| Model: | 1 |

|---|---|

| Brand: | Jutai Special Steel Pipe Co.,Ltd. |

| Origin: | Made In China |

| Category: | Construction & Decoration / Pipe, Tube & Parts / Steel Pipe & Tube |

| Label: | Pipe , tube , stainless |

| Price: |

US $1

/ pc

|

| Min. Order: | 1 pc |

Product Description

US Standard

ASTM A269/A269M, ASME SA269/SA269M Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM A312/A312M, ASME SA312/SA312M Specification for Seamless and Welded Austenitic Stainless Steel Pipes n for General Requirements for Specialized Carbon and Alloy Steel Pipe

EN Standards

EN 10216-5 Welded Stainless Steel Tube

JIS-Standards

JIS G 3447 Stainless Steel Sanitary Pipes

G 3448 Light Gauge Stainless Steel Tubes for Ordinary Piping

G 3459 Stainless Steel Pipes

G 3468 Large Diameter Welded Stainless Steel Pipes

G 3463 Stainless Steel Boiler and Heat Exchanger Tubes

G 3446 Stainless Steel Pipes for Machine and Structural Purposes

Mil T Standards:

Mil T 8606,

Mil T 8808 Type 2

Mil T 6845 Type 2

Our Tube Manufacturing Services Include:

· In-house comprehensive testing and inspection.

· Ink Jet product marking

· Tubes cut to length from 25mm to 20 metre

· Tube calibration

· Inline eddy current testing

· Tube polishing

· Dull, satin, bright, super mirror

· Annealing & black oxidizing

· Coiled tubes in 100m - 250m coils fully annealed.

Tube Types

All of the tubing we produce begins its life as a welded tube. From there, we can do additional processing to the tube to reduce or essentially eliminate any evidence of a weld seam, or to achieve other goals such as very tight and consistent tolerances. Our welded and drawn over mandrel tubing is nearly indistinguishable from seamless tubing, and is often used as a less expensive substitute for it. Our five types of tubing are:

•As Welded

•Outer Diameter Conditioned

•Bead Hammered

•Cold Drawn Outer Diameter

•Welded & Drawn Over Mandrel

Each type of tube undergoes different production processes that impact the dimensions and tolerances of a tube's cross section. The size ranges and tolerances available for each tube type are described in detail on the sizes page. Important dimensional terms discussed below include the O.D. (or Outer Diameter), the I.D. (or Interior Diameter), and the Wall Thickness.

As Welded tubing

As Welded tubing is our least expensive product line, and is manufactured by running coils of annealed strip through a cold roll forming process. It is continuously welded using appropriate shielding gases for each alloy to prevent oxidation of the seam. With As Welded tubing, the seam is clearly visible on both the exterior and interior of the tube, but the size of the weld bead is held within strict tolerances.

Typical applications for As Welded tubing include tubular heating elements for both industrial and consumer targeted end products, beverage or fluid transportation systems, mechanical devices, automotive applications, and heat exchange devices.

Outer Diameter Conditioned tubing

OD Conditioned tubing is the first step-up from As Welded tubing. After its initial forming process, which is identical to the process used to create As Welded tubing, OD Conditioned tubing is then run through a process which rounds and blends the exterior weld seam so that it is flush with the exterior of the tube. As a result, it is difficult to see the weld seam on the exterior of an OD Conditioned tube with the naked eye. However, the interior of the tube is not affected and is therefore identical to that of an As Welded tube, and the weld seam remains visible.

OD Conditioned tubing is beneficial when compression fittings, flare fittings, or O-ring seals are used, as the smoother OD surface reduces potential leak paths.

Bead Hammered tubing

Bead Hammered tubing is initially formed with a process identical to that of As Welded tubing, except that an additional, special cold roll forming process with an interior mandrel support is added to smooth both the interior and exterior weld seam. As a result, the seam is nearly invisible on both the exterior and the interior, creating a tube that is an excellent, lower cost substitute for seamless tubing.

