| Model: | KCF02 |

|---|---|

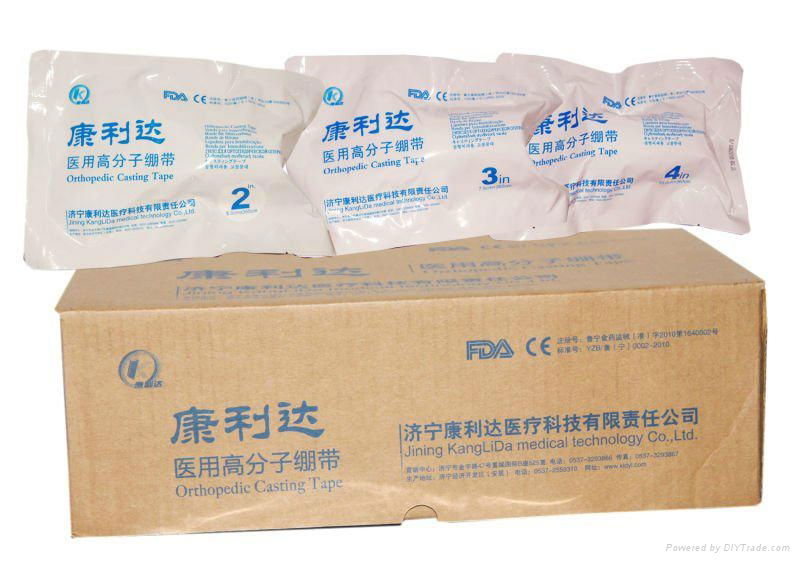

| Brand: | Klida |

| Origin: | Made In China |

| Category: | Services / Therapies |

| Label: | orthopedic bandage , fiberglass bandage , factory manufacturer |

| Price: |

US $1.25

/ roll

|

| Min. Order: | 1000 roll |

Product Description

Specifications

-Harmless to human health

-Curable in 5 minutes

-25 times stronger& 5 times lighter than POPbandag

Orthopedic Fiberglass Casting Tape

[Material ]

The tape is made of multi-layer knitted fiberglass impregnated with water-activated polyurethane resin.

[Character & advantage]

1)Simple operation: Room temperature operation, short time, good molding feature

2) High hardness & light weight

20 times hard than plaster bandage; light material and use less than plaster bandage;

Its weight is plasters 1/5 and its width is plasters 1/3,which could reduce wound burden

3) lacunary (many holes structure) for excellent ventilation

Unique knitted net structure make sure good air ventilation and prevent skin damp and

hot & pruritus.

4) Rapid ossification (concretion)

It ossifies in 3-5 minutes after open the package and could bear weight after 20 minutes,

But plaster bandage need 24 hours for full concretion

5) Excellent X-ray penetration

Good x-ray penetration ability makes X-ray photo clearly without remove the bandage, but

plaster bandage need remove to make x-ray inspection.

6) Good waterproofing quality

The moisture -absorbed percent is 85% less than plaster bandage, Even the patient touch

the water situation, it still could keep dry in the injury position

7) Convenient operation & mold easily.

8) Comfortable & safe to patient/doctor

Material is friendly to operator and it wont become tension after concretion.

9) Wide application

10) Environment friendly

Material are environmental friendly, which could not produce polluted gas after

inflammation.

[How to use Cast](We have video in the website)

1) Put the pad (cotton coil or cotton slipcover) on the surgery position.

2) Wear surgical gloves.

3) Select proper specification according to the surgery position.

4) Immerse the roll in room temperature water(21-24°C) for 4-6 seconds and squeeze it 2-3 times firmly. If the water warmer than 21-24°C shortens the immersing time, while cooler than 21-24°C water lengthens the time.

5) Enwind spirally; Overlapping the previous layer by one-half or two-thirds of the roll width. To maintain proper tension is very important and take care to avoid excessive tightness. The strength can be determined by the number of layers used. Just 3-4 layers provide a string non-weigh-bearing cast and 5-6 layers are typically adequate for weight-bearing cast.

6) Additional after the initial enwinding should be overlapped on itself to achieve good molding. Enwind the roll in 3-5 minutes after immersing in water because after that time it will be concretion.

7) Smooth and rub the surface to achieve good contact between layers. Keeping smoothness helps mold the wrap.

Allow about 10 minutes for sufficient concretion and let patients not move during this time. It could bear electric weight after 20 minutes.

8) It could be windowed, trimmed or removed with traditional cast saw equipment.

Member Information

| Jining Kanglida Medical Technology Co., Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13863729836 |

| Contact: | Emily Ma (Manager) |

| Last Online: | 03 Jun, 2014 |

Related Products of this Company

-

China manufacturer of orthopedic

US $5.65

-

China manufacturer of orthopedic

US $2.1

-

China manufacturer of orthopedic

US $1.25

-

China manufacturer of orthopedic

US $1.8

-

China manufacturer of orthopedic

US $2.45

-

China manufacturer of orthopedic

US $7.85

-

China manufacturer of orthopedic

US $2.85

-

China manufacturer of orthopedic

US $6.5