Detailed Product Description

1.General Description

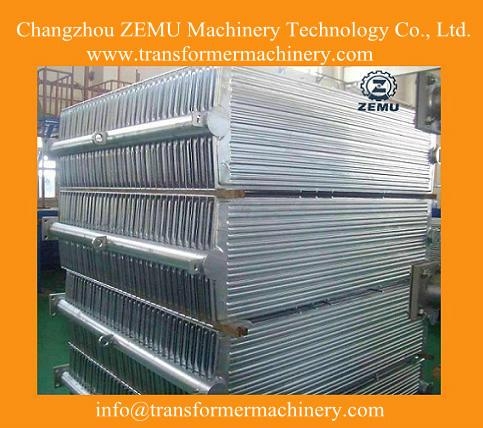

This radiator steel plate rolling forming machine is specially designed for producing Radiator for Transformer.

2.Parts of This Radiator Steel Plate Rolling Forming Machine

1) Hydraulic Automatic Decoiler

2) Transformer Radiator Fin Rolling Forming Machine

3) Hydraulic Automatic Plate Shears

4) Hydraulic Molding Machine

5) Hydraulic Station

6) PLC control System

3.Features of This Radiator Steel Plate Rolling Forming Machine

1) We manufacture Radiator Steel Plate for all type of transformer, such as 230, 375, 520mm wide and various lengths of Cragged

Type Panel Radiator. Being in the power industry for a long time, we bring in our technical expertise in manufacturing panel radiators.

2) Radiators are essential to cool the transformer to avoid rapid electrical performance

degradation especially at higher temperature. The radiators are manufactured taking into

account the various factors that affect the thermal performance of them. The width, length

and height of the radiator that affects the performance by affecting the heat transfer area

are carefully designed depending on the capacity of the transformers for whey are used.

The plates used in panel radiators are formed from cold rolled steel to maximize the prime heat transfer surface.

3) As an optional, the exterior surface treatment of panel radiator could be heat galvanization or heat galvanization plus spraying. With

the in-house testing facility we

make sure every radiator is pressure tested using compressed air and 100% leak proof.

Consistency being our strength, we promise our customers nothing less than the best,

always.

4.Production Process of This Radiator Steel Plate Rolling Forming Machine

Coil loading- Automatic decoiling -Rolling-Hydraulic forming - Automatic chip combination -Multi-Bilateral rolling cut-head cutting -final radiator chip

5.Note

We can provide any other machines for transformer making, like corrugated radiator Tank forming & welding machine, silicon steel

slitting & cut-to-length line, silicon steel core, slitting & cut-to-length line, silicon steel core assembling machine, coil winding machine, vacuum drying machine, oil filtering machine, etc..

6.Technical Data of This Radiator Steel Plate Rolling Forming Machine

1) Thickness of plate: 0.5~1.5mm

2) Rolling Forming Speed: 5~8m/min

3) Length of Plate: 400~3000mm

4) Total Power: 16.5KW

5) Rated Pressure: 10MPa

6) Users: Transformer Manufacturing Industry

7) Rated Voltage: 380V

8) Warranty Period: Twelve Months