Applications for Bead Hammered tubing include anything where interior and exterior smoothness are important, such as certain liquid and gas handling applications, and fabricated applications where exterior fittings require a smooth surface.

Cold Drawn Outer Diameter tubing

CDOD tubing is created by running As Welded tubing through a cold drawing process using a die that is slightly smaller than the starting tube diameter. No interior mandrel support is used for CDOD tubing. The result is a tube with no visible exterior weld seam and which can hold tighter tolerances than As Welded, OD Conditioned, or Bead Hammered tubing. In addition, as is the case with Welded and Drawn over Mandrel tubing, any OD size tube can be created starting at 0.125 inches up to 1.245 inches in increments of 0.001 inch without requiring an extra charge for special tooling.

Applications for CDOD tubing include anything where exterior smoothness and tight tolerances are important, such as certain liquid and gas handling applications, and fabricated applications where exterior fittings require a smooth surface, as well as small orders for unique, non-standard OD sizes where an investment in special tooling is not practical.

Welded and Drawn Over Mandrel tubing

Welded and Drawn tubing is initially formed and welded using the same process as As Welded tubing, except that after it is initially formed it is then run through a drawing process similar to that used to form seamless tubing. The difference from CDOD tubing is that with Welded and Drawn tubing , a mandrel is inserted into the tube to ensure that the interior diameter can be held to a very tight tolerance, and the tube is passed through a die that reduces the outer diameter of the tube and compresses the interior diameter down to the size of the mandrel. This cold drawing process completely eliminates any evidence of the weld seam both internally and extermally. In addition, the process breaks up the cast grain structure of the weld zone, which gives the tube strength and burst pressure ratings equivalent to seamless tube while keeping the cost lower than the cost of seamless tubing. In addition, virtually any size of interior or exterior diameter can be created in increments of 0.001 inch, with very tight tolerances.

Welded and Drawn tubing is ideal where maximum strength or corrosion resistance is required, or where special temper characteristics, unique sizes, or very tight exterior and interior diamter tolerances are required.

Tube Finishes

Offers a variety of finishing options including annealing, stenciling, bead rolling, deburring, coiling, and polishing. We can provide either standard or score and break cut styles, and also can provide a variety of packaging options suitable for domestic or international shipping. We specialized in unique, made-to-order tubing and can custom engineer a solution for virtually any application.

Annealing

We is proud to offer full soak, bright annealing as an option for any of its tubing products. Full soak bright annealing provides the softest possible tubing suitable for the most challenging bending applications. Our bright anneal also leaves a finish that is as shiny as possible, which is critical for many applications.

Coiling

As Welded tubing (either annealed or unannealed) can be provided in coils of up to 500 feet.

Product Types:Stainless Steel Pipe, Stainless Steel Hollow Sections, Flat-Oval Tubes - Elliptical Tubes - Triangular Tubes, Ornamental Pipes and Hollow Sections, Annealed Pipes, Automotive Pipes, Evaporator and Heat Exchanger Pipes, Industrial Kitchen Pipes and Hollow Sections

| Austenitic Steels

EN 1.4301 - TP304 EN 1.4571 - TP316TI EN 1.4828 - TP309 EN 1.4311 - TP304LN EN 1.4845 - TP310S EN 1.4307 - TP304L EN 1.4432 - TP316L EN 1.4306 - TP304L EN 1.4404 - TP316L EN 1.4438 - TP317L EN 1.4401 - TP316 EN 1.4436 - TP316 EN 1.4541 - TP321 EN 1.4435 - TP316L EN 1.4833 - TP309S |

Superferritic and Superaustenitic Steels AL 29-4C® - UNS S44735 UNS N08367 EN 1.4547 - 254SMO EN 1.4529 - 1925HMO® EN 1.4565 - S34565 EN 1.4539 - TP904L

