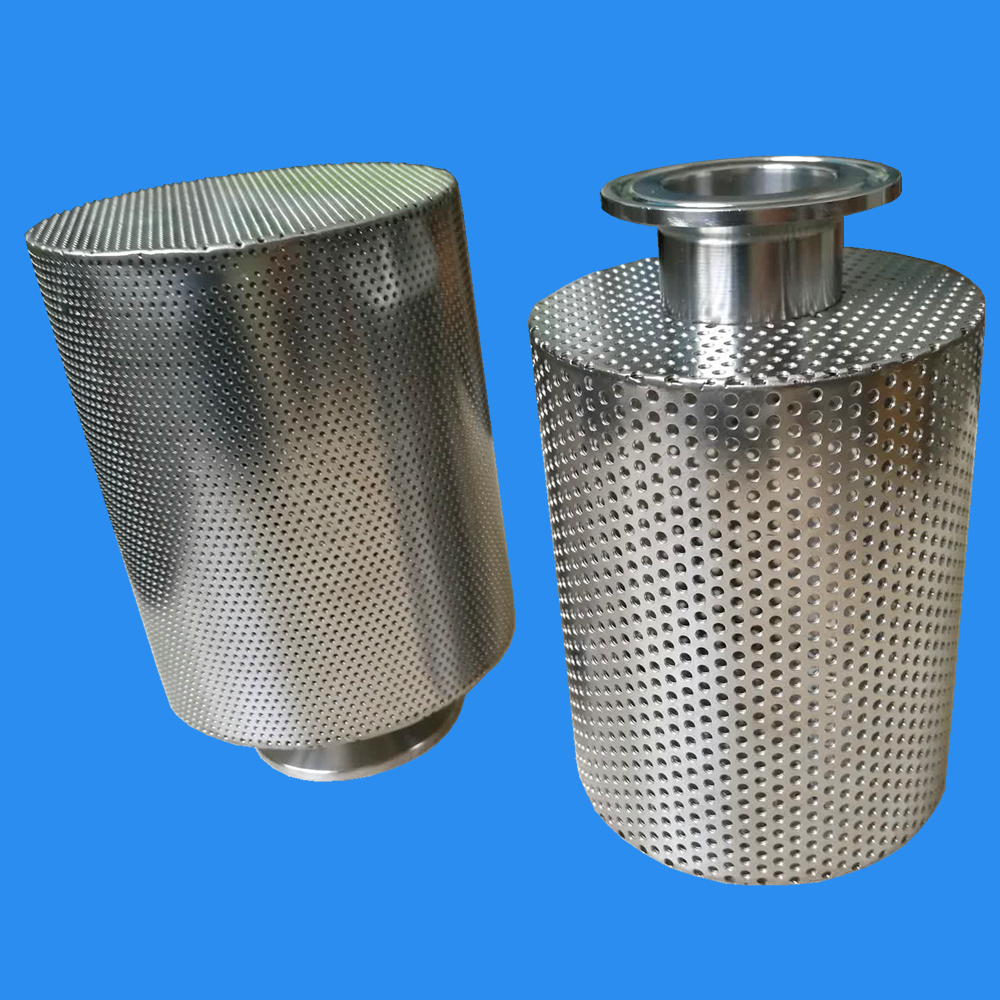

Stainless steel pleated filter element

Stainless steel pleated filter elements are widely used in environmental protection, petroleum, chemical, medical, high temperature gas filtration, scientific research, metallurgy, food, machinery and other industries. Its main filter material is 304, 304L, 316, 316L stainless steel fiber sintered felt and stainless steel woven mesh as the main filter medium, the sealing surfaces of the filter element are joined by argon arc welding process, and the filter layer adopts multi-fold folding process to form a complete filter element , No leakage, no medium shedding phenomenon, stainless steel fiber sintered felt is a porous depth filter material made of stainless steel fiber by high temperature sintering; stainless steel woven mesh is woven from stainless steel wire.

●Features:

1. The stainless steel precision filter element has high porosity, good air permeability, low resistance and low pressure difference;

2. After the stainless steel precision filter element is folded, the filtering area is large and the dirt holding capacity is large;

3. The stainless steel precision filter element is resistant to high temperature and corrosion, and is suitable for filtration of highly viscous liquids;

4. Good regeneration performance, can be used repeatedly after chemical cleaning, high temperature and ultrasonic cleaning;

5. All stainless steel structure, wide chemical compatibility;

●Main technical parameters

1. Maximum working temperature of stainless steel precision filter element: ≤500℃

2. Filtration precision: 1-200um

3. Working pressure: 0.1-30MPa

4. Filter element specifications: 5-40 inches (can be made separately according to user requirements)

5. Interface form: 222, 226, 215, M36, M28, M24, M22, M20 threaded interface, etc.