| Model: | ZB-R-100CC |

|---|---|

| Brand: | BATTE |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | extrusion gear pump , metering pump , melt pump |

| Price: |

US $5300

/ set

|

| Min. Order: | 1 set |

Product Description

2). Excellent quality assurance;

3). Fast delivery;

4). Worldwide dealer or agent needed.

Batte Melt Pump Zhengzhou Co., Ltd is one of the biggest manufacturer for melt pump, gear pump or metering pump products in China. Being a professional supplier for melt pump products, we have been accumulating adequate experience on the application technique.

Scope of Application

Batte melt pump is mainly used for transportation, pressurization and metering of high temperature or high viscosity polymer melt. It can be applied in the following scope of field:

|

Scope of Field |

Examples |

|

Polymer Melt |

film, pipe, plate, sheet, granulation |

|

High Temperature or High Viscosity Materials |

PC, PMMA, ABS, HIPS, PET, PVB, PS, PP, PA, PE, PVA |

|

Chemical Fiber Melt |

polyester for cotton-fiber, polypropylene |

|

Other Polymer Melt Materials |

rubber, asphalt, paint, adhesives, coatings, lubricants |

Technical Parameter for Melt Pump Model (ZB-R Series):

|

Pump Model |

ZB-R(0.5-2500CC) |

|

Capacity Delivery |

0.1-5400L/H |

|

Recommended Rotation Speed |

5-60rpm |

|

Driven Power |

0.2-55KW |

|

Heating Power |

1-20KW |

|

Working Temperature |

≤400°C(750°F) |

|

Working Pressure |

Output Pressure: ≤40Mpa(6000psi) |

|

Gear Form |

Straight (Optional) |

|

Voltage |

380V/50Hz (Optional) |

|

Sealing Method |

helical sealing, packing sealing, or other optional mechanical sealing |

|

Heating Component: |

Stainless steel heating rod |

|

Tightening Parts: |

12.9 high-strength screws |

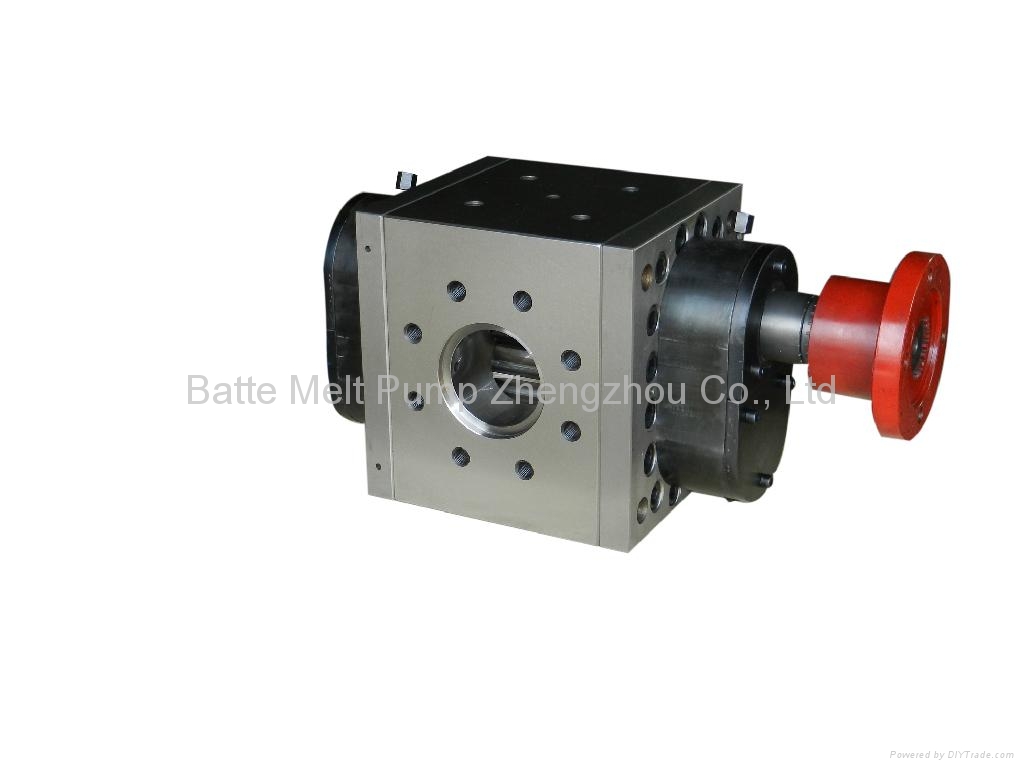

Main Component for BATTE Melt Pump

Pump Housing

Front Cover

Back Cover

Gear

Bearing

Drive Shaft, Non Drive Shaft

Seal

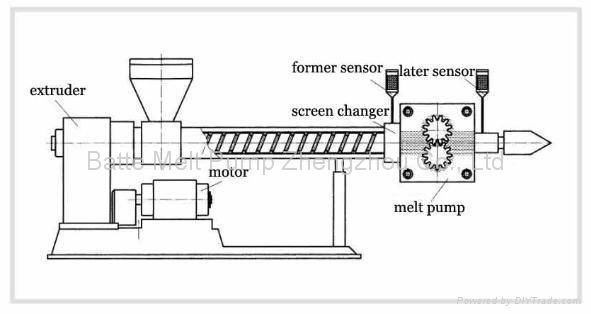

One Whole Set of BATTE Melt Pump System Comprise :

1. Melt Pump

2. Driven Motor System: motor + reducer

3. Control System: PLC touchscreen system

The Performance Advantage of Batte Melt Pump Model (ZB-R Series):

1. Stabilizing outlet pressure;

2. Improving the products quality;

3. Increasing the extrusion output;