Duplex Steels EN 1.4162 - LDX 2101® EN 1.4362 - S32304 EN 1.4410 - S32750 EN 1.4462 - S31803 |

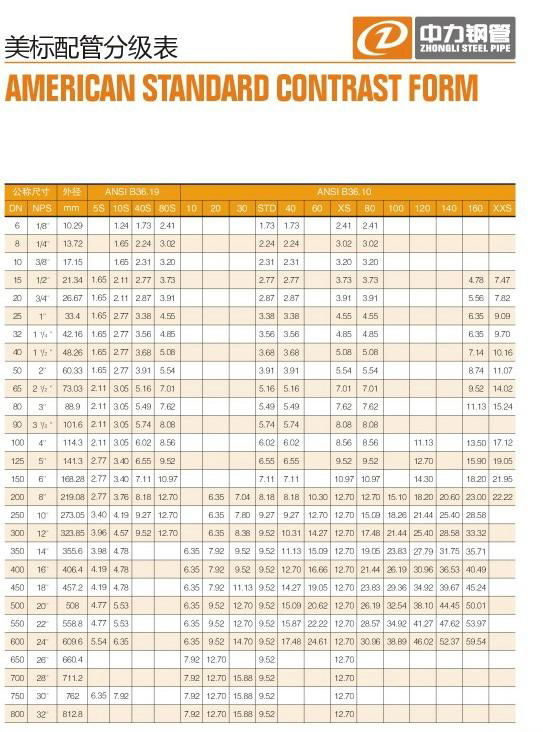

O.D. W/T Weight

inch mm. Sch. mm. inch. Kg/m. Lb/ft.

