| Model: | PSZ2500 |

|---|---|

| Brand: | zhenyuan machinery |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | Crushing plant , Crusher station , Crushing system |

| Price: |

US $600000

/ unit

|

| Min. Order: | 1 unit |

Product Description

Xinxiang City Binhe Vibration No.1 Factory was established in 1964 . In the early summer of 2004,We registered trademark “ Zhenyuan” and rename Xinxiang City Zhenyuan Machinery Co .,Ltd .

As one of earliest factory do china coal crushing plant . We focus on coal mine equipment over 40 years, Our main products include: 2PLF grading teeth-roller crusher ,kinds of vibrating screen ,vibrating feeder, belt feeder(especially armored belt feeder is our patent products capacity can up to 4400t/h) and so on.

In a whole crusher station, usually you will use vibrating feeder→vibrating screen → crusher → vibrating screen → belt feeder. and other conveyor machines.

Now use coal mine as example:

Before the crusher ,usually we will install 1 unit armored belt feeder to make sure the mateial can be feeding crusher uniform. Same time ensure the effiency of crusher.

Because our crusher use grading design(details as the picture as follow) ,we can make sure more than 97% crushed material up to your requirements. So if you choose our crusher ,there will help you save vibrating screen cost.

1.Initially,the material is ripped by the leading faces of opposed rotor teeth.These subject the rock to multiple point loading ,in-ducing stress into the material to exploit any natural weaknesses.

2.At the second stage,material is broken in tension by being subjected to a three point loading, applied between the front tooth faces on one rotor,and rear tooth faces on the rotors.

3.Any lumps of material that still remain oversize,are broken as the rotors chop through the fixed teeth of the breaker bar,thereby achieving a three dimensional controlled product size.

Work ing Principle

Crusher station is set by received material, transport ,crushing and screening process equipment as whole plant. Through optimization of the process to make them have ideal work performance .Through the combination of different models build a large crushing and screen operation line to meet various processing work. Its advanced design, good performance, short construction period, high efficiency, easy operation and maintenance, low operation cost, work stable and reliable.

Structure & Feature

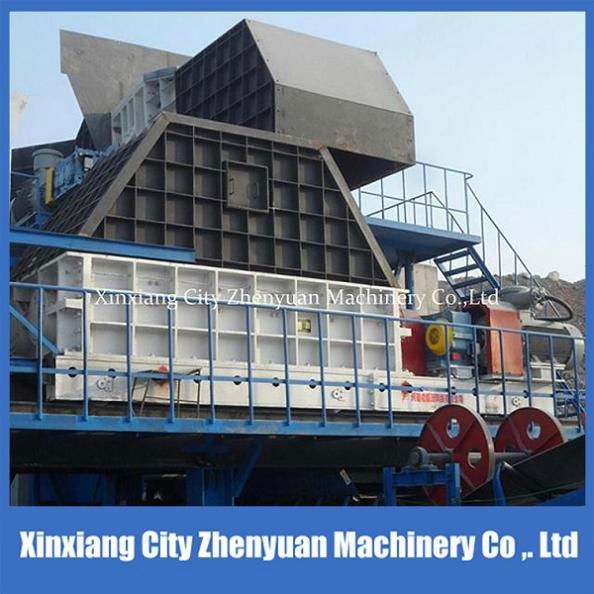

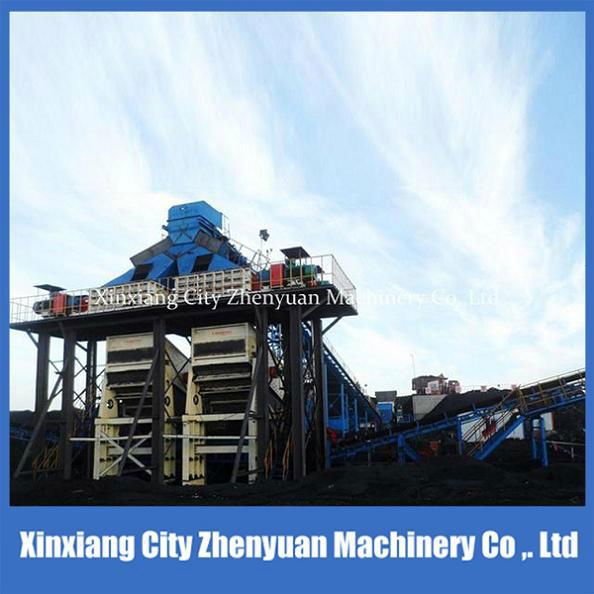

1.Crusher station is set by received material, transport, crushing ,screening and fast loading as one of the large mining crushing production system.

2.Crusher station includes heavy-duty continuous crusher station, large double teeth-roller crusher ,vibrating screen, fast loading buffer silo, box-type substation, complete electrical system, monitoring system, steel construe and other important equipments .The equipments is advanced technology, excellent quality.

