| Model: | - |

|---|---|

| Brand: | BS |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Piping Tubing |

| Label: | KL fin tube , KL fin pipe , fin pipe |

| Price: |

-

|

| Min. Order: | 1 ton |

Product Description

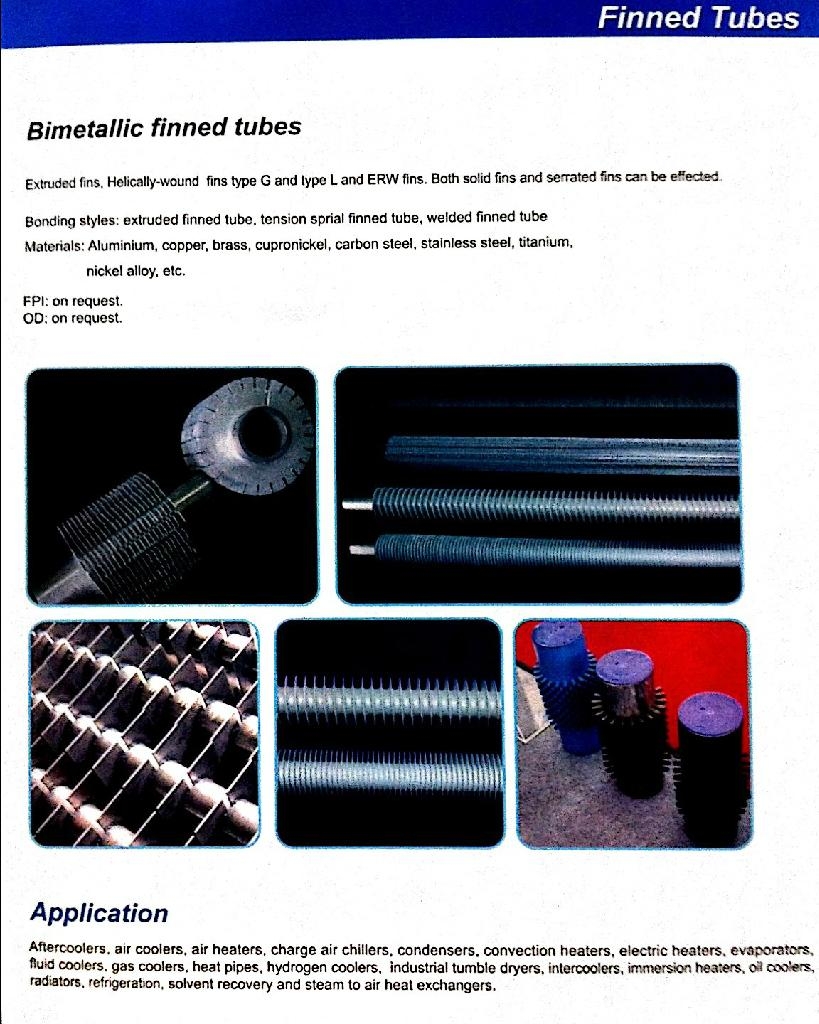

KL-type Fin Tube

Fin Materials::Aluminum, Copper

Tube Materials::Core Tube,Carbon steels (ASTM A 179/ A 214, St 35.8,ect.), low-alloy steels, stainless steels, copper-nickel alloys, aluminium bronze, copper, nickel-alloys (Alloy 400, ext.)

Fin Thickness::Min: 300 µ Max: 800µ

Tube Size::12.70mm~50.8mm

Fin Size::7~11.5Fins/Inch Fin Height Max 16mmH

Tube Materials::Core Tube,Carbon steels (ASTM A 179/ A 214, St 35.8,ect.), low-alloy steels, stainless steels, copper-nickel alloys, aluminium bronze, copper, nickel-alloys (Alloy 400, ext.)

Fin Thickness::Min: 300 µ Max: 800µ

Tube Size::12.70mm~50.8mm

Fin Size::7~11.5Fins/Inch Fin Height Max 16mmH

This type of fin has a knurled L shape base and is fixed by pressure on the tube.

- Fin Materials: Aluminum, Copper

- Tube Materials: No limits

- Fin Thickness: Min: 300 µ Max: 800µ

- MATERIAL COMBINATIONS

Core Tube

Carbon steels (ASTM A 179/ A 214, St 35.8,ect.), low-alloy steels, stainless steels, copper-nickel alloys, aluminium bronze, copper, nickel-alloys (Alloy 400, ext.), bimetal

Fins: Aluminium ASTM B209 Al 1060; ASTM B209 Al 1100

FIELDS OF APPLICATION

. the petroleum, chemical and petrochemical process industries

. natural gas treatment

. the steel industry: blast furnace and converter systems

. power generation: steam turbine exhaust condensing

- contact condensing with cooling of circulating condensate

- fossil and nuclear power plants

. air conditioning (freon, ammonia, propane)

. incineration of household refuse

. compressor coolers, ect.

MANUFACTURING PROCESS

The manufacturing strip is folded to from an L shape and then wound around the base tube. The feet of the fins are joined together and cover the whole of the finned surface. Both lends are clamped down to avoid unrolling through damage.

ADVANTAGES

Economic This method of manufacturing enables us to place the finning on a very thin-walled tube with is particularly desirable when using noble alloys (titanium, stainless, copper, nickel).