1/8" 10.3 10S 1.24 0.049 0.28 0.19

1/8" 10.3 STD-40 1.73 0.068 0.37 0.25

1/8" 10.3 XS-80 2.41 0.095 0.48 0.32

1/4" 13.7 10S 1.65 0.065 0.50 0.34

1/4" 13.7 STD-40 2.24 0.088 0.64 0.43

1/4" 13.7 XS-80 3.02 0.119 0.81 0.55

3/8" 17.1 10S 1.65 0.065 0.64 0.43

3/8" 17.1 STD-40 2.31 0.091 0.85 0.57

3/8" 17.1 XS-80 3.20 0.126 1.11 0.75

1/2" 21.3 5S 1.05 0.042 0.53 0.36

1/2" 21.3 10S 2.11 0.083 1.01 0.68

1/2" 21.3 STD-40 2.77 0.109 1.28 0.86

1/2" 21.3 XS-80 3.73 0.147 1.63 1.10

1/2" 21.3 160 4.78 0.188 1.97 1.33

1/2" 21.3 XXS 7.47 0.294 2.57 1.73

3/4" 26.7 5S 1.65 0.065 1.03 0.69

3/4" 26.7 10S 2.11 0.083 1.29 0.87

3/4" 26.7 STD-40 2.87 0.113 1.70 1.14

3/4" 26.7 XS-80 3.91 0.154 2.22 1.49

3/4" 26.7 160 5.56 0.219 2.93 1.97

3/4" 26.7 XXS 7.82 0.308 3.68 2.48

1" 33.4 5S 1.65 0.065 1.31 0.88

1" 33.4 10S 2.77 0.109 2.12 1.42

1" 33.4 STD-40 3.38 0.133 2.53 1.70

1" 33.4 XS-80 4.55 0.179 3.27 2.18

1" 33.4 160 6.35 0.250 4.28 2.88

1" 33.4 XXS 9.09 0.358 5.51 3.71

1 1/4" 42.2 5S 1.65 0.065 1.67 1.12

1 1/4" 42.2 10S 2.77 0.109 2.72 1.83

1 1/4" 42.2 STD-40 3.56 0.140 3.43 2.31

1 1/4" 42.2 XS-80 4.85 0.191 4.51 3.03

1 1/4" 42.2 160 6.35 0.250 5.67 3.81

1 1/4" 42.2 XXS 9.70 0.382 7.85 5.28

1 1/2" 48.3 5S 1.65 0.065 1.92 1.29

1 1/2" 48.3 10S 2.77 0.109 3.14 2.11

1 1/2" 48.3 STD-40 3.68 0.145 4.09 2.75

1 1/2" 48.3 XS-80 5.08 0.200 5.47 3.68

1 1/2" 48.3 160 7.14 0.281 7.32 4.92

1 1/2" 48.3 XXS 10.15 0.400 9.65 6.49

2" 60.3 5S 1.65 0.065 2.41 1.62

2" 60.3 2.11 0.083 3.06 2.06

2" 60.3 10S 2.77 0.109 3.97 2.67

2" 60.3 3.18 0.125 4.52 3.04

2" 60.3 STD-40 3.91 0.154 5.49 3.69

2" 60.3 XS-80 5.54 0.218 7.56 5.08

2" 60.3 160 8.74 0.344 11.23 7.55

2" 60.3 XXS 11.07 0.436 13.58 9.13

2 1/2" 73.0 5S 2.11 0.083 3.73 2.51

2 1/2" 73.0 10S 3.05 0.120 5.32 3.57

2 1/2" 73.0 30 4.78 0.188 8.12 5.46

2 1/2" 73.0 STD-40 5.16 0.203 8.72 5.86

2 1/2" 73.0 XS-80 7.01 0.276 11.52 7.74

2 1/2" 73.0 160 9.53 0.375 15.08 10.14

2 1/2" 73.0 XXS 14.02 0.552 20.60 13.84

3" 88.9 5S 2.11 0.083 4.56 3.07

3" 88.9 2.77 0.109 5.95 4.00

3" 88.9 10S 3.05 0.120 6.52 4.38

3" 88.9 3.18 0.125 6.79 4.56

3" 88.9 3.58 0.141 7.61 5.12

3" 88.9 3.96 0.156 8.38 5.63

3" 88.9 STD-40 5.49 0.216 11.41 7.67

3" 88.9 XS-80 7.62 0.300 15.43 10.37

3" 88.9 160 11.13 0.438 21.56 14.49

3" 88.9 XXS 15.24 0.600 27.96 18.79

3 1/2" 101.6 5S 2.11 0.083 5.23 3.52

3 1/2" 101.6 10S 3.05 0.120 7.49 5.03

3 1/2" 101.6 30 4.78 0.188 11.53 7.75

3 1/2" 101.6 STD-40 5.74 0.226 13.71 9.21

3 1/2" 101.6 XS-80 8.08 0.318 18.83 12.65

4" 114.3 5S 2.11 0.083 5.90 3.97

4" 114.3 10S 3.05 0.120 8.46 5.68