3.Crusher station have diversification product particle size, compact structure, smooth operation, low cost, production, installation and commissioning cycle is short ,high mobility, civil and steel construction convenient advantages.

4.The core components of crusher station are all use international or domestic brands to ensure high reliability operation of the system .

5.Complete electrical system and monitoring system (infrared cameras, night vision conditions can be used), remote centralized operation and monitoring ,entire system uses PLC control, high degree of intelligence..

Application

To meet of large and medium size open pit mine material feeding, crushing ,screening and transport operations.

| Model | PSZ1200 | PSZ2000 | PSZ2500 | PSZ3000 | PSZ5000 | PSZ10000 |

Inlet size(mm) | ≤1500 | ≤1800 | ≤2000 | ≤2000 | ≤2000 | ≤2000 |

Output size (mm) | ≤300 | ≤300 | ≤300 | ≤350 | ≤350 | ≤400 |

Capacity(t/h) | 1200 | 1200 | 2500 | 3000 | 5000 | 10000 |

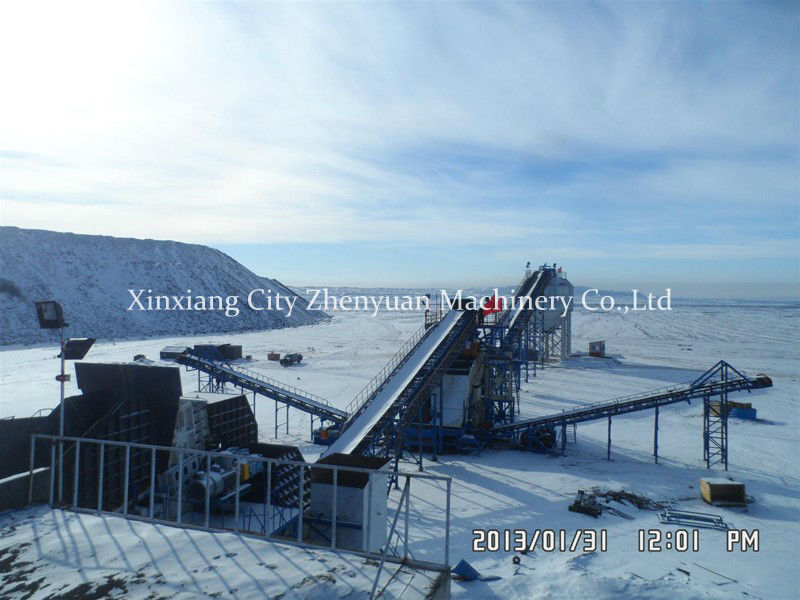

Coal Mine in Yiwu country of Xinjiang Guanghui Energy Co .,Ltd (Baishihu Open Pit Coal Mine)

2500t/h Semi-mobile continuous crushing and screening system equipments purchasing and installation work.

The basic process: raw coal storage and loading and unloading points ( storage capacity 200 cubic meters, bilateral 4 unloading bit)→Feeder ( Heave duty apron feeder )→First crusher→Belt conveyor→Second Crusher (2 units)→Vibrating screen ( 4units)→ Lump coal/Seed coal/ Powder coal belt conveyor→Finished product bunker→Loading

Xinjiang dacheng mine--1200t/h semi-mobile crusher station project (TPSZ-1200)

The basic process: raw coal storage and loading and unloading points ( storage capacity 100 cubic meters, bilateral 4 unloading bit)→First crusher→Second crusher→Belt conveyor→Vibrating screen→Powder coal belt conveyor→Storage bunker (storage capacity 2*300 t)→Loading

Shenhua group—1800t/h semi-mobile crusher station project (TPSZ-1800)

Choose Zhenyuan Crusher you will be able enjoy the following services:

1. Pre-sale services ----Act as a good adviser and assistant of clients; Enable them to returns on their investments.

2. Services during the sale ----Respect clients; Devote ourselves to improving the total value

3. After-sale services ----Provide considerate services to minimize clients' worries.

Warranty: 100% brand new when leaving the factory. The seller guarantee quality of the machines (excluding wearing parts)for a period of one year from the date of trial run finish under our technician's guidance, but not exceed 13 months from date on which machine leaves the factory.

Workshop of Zhenyuan:

We focus on Mining equipment more than 40 year.Choose Zhenyuan you will choose a professional technical team, to provide you the most professional equipment !

| Payment Terms: | T/T,L/C at sight |

|---|---|

Member Information

| Henan Zhenyuan Science & Technology Co.,Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 737323 |

| Contact: | Sarah Song (Sales Manager) |

| Last Online: | 17 May, 2013 |

Related Products of this Company

-

2 PLF Series Double Tooth Roller Coal

-

Vibrating Dewatering Sifter

US $100000

-

Cricular Vibrating Sizing Screens/Sizing

US $10000

-

coal screening equipment

-

Vibrating Dewatering Screen

US $1000000

-

Zhenyuan Built China Largest Crusher

US $600000