The tube can withstand a temperature of up to 130°C without the risk of atmospheric corrosion or thermal stress. L1 max. = 12 000 mm Fin Thickness = 0,3 - 0,4 mm Fa = Outer Tube Surface Area incl. Surface Area of Fins L2 max. = L1 -2t x = acc. to clients specification Fi = Interior Tube Surface Area per Meter (m2/m) FZR = Uncovered Tube Area between the fins

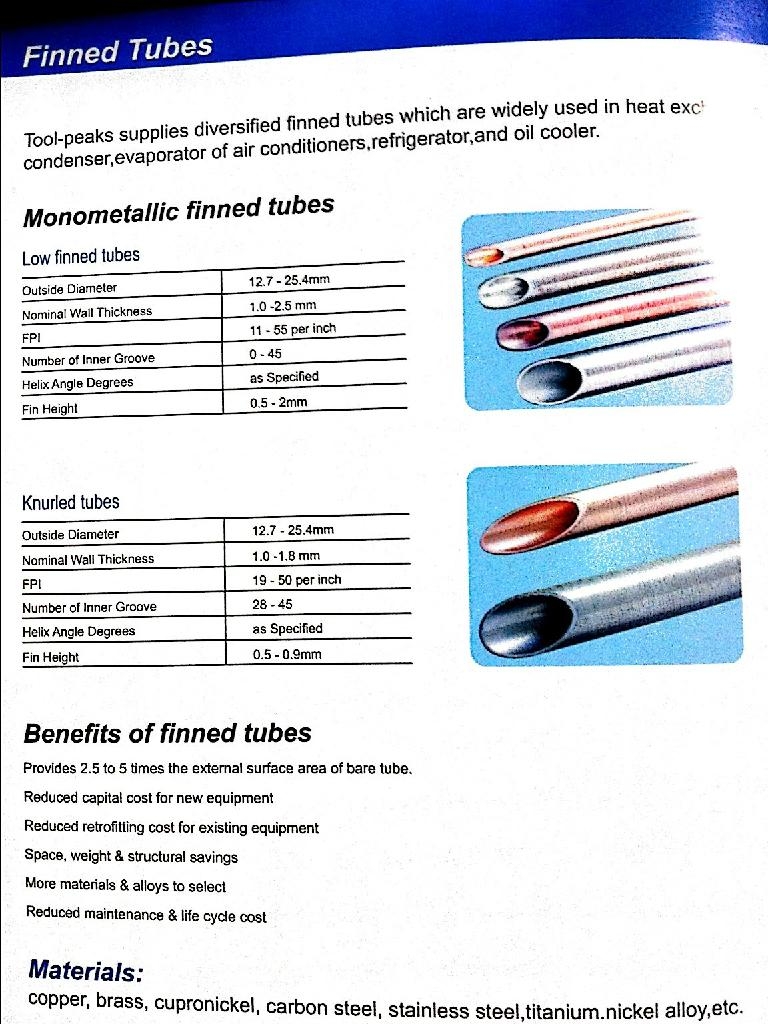

PRODUCTDESCRIPTIONTUBE MATERIALFIN MATERIALTUBE SIZEFIN SIZEHigh Fin TubeExtruded Fin TubeAll Kind of Material can be appliedAluminum A1050, A606115.88~50.87~11.5Fins/InchFin Height Max 16mmHL-Fin Tube(Wrap On Type)All Kind of Material can be appliedCopper C1100, C122012.70~50.87~11.5Fins/InchFin Height Max 16mmHG-Fin Tube (Imbedded Type)Aluminum A1100, A1050, A1060High Frequency Welded Fin TubeCarbon Steel TubeCarbon Steel Tube12.70~1601.5~7Fins/Inch0.8~3.2mm. ThicknessStainless Steel TubeStainless Steel TubeAlloy Steel MaterialAlloy Steel MaterialIntegral Copper & Copper Alloy High Fin TubeC12200, C11000, C70600C12200, C11000, C7060015.88~22.235~9Fins/InchMax 12mm.HOval Fin TubeCarbon Steel TubeCarbon Steel TubeAll Size Available5~15Fins/InchStainless Steel TubeStainless Steel TubeAlloy Steel MaterialCopper &Copper Alloy TubeAlloy Steel MaterialCopper &Copper Alloy TubeLow Fin TubeLow Fin TubeAll Kind of Material--9.52~4019~54Fins/InchTurbo-C TubeTurbo-E TubeCorrugated TubeAll Kind of Material--6.35~402~9Fins/InchInner Ridged TubeC12200--7.93~15.8860~75Fins/InchFlower TubeC12200--16.0~19.012~15Fins/InchSpec.

OD range mm

Grade

Chemical composition

Cu %

Sn %

Al %

Ni+Co %

Pb %

Fe %

Zn %

Mn %

As %

P %

ASME SB111

4~200

C12200

≥99.9

-

-

-

-

-

-

-

-

0.015~0.040

4~60

C44300

70~73

0.9~1.2

-

-

≤0.07

≤0.06

Rem.

-

0.02~0.06

-

4~60

C68700

76~79

-

1.8~2.5

-

≤0.07

≤0.06

Rem.

-

0.02~0.10

-

4~60

C70600

Rem.

-

-

9.0~11.0

≤0.05

1.0~1.8

≤1.0

≤1.0

-

-

4~60

C71500

Rem.

-

-

29.0~33.0

≤0.05

0.4~1.0

≤1.0

≤1.0

-

-

Member Information

| SHANGHAI JUYE MATERIAL TECHNOLOGY CO.,LTD | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 15821988586 |

| Contact: | Lyndon (Manager) |

| Last Online: | 21 Jul, 2024 |

Related Products of this Company

-

Precision seamless steel pipe

-

Yellow jacket coating pipe/ Amarillo

US $11.5

-

Inconel tube pipe rod sheet fitting

-

DIN 2391 seamless tube

-

S32760 stainless steel tube

-

Precision stainless steel capillary tube

-

Ship building tube

-

Nickel alloy 276 steel tube steel pipe/

-

309S/309H stainless steel tube

-

Triangle tube for agriculture machine