4" 114.3 3.18 0.125 8.81 5.92

4" 114.3 3.96 0.156 10.89 7.32

4" 114.3 4.37 0.172 11.97 8.05

4" 114.3 4.78 0.188 13.04 8.76

4" 114.3 5.16 0.203 14.03 9.43

4" 114.3 5.56 0.219 15.06 10.62

4" 114.3 STD-40 6.02 0.237 16.24 10.91

4" 114.3 6.35 0.250 17.08 11.48

4" 114.3 7.14 0.281 19.06 12.81

4" 114.3 7.92 0.312 20.99 14.11

4" 114.3 XS-80 8.56 0.337 22.55 15.15

4" 114.3 120 11.13 0.438 28.61 19.23

4" 114.3 160 13.49 0.531 33.88 22.77

4" 114.3 XXS 17.12 0.674 41.45 27.85

5" 141.3 3.96 0.156 13.55 9.11

5" 141.3 4.78 0.188 16.26 10.93

5" 141.3 5.56 0.219 18.80 12.63

5" 141.3 STD-40 6.55 0.258 21.99 14.78

5" 141.3 7.14 0.281 23.86 16.04

5" 141.3 7.92 0.312 26.32 17.69

5" 141.3 XS-80 9.53 0.375 31.28 21.02

5" 141.3 120 12.70 0.500 40.69 27.34

5" 141.3 160 15.88 0.625 49.62 33.34

5" 141.3 XXS 19.05 0.750 58.01 38.98

6" 168.3 4.37 0.172 17.84 11.99

6" 168.3 4.78 0.188 19.47 13.09

6" 168.3 5.16 0.203 20.97 14.09

6" 168.3 5.56 0.219 22.54 15.15

6" 168.3 6.35 0.250 25.62 17.22

6" 168.3 STD-40 7.11 0.280 28.55 19.19

6" 168.3 7.92 0.312 31.64 21.26

6" 168.3 8.74 0.344 34.74 23.35

6" 168.3 9.53 0.375 37.69 25.33

6" 168.3 XS-80 10.97 0.432 42.99 28.89

6" 168.3 12.70 0.500 49.23 33.08

6" 168.3 120 14.27 0.562 54.75 36.79

6" 168.3 15.88 0.625 60.30 40.52

6" 168.3 160 18.26 0.719 68.25 45.86

6" 168.3 19.05 0.750 70.85 47.61

6" 168.3 XXS 21.95 0.864 80.02 53.77

6" 168.3 22.23 0.875 80.87 54.34

8" 219.1 4.78 0.188 25.52 17.15

8" 219.1 5.16 0.203 27.50 18.48

8" 219.1 5.56 0.219 29.58 19.88

8" 219.1 20 6.35 0.250 33.65 22.61

8" 219.1 30 7.04 0.277 37.19 24.99

8" 219.1 7.92 0.312 41.66 28.00

8" 219.1 STD-40 8.18 0.322 42.98 28.88

8" 219.1 8.74 0.344 45.80 30.78

8" 219.1 9.53 0.375 49.75 33.43

8" 219.1 60 10.31 0.406 53.62 36.03

8" 219.1 11.13 0.438 57.66 38.75

8" 219.1 XS-80 12.70 0.500 65.30 43.88

8" 219.1 14.27 0.562 72.81 48.93

8" 219.1 100 15.09 0.594 76.69 51.53

8" 219.1 15.88 0.625 80.31 54.02

8" 219.1 120 18.26 0.719 91.36 61.39

8" 219.1 19.05 0.750 94.93 63.79

8" 219.1 140 20.62 0.812 101.95 68.51

8" 219.1 XXS 22.23 0.875 108.96 73.22

8" 219.1 160 23.01 0.906 112.40 75.59

8" 219.1 25.40 1.000 122.56 82.36

10" 273.0 4.78 0.188 31.94 21.46

10" 273.0 5.16 0.203 34.43 23.14

10" 273.0 5.56 0.219 37.04 24.89

10" 273.0 20 6.35 0.250 42.18 28.34

10" 273.0 7.09 0.279 46.97 31.56

10" 273.0 30 7.80 0.307 51.53 34.63

10" 273.0 8.74 0.344 57.34 38.66

10" 273.0 STD-40 9.27 0.365 60.90 40.92

10" 273.0 11.13 0.438 72.61 48.79

10" 273.0 XS-60 12.70 0.500 82.35 55.34

10" 273.0 14.27 0.562 91.92 61.80

10" 273.0 80 15.09 0.594 96.95 65.15

