| Model: | X(S)M-110X(6-60 |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | Banbury Mixer , Rubber banbury mixer , mixer |

| Price: |

US $87000

/ Stand

|

| Min. Order: | 1 Stand |

Product Description

With TCU,rotor is plated with chrome.

Control system is adopted with PLCsystem

good sealing performance.

Rubber banbury mixer

1.1.Application of equipment:

The use of mixing and plasticating of rubber matericl,there are conyer belt,wedge belt,hose,abdichtprofil and so on.

1.2.The use of equipment envoriment maxium temperature at 40 degree,minium temperature at 5 degree.The hight maxium relative humidity at 95%.

1.3.Main technical parameters

Model:X(S)M-110X(6-60)

Total volume of mixing chamber /L: 108 (2-wings)

Working volume of mixing chamber/L: 81

Speed of rear rotor / R/Min 6-60

Speed ratio of rotors 1:1.15

Pressure of compressed air / Mpa 0.6~0.8

Consumption of compressed air/ M3/H ~60

Pressure of cooling water Mpa 0.3~0.4

Consumption of cooling water / M3/H ~35

Steam pressure /Mpa 0.5~0.8

Steam consumption M3/H 720

Driving motor power /KW 450

Dimension /MM 7800X2855X4392

Gross weight (Excluding main motor) ~24

Rotor:

Mixer device

Mixer device is the central part of internal mixer, plasticity and mixer of material is done in mixing chamber.

Internal mixer device main made up of side frame, mixing chamber, rotor and bearing and sealing device of rotor side of rotor. Cooling water and heating steam can pass through the inner of mixing chamber. It has good effective of heating exchange and long use time. Rotor is elliptical shape two wings rotor, the working side of rotor is insurfacing welding horniness alloy, the whole working side of rotor is hard plating, it has good hard wearing and smooth capacity; sealing device of side of rotor is external pressure.

Charging device

Charging device is made up of left/right side block, rear block, charging door, bearing of charging, ect. It installed on upper side of charging door of mixing chamber used for charging. Start/stop charging door is controlled by cylinder. There is a charging door security pin is installed in right side block of charging door in order to ensure safety. When repaired, charging is opening, insert security pin in charging door to fixed open ing position of charging door in order to prevent charging expected closed injuring people.

Pressure ram device

Pressure ram is made up of cylinder, piston, rod, pressure ram, ect. When pressure ram lift, it can be charging; after charging, dropped pressure ram to forcing to material used for strengthen rubber mixing. Pay more attention to: it must close charging door, pressure ram can only dropping. As following picture invention, secure pin of bottom of pressure ram stretch into mixing chamber through side frame and stock ring. It can be formed diagonal shape in through path of mixing chamber in order to prevent pressure ram abnormal dropping into mixing chamber destroying rotor. Secure pin has a distance with pressure ram and rotor. Attention: whenever internal miser in working or in repairing, secure pin must be on insert part.

Other model:

|

Model |

X(S)M-30X40 |

X(S)M-50X40 |

X(S)M-80X40 |

XMN-90X(6~60) |

X(S)M-110X40 |

X(S)M-110X(6~60) |

|

Model |

XM-160X30 |

XM-160X(4~40) |

XMN-190X(6~60) |

XM-250X20 |

XM-270X(4~40) |

XM-400X(6~60) |

| Payment Terms: | T/T |

|---|---|

Member Information

| Dalian HongXiang International Trade Co., Ltd. | |

|---|---|

| Country/Region: | Liao Ning - China |

| Business Nature: | Trading Company |

| Phone: | 0086-13464982387 |

| Contact: | Grace (Sale Manager) |

| Last Online: | 23 Dec, 2013 |

Related Products of this Company

-

Rubber Kneader

US $28600

-

Hopper-type hoist

US $10000

-

Rubber Refiner

US $30000

-

Tyre Machine

-

Rubber strainer

US $20000

-

Internal Mixer

US $215000

-

Rubber dispersion mixer (kneader)

US $20000

-

Rotary Curing Machine

US $77000

-

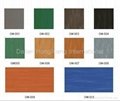

Rubber Flooring

US $10

-

Mixing Mill

US $13000