4. Reducing unit energy consumption;

5. Prolonging the service time of extruder

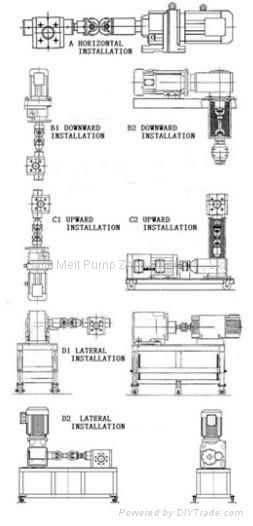

The Installation of Our Melt Pump

Installation Method: Motor+Reducer+Universal Coupling+Melt Pump

Installation Method: Motor+reducer+universal coupling+melt pump

You can use control or direct current governor for the motor, and can adjust the flow to your demands optionally. We s est using servo motor for speed governing if you demand high precision.

Quality Control System

• Fixed Equipments for Q/C

• Qualified Adequately before Reaching Warehouse

• Randomly Checking Machines before Shipment

Our Value-added Service Package

1. Installation Services: During the period of installation and deb ing, we shall offer training about effective operation and maintenance.

2. Technical Services: Our company has been devoting ourselves into offering custom transforming projects for our worldwide clients in the field of medical, chemical engineering, plastics, rubber industries etc.

We can assist our clients to solve all kind of technical problems with our capable technician team, and we own adequate experience for production line transformation as well as formula feeding arrangement.

3. Warranty Services: We offer free after sale service except the engineers' traveling expense for any quality problem occurs during our 12 months warranty period.

CE Certificate for Our Melt Pump Products

Batte Melt Pump Zhengzhou Co., Ltd has already passed the CE Certificate from Safenet Limited.

| Payment Terms: | T/T |

|---|---|

Member Information

| Batte Melt Pump Zhengzhou Co., Ltd | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15838333326 |

| Contact: | Melissa Zheng (Sales Representative) |

| Last Online: | 18 May, 2016 |

Related Products of this Company

-

Micro Single Screw Weight Loss Dosing

US $12500

-

BATTE Single Screw Volumetric Feeder for

US $1500

-

BATTE Twin Screw Loss-in-weight Feeder

US $6000

-

Hopper Twin Screw Weight Loss

US $6550

-

High Pressure Metering Gear Pump for

US $14300

-

BATTE Good Performance Twin Screw

US $2000

-

Gear Pump for Plastic Extruder

US $4000

-

Melt Pump for Plastic Extrusion

US $3200

-

High Efficiency Loss-in-weight Feeder

US $9000

-

BATTE Reinforced Gear Pump for Single or

US $5000