| Model: | A-12 |

|---|---|

| Brand: | spring seeding |

| Origin: | Made In China |

| Category: | Industrial Supplies / Environment Protection Facilities / Sewerage |

| Label: | Filter press filter , Press belt , Filter press filter |

| Price: |

¥12

/ pc

|

| Min. Order: | 20 pc |

Product Description

Hangzhou spring filtration technology limited company product performance: 1 filter with high tensile strength, folding resistance force is strong, the net surface monofilament uniform, have flexibility 2 filter belt joint glued joints excellent workmanship, the use of imported latex, thin, easy to fall off. Joint steel high strength, wear resistance. Uniform thin thickness at the interface, not easy injury scraper. The 3 filter belt on both sides of glue used for imported latex, soft, uniform, not easy to fall off. The 4 filter cake with smooth surface, easy to peel, with easy flushing filter.

Product parameter

Brand:

Spring

Model.

Varied

Texture of material.

PET

Type:

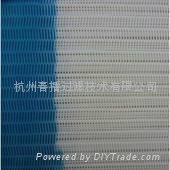

Braid

Applicable objects:

Products are widely used in the city sewage treatment plants, paper mills, printing and dyeing factory, chemical plants, electroplating factory, pharmaceutical factory, food factory, ceramics factory, mining and other industries of the sludge dewatering

Scope of application:

Products are widely used in the city sewage treatment plants, paper mills, printing and dyeing factory, chemical plants, electroplating factory, pharmaceutical factory, food factory, ceramics factory, mining and other industries of the sludge dewatering

Compilation:

Herringbone network

Specifications.

According to the requirement of production

For more information

Hangzhou spring filtration technology limited company product performance:

The 1 filter with high tensile strength, folding resistance force is strong, the net surface monofilament uniform, with flexibility

The 2 filter belt joint glued joints excellent workmanship, the use of imported latex, thin, easy to fall off. Joint steel high strength, wear resistance. Uniform thin thickness at the interface, not easy injury scraper.

The 3 filter belt on both sides of glue used for imported latex, soft, uniform, not easy to fall off.

The 4 filter cake with smooth surface, easy to peel, with easy flushing filter.

The 5 filter with the radial direction is not easy deformation, no arch, don't fold. Long service life with acid and alkali resistance, wear resistance, resistance to high temperature (120 ℃ in the environment in the long time operation) etc..

Belt filter performance: cake thickness, easy regeneration, the cake is easy to peel. Shape stability, no deformation, no deviation, do not hit fold, the tensile strength is big, strong resistance to acid and alkali. Can be high, low temperature. Good permeability. Products are widely used in the city sewage treatment plants, paper mills, printing and dyeing factory, chemical plants, electroplating factory, pharmaceutical factory, food factory, ceramics factory, mining and other industries of sludge dewatering.

Different specifications and dimensions can be OEM production, spring company can provide product selection, installation, commissioning the machine, all in one service. Customers to buy the rest assured that with the peace of mind. Spring company commitment: "preferential prices, high quality after sale service"

Filter press filter belt and fault analysis is easy to produce in the process of

A: the belt filter net belt running

1 material conveying capacity is too large

2 belt filter press speed too slow

3 materials the flocculation effect is not good

The 4 filter mesh belt cleaning is not clean

The 5 filter mesh belt tension is too large

6 press wedge improperly adjusted

7 belt type filter press filter with permeability from the inappropriate (too small)

Two: the material sticking belt filter mesh belt, stripping not net

The flocculation effect of material is not good

The 2 filter with the surface is too rough

3 cake too thin (with tachycardia induced)

The 4 doctor and dewatering filter gap inappropriate or scraper wear

5 dehydration belt do not wash clean

Three: filter net belt running deviation

The 1 bias adjustable device failure

2 cloth uneven, cause local material concentration

3 rollers that sticky material too much

The 4 one roller or roller axis is not parallel with

The 5 filter net with pleated

Four: the filter belt

The 1 overload

The 2 filter mesh belt tensioning force is not enough

3 rolls.

Five: the belt filter net with pleated

The 1 tension is too large or too large roller winding

2 dehydration net belt running deviation of serious fails to correct

The 3 one or more axes are not parallel to the roller

4 cloth material caused by uneven local concentration

5 roller material sticking too much not timely liquidation

The 6 upper and lower filter belt tension is not synchronized

The 7 upper and lower press belt walking without synchronization

Six: filter mesh belt joint fracture

1 material does not cause stress concentration

2 press network with short, no shrinkage space filled material, cause net belt tension gauge

The 3 overload

4 roller surface sticky material too much, resulting in stress concentration

The 5 blade wear, metal stent broken belt joint

Seven: the belt filter mesh belt damage or excessive wear

1 hard extrusion

2 flat feeding mechanism or unloading mechanism of metal stent in direct contact with the polyester dehydration net surface

3 press belt after pleating is not adjusted, resulting in local wear

4 roller is ineffective or not.

The 5 tension is too small, the roller does not rotate, mesh belt

6 press roll surface, local rubber stripping

Eight: the moisture of filter cake suddenly too much

1 flocculant effect is not good

The 2 filter with low density, is mainly the warp density

The 3 filter mesh belt do not wash clean

Nine: the belt filter belt on both sides of the elasticity is not a

1 cloth uneven

The 2 one or more axes are not parallel to the roller

The 3 part roller surface material sticking too much

Ten: the pressure mud network with no mud, sludge filled the gap, and the lower the air pressure filter dewatering, belt filter always slip

1 check the filter cloth and the filter net is damaged, if damaged please consider replacing.

Wastewater sludge 2 sludge source ingredients whether change - treatment might contain difficult dehydration material - can be "small" to test its dehydration.

3 now the pressure mud time before and whether there are differences, whether the change process.

The 4 filter mesh belt whether there is abnormal

5 the right to extend the filter press dewatering time, extend the compressed gas recoil time, prolong the residence time of stop after pressure filtration and mud.

| Payment Terms: | TT |

|---|---|

Member Information

| Hangzhou city spring Filtration Technology Co., Ltd. | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 15658015943 |

| Contact: | Wang Shuanghe (vice president) |

| Last Online: | 04 May, 2013 |