10" 273.0 15.88 0.625 101.71 68.35

10" 273.0 100 18.26 0.719 115.87 77.86

10" 273.0 20.62 0.812 129.64 87.11

10" 273.0 120 21.44 0.844 134.35 90.28

10" 273.0 22.23 0.875 138.87 93.32

10" 273.0 23.83 0.938 147.91 99.39

10" 273.0 XXS-140 25.40 1.000 156.66 105.22

10" 273.0 160 28.58 1.125 174.01 116.93

10" 273.0 31.75 1.250 190.81 128.22

12" 323.8 20 6.35 0.250 50.22 33.75

12" 323.8 7.14 0.281 56.32 37.85

12" 323.8 7.92 0.312 62.32 41.88

12" 323.8 30 8.38 0.330 65.85 44.23

12" 323.8 8.74 0.344 68.60 46.10

12" 323.8 STD 9.53 0.375 74.61 50.13

12" 323.8 40 10.31 0.406 80.51 54.10

12" 323.8 11.13 0.438 86.69 58.25

12" 323.8 XS 12.70 0.500 98.42 66.14

12" 323.8 60 14.27 0.562 110.03 73.94

12" 323.8 15.88 0.625 121.81 81.85

12" 323.8 80 17.48 0.688 133.38 89.63

12" 323.8 19.05 0.750 14.62 97.18

12" 323.8 20.62 0.812 155.73 104.65

12" 323.8 100 21.44 0.844 161.48 108.51

12" 323.8 23.83 0.938 178.07 119.65

12" 323.8 XXS-120 25.40 1.000 188.80 126.87

12" 323.8 26.97 1.062 199.42 134.00

12" 323.8 140 28.58 1.125 210.18 141.23

12" 323.8 31.75 1.250 230.98 155.21

12" 323.8 160 33.32 1.312 241.10 162.01

14" 355.6 10 6.35 0.250 55.25 37.13

14" 355.6 20 7.92 0.312 68.60 46.1

14" 355.6 8.74 0.344 75.52 50.75

14" 355.6 STD-30 9.53 0.375 82.16 55.21

14" 355.6 10.31 0.406 88.68 59.59

14" 355.6 40 11.13 0.438 95.51 64.18

14" 355.6 XS 12.70 0.500 108.48 72.90

14" 355.6 14.27 0.562 121.33 81.53

14" 355.6 60 15.09 0.594 128.00 86.01

14" 355.6 80 19.05 0.750 159.71 107.32

14" 355.6 100 23.83 0.938 196.94 132.34

14" 355.6 25.40 1.000 208.92 140.39

14" 355.6 26.97 1.062 220.78 148.36

14" 355.6 120 27.79 1.094 226.93 152.49

14" 355.6 140 31.75 1.250 256.13 172.11

14" 355.6 160 35.71 1.406 284.56 191.21

16" 406.4 10 6.35 0.250 63.28 42.52

16" 406.4 7.14 0.281 71.01 47.72

16" 406.4 20 7.92 0.312 78.62 52.83

16" 406.4 8.74 0.344 86.58 58.18

16" 406.4 STD-30 9.53 0.357 94.21 63.31

16" 406.4 10.31 0.406 101.72 68.36

16" 406.4 11.13 0.438 109.59 73.64

16" 406.4 XS-40 12.700.500 124.55 83.69

16" 406.4 14.27 0.562 139.39 93.67

16" 406.4 15.88 0.625 154.48 103.80

16" 406.4 60 16.66 0.656 161.74 108.69

16" 406.4 17.48 0.688 169.35 113.80

16" 406.4 19.05 0.750 183.81 123.52

16" 406.4 20.62 0.812 198.15 133.15

16" 406.4 80 21.44 0.844 205.60 138.15

16" 406.4 25.40 1.000 241.06 161.98

16" 406.4 100 26.19 1.031 248.05 166.68

16" 406.4 120 30.96 1.219 289.54 194.56

16" 406.4 31.75 1.250 296.31 199.11

16" 406.4 140 36.53 1.438 336.57 226.16

16" 406.4 160 40.49 1.594 369.06 247.99

18" 457 20 7.92 0.312 88.60 59.54

18" 457 8.74 0.344 97.59 65.58

