| Model: | Φ50-Φ160 |

|---|---|

| Brand: | Qingdao Jingke Plastic Machinery |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | Plastic pipe , Solid wall pipe , Upper and lower wate |

| Price: |

¥250000

/ pc

|

| Min. Order: | 1 pc |

Product Description

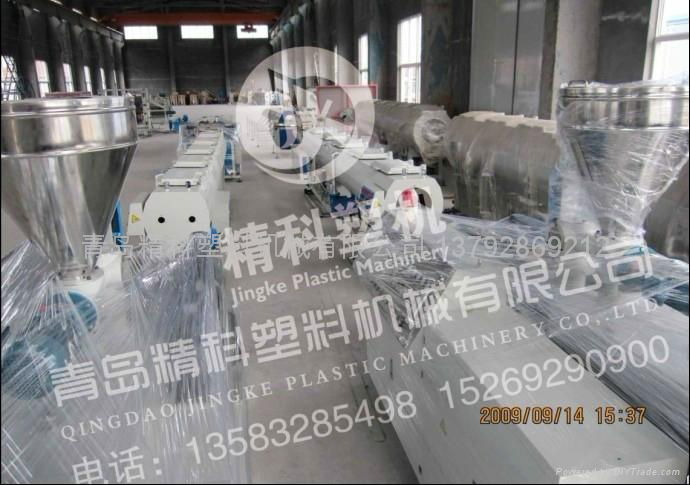

PVC solid wall drain equipment PVC solid wall drain line PVC solid wall drain extrusion equipment PVC water supply drain equipment

Plastic pipe material production line is mainly used in the production of agricultural drainage, construction drainage and laying cable etc and all kinds of pipe diameter and wall thickness of the plastic PVC pipes. The unit consists of a conical twin-screw extruder, vacuum calibrating bench, tractor, cutting machine, such as double material group. Screw extruder and the tractor adopts the imported ac frequency conversion speed regulating device, vacuum pump and drawing motor are all made of high quality products. Tractors have two claws, three feet, four claws, six claw drawing method, etc. Can choose the saw blade cutting type or the planet cutting type, the other belt length gauge and thickening of the device, unit reliable performance, high production efficiency. Our company can according to user requirements, equipped with special devices after wall spiral pipe production unit, the lining of the hollow pipe and the core layer foam pipe.

The whole production line consists of the following main parts:

1, SJSZ - 65/132 conical twin screw extruder

2, SJSZ - 65 host operating control cabinet

3, SL - 50 automatic feeding machine

4, lh-zd - 6000 vacuum sizing spray cooling tank

5, pedrail haul-offs QG - 160

6, JQ - 160 saw blade cutting machine

7, the FZ - 6000 reverse discharging

Eight, the head mould from 50-90 - mm / 110-160 - mm

9, finalize the design mould from 50-160 mm

10, SHR - 200/500 l high-speed heating cooling mixer

11, the SWP - 360 multi-function strong plastic crusher

12 spurt the code machine and computer

Production line features: adopt two different outgoing rotating conical twin screw extruder. Composite co-extrusion machine head, pipe quality, optional with spiral slot within the core rod production and uniform rotation screw foaming and empty wall spiral pipe. Vacuum sizing, tubing and spray cooling, the surface is bright and clean. Adopts centralized control, convenient operation, high degree of automation.

| Payment Terms: | TT |

|---|---|

Member Information

| Qingdao JingKe plastic machinery Co., LTD | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13792869212 |

| Contact: | Tan Xiaoming (The manager) |

| Last Online: | 09 Mar, 2019 |

Related Products of this Company

-

PVC plastic drainage pipe extrusion

-

PVC pipe production line equipment

-

PVC fiber reinforced hose production

-

PVC/PP plastic honeycomb board equipment

US $80000

-

PE plastic pipe production line

-

3 PE big straight buried insulating pipe

-

PVC double screw plastic granulator

-

PVC pipe production line(20-63mm)

US $45000

-

HDPE large diameter double flat wall