the electromagnetic shielding good anti-jamming.

Product features:

Waterproof, prevent oil, cold resistance, resistance to ultraviolet light, wear resistance, flame retardant

Bending life of 6 million or more. Suitable for fast moving occasion. This product is highly soft characteristics, widely used in as control, connecting the bending required control unit, dedicated to the continuous bending free to move without tension and forced motion of the drag chain system, at the same time can keep cable soft moving occasion requirements.

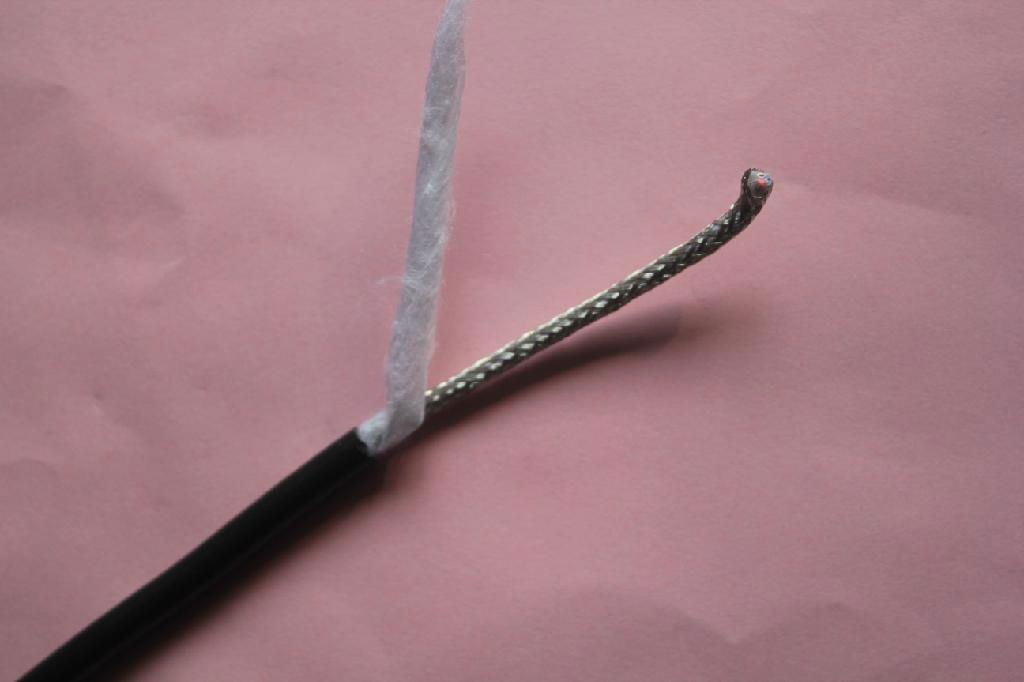

Cable structure:

Conductor: stranded super fine fine ground anaerobic copper wire, accord with VDE0295class6 standard

Insulation: special mixed PVC insulation

Color: 0.5 mm or less color said, brown, black, blue, purple, pink, orange

Or 0.5 mm black digital white number Numbers, 3 core above with yellow green ground wire (yellow green optional)

Inner sheath: special mixed plastic

Shield: tin plated copper wire braided shielding, density is more than 85%.

Sheath: special mixed plastic sheath

Orange (RAL2003) black (RAL9005) grey (RAL7001)

Rated voltage: or 0.5 mm: 300/500 v < 0.5 mm: 300/300 v

The test voltage: 2500 v

Using temperature range: fixed installation: ℃ to + 90 ℃

Mobile installation: - 25 ℃ to + 90 ℃

The minimum bending radius: fixed installation: 4 x cable diameter

Mobile installation: 15 × cable diameter

Section: 0.12 the best callus induction ~ 35 best callus induction

Some: 1 core ~ sixty core

Tow chain cable why bending 6 million times continuously

Tow chain cable mainly applies to industrial electronic system, automatic generation of line, storage equipment, robot, fire fighting system, crane, numerical control machine tool and metallurgical industry.

Our tow chain cable, in order to satisfy everytime traverse, more conventional cable usually has the following several parts:

1. Tensile center

In the center of the cable according to some quantity and each root conductor cross sections of the space as far as possible have a true center line filling (rather than normally, with some filler or made of plastic waste wire filling) this method can effectively protect the stranded wire structure, prevent stranded wire free to the central area of the cable.

2. The conductor structure

Cable should choose the most suppleness of the conductor, and generally conductor is fine, cable suppleness the better, but the conductor meticulous, can produce cable winding phenomenon. A series of long-term experiment provides the best single wire diameter, length and section to shield combination, it has the best tensile ability.

3. Core insulation

In the cable insulation materials can't each other viscous. And insulating layer also need to support a single strands of wire. So only in high pressure forming PVC or TPE material can used to tow chain of millions of meters cable in the process of the application of confirmed his reliability.

4. Stranded wire

Stranded wire structure must be with the best mating pitch around a stable tensile around the center. However, due to the application of insulating materials, stranding structure should be according to the motion state design, from the beginning, because the root wire the bundle twisted way.

5. Inner sheath

Harness type extrusion forming of inner sheath replace cheap wool materials, packing or subsidiary filler. This method can guarantee stranding structure not messy.

6. Shielding

With the optimization of the braided Angle will shield tightly woven, sheath outside, loose weave belt will reduce the EMC protection ability and shielding layer also soon because of the shielding of the fracture and failure. Tightly knit shielding layer at the same time it can resist torsion role.

7. Outer sheath

By different modified material made of outer sheath with different function, there is resistance to UV function, low temperature resistance, oil resistance function and cost optimization. But all of these outer sheath have one thing in common, high wear resistance, will not adhere to anything. Outer sheath must be high soft but also want to have support function, of course, should be high pressure molding.

With the development of the company, we are becoming more and more skilled craft, material for raw materials is more and more strict, we can have the confidence and strength to ensure that the product's bending frequency can be as high as 6 million times continuously core.

Member Information

| Shanghai Youjiang cable Co.,Ltd | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 13611794511 |

| Contact: | Miss Shang (Business Office) |

| Last Online: | 07 Mar, 2013 |