18" 457 STD 9.53 0.375 106.23 71.38

18" 457 10.31 0.406 114.72 77.09

18" 457 30 11.13 0.438 123.62 83.07

18" 457 XS 12.70 0.500 140.56 94.45

18" 457 40 14.27 0.562 157.38 105.75

18" 457 15.88 0.625 174.50 117.25

18" 457 17.48 0.688 191.38 128.60

18" 457 60 19.05 0.750 207.82 139.65

18" 457 80 23.83 0.938 257.13 172.78

18" 457 25.40 1.000 273.08 183.50

18" 457 26.97 1.062 288.91 194.14

18" 457 28.58 1.125 305.01 204.96

18" 457 100 29.36 1.156 312.76 210.16

18" 457 30.18 1.188 320.88 215.62

18" 457 31.75 1.250 336.33 226.00

18" 457 120 34.93 1.375 367.25 246.78

18" 457 140 39.67 1.562 412.40 277.12

18" 457 160 45.24 1.781 464.03 311.81

20" 508 8.74 0.344 108.70 73.04

20" 508 STD-20 9.53 0.375 118.33 79.51

20" 508 10.31 0.406 127.82 85.89

20" 508 11.13 0.438 137.76 92.57

20" 508 XS-30 12.70 0.500 156.70 105.3

20" 508 14.27 0.562 175.51 117.94

20" 508 40 15.09 0.594 185.28 124.50

20" 508 15.88 0.625 194.67 130.81

20" 508 17.48 0.688 213.59 143.53

20" 508 19.05 0.750 232.03 155.92

20" 508 60 20.62 0.812 250.34 168.22

20" 508 25.40 1.000 305.35 205.18

20" 508 80 26.19 1.031 314.33 211.22

20" 508 30.18 1.188 359.22 241.38

20" 508 31.75 1.250 376.66 253.10

20" 508 100 32.54 1.281 385.40 258.97

20" 508 120 38.10 1.500 445.97 299.67

20" 508 140 44.45 1.750 513.27 344.90

20" 508 160 50.01 1.969 570.54 383.38

22" 559 8.74 0.344 119.80 80.5

22" 559 STD-20 9.53 0.375 130.44 87.65

22" 559 XS-30 12.70 0.500 172.83 116.14

22" 559 15.88 0.625 214.84 144.37

22" 559 17.48 0.688 235.79 158.44

22" 559 19.05 0.750 256.23 172.18

22" 559 20.62 0.812 276.54 185.83

24" 610 8.74 0.344 130.90 87.96

24" 610 STD-20 9.53 0.375 142.55 95.79

24" 610 XS 12.70 0.500 188.96 126.98

24" 610 30 14.27 0.562 211.76 142.30

24" 610 15.88 0.625 233.02 157.93

24" 610 40 17.48 0.688 258.00 173.37

26 660 0.219-0.625

28 711 0.219-0.625

30 762 0.219-0.625

32 813 0.250-0.751

34 864 0.250-0.751

36 914 0.250-0.751

38 965 0.250-0.751

40 1016 0.250-0.751

42 1067 0.250-0.751

44 1118 0.250-0.751

46 1168 0.250-0.751

48 1219 0.250-0.751

52 1321 0.250-0.751

56 1422 0.250-0.751

60 1524 0.250-0.751

64 1626 0.365-0.851

68 1727 0.365-0.866

72 1829 0.365-0.866

76 1930 0.365-0.866

80 2032 0.365-0.866

84 2220 0.365-0.866

95 2420 0.365-0.866

100 2620 0.365-0.866

115 2820 0.365-0.866

| Price Terms: | CFR,CIF,FOB,T/T,L/C,etc |

|---|---|

| Embed HTML Code: | Seamless Stainless Steel Tubes |

Member Information

| JUTAI SPECIAL STEEL CO.,LTD. | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 18217541002 |

| Contact: | Tom.Tang (Sales Engineer ) |

| Last Online: | 22 Sep, 2015 |