| ITEM |

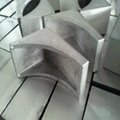

Aluminium die casting motorcycle part

|

| Die casting mould |

|

Single or multiple |

|

|

H13,DIEVAR,QDN,8407,2344V,TQ1,2343,SKD61,

45#steel,etc. |

|

|

Hardened, Nitriding |

|

|

HRC50~55 |

|

|

Advanced design, Logical structure, High precision,

Qualified materials, Long lifetime, Short delivery time. |

| Die casting product |

|

Aluminum alloy,A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3, ADC6, ADC12, ZL104, ZL107. |

|

|

Casting, Deburring, Machining, Surface Treatment, Packing. |

|

|

High quality polishing, Chrome/nickek/Zinc(white, blue, yellow, black)plating, hot galvanized, painting, powder coating, Anodizing, electrophoresis, sandblasting and ect. |

|

|

7-30 days |

| Advantage |

|

in 1990 |

|

|

Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM |

|

|

High, refined, sharp equipment, a more high-speed processing center, walking thread cuttings, precision machine sparks, large grinding machines, CNC engraving machines and 10PCS of die-casting machines ( range from 160 to 1250 Tons). |

|

|

Metal material metallographic analyzer, metal detection machine, coordinate measuring machine, large-scale aluminum material direct reading spectrometer, aluminum material hardness meter, X optical testing machine, tensile testing machine, used from mold manufacturing to samples test. |

|

|

Plentiful experience and skillful technique on die casting |

|

|

ISO9001: |