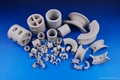

My company on the basis of the original inert ceramic ball, high temperature, high fever, high thermal shock resistance, high-quality refractory production Perforated ball, has good mechanical strength, high temperature resistance temperature of 1790 ° C (maximum), thermalshock resistance, acid and alkali chemical corrosion is particularly excellent, except hydrogen fluoride, the ability of all inorganic and organic acids and strong alkaline substances such as sodium hydroxide solution. The product also has the appropriate specific surface area and high porosity. Compared with ordinary inert ceramic ball,piled porosity increased by 6-10%, 15-25% increase in the specific surface area. Perforated ball than the larger the surface area, so that the efficiency of the contact reaction. Can reduce the weight of the bed, so that the purification and uniform distribution of the fluid in the reactor, the heat and mass transfer reaction uniformity, efficient, and does not make the reactants and the heat concentration, large numbers appear in the local areas. Opening porcelain higher the porosity can accommodate adsorption in various raw gas-liquid gum, coke powder, heavy metals and other solid particles of impurities to prevent during operation due to coke cause catalyst poisoning. the purpose of protect the catalyst. inert alumina Ciqiu in the reaction tower inside having a low pressure drop, reducing the resistance of the tower, to improve the mass transfer efficiency of the entire reaction tower, and has an important role to improve the yield, improve product quality. Suitable the inert alumina openings ceramic ball in the coal chemical hydrogen production, gas purification, the period of synthetic ammonia, Sec conversion furnace, deep processing of crude oil, catalytic reforming, hydrogen production, hydrotreating, catalytic cracking proppant or protection as a catalyst the high-temperature high-pressure environment of the agent used.