| Model: | customized |

|---|---|

| Brand: | Atlas |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | Precision CNC machin |

| Price: |

¥6

/ pc

|

| Min. Order: | 5000 pc |

Product Description

Quick Details

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: ATLAS

- Model Number: Customized

- Material: Mild steel bar

- Heat treatment: Anealed

- Finish: Zinc-plated (Cr+6 Free)

- Color: Yellor or siliver or other

- Standard: Nonstandard

- Certification: ISO 9001:2000

- OEM/ODM service: Yes

- Service capacity: One stop solution

Packaging & Delivery

| Packaging Details: | Export cartons + pallet |

|---|---|

| Delivery Detail: | 15 working days |

Specifications

Mould manufactured in house

Focus on OEM/ODM service

Over 20years experiences

Professional communication

Product information

We could supply a wide range of metal parts as per customers drawings and specifications or samples.

Material: carbon steel, alloy steel, stainless steel, cast iron, brass, aluminum and etc.

Machining size range:

- Max. Diameter: 2000mm

- Max. Length: 4000mm

Hardened treatment: surface quenching by high frequency induction or nitrogen treatment, carburizing hardened

Finish: Chromic/Nickel plated or others

- Cooperation model: OEM or ODM

- Design: As per customer specific requirements

- or customer give us the specified sample;

- or the customer conceptual or preliminary design;

- or the customer sketched idea.

- Accept drawing format: .jpg / .dwg / .igs / .stp etc..

- Material: Material stock is of many materials, including

- carbon steel, alloy steel, stainless steel, aluminum, brass even plastics.

- Material condition: The supplying material is on the many conditions, including,

- Bar, forging, casting, extruding and etc.

- Material weight: From 0.01~1000kg

- Application material standard:

- If there is no any specially requirement, we often s uest our customer to try the equivalent China National (GB) standard material that our engineering team proposes which to be properly converted from ANSI, ASTM, SAE, EN, DIN, BS, JIS, and etc., to contribute the material cost control.

- If it is necessary to use exact designated material no., it is also possible choice.

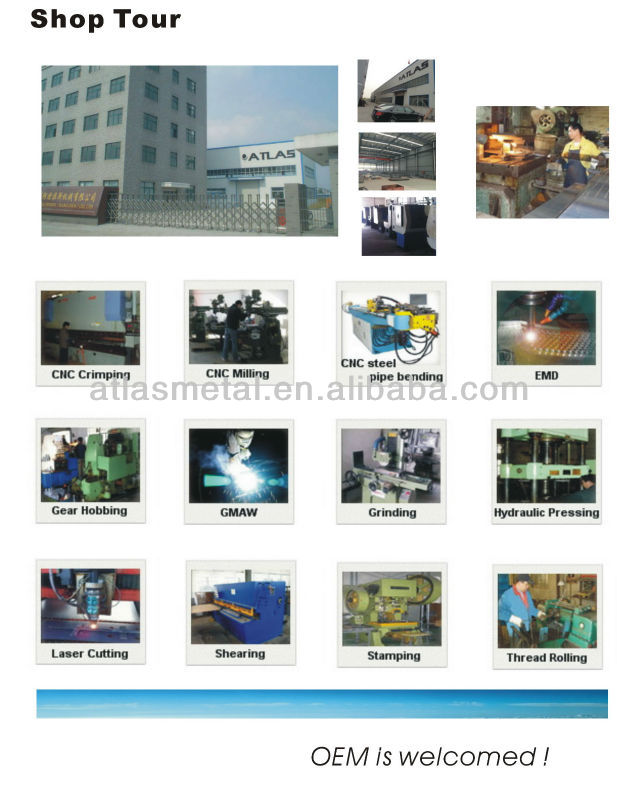

- Available processing (Technique):

- Turning - Milling - Planning - Boring - Grinding - Sawing

- Wire cutting - Gear hobbing - Reaming - Screwing

- Drilling - EDM machining - Assembling

- Precision: Average level: ±0.01mm, depending the part size and thickness and material

- Tooling in house: To design and build the necessary tooling in own house, for the tooling we never add any margins, it just cost.

- Equipment:

- CNC Horizontal lathe machine: 8 sets, Dia. 400mm×2000mm

- Horizontal lathe machine: 2 sets, Dia. 500mm×750mm

- Vertical lathe machine: 2 sets, Dia. 1200mm

- CNC Milling machine: 3 sets, 250mm×1120mm

- Milling machine: 2 sets, 320mm×1320mm

- Planning machine: 1 set, 650mm

- Plane grinding machine: 1 set, 250mm×300mm; precision on and less than 0.016

- Small size high-precision plane grinding machine: 1 set

- Circular grinding machine: 1 set, Dia. 250mm×2000mm

- Vertical drilling machine: 1 set, Dia. 50mm/M24

- Table drilling machine: 15 sets

- Japaness Sodick Linear cutting machine: 1 sets, 320mm×400mm, CNC precision 0.001mm

- Linear cutting machine: 6 sets, 320mm×400mm, CNC precision 0.015mm

- Electric discharge machine: 3 sets, 320mm×500mm, CNC precision 0.018mm

- Gear-hobbing machine: 5 sets

- Sawing machine: 2 sets

- Heat treatment (out house): For the heat treatment, we subcontract to our local qualified supplying factories to process at the out of Atlas house. Generally we can meet any heat treatment requirements on the metal works, such as annealing, normalizing, tempering & quenching, surface hardening and etc.

- Surface treatment: The surface treatment is to do out house. Our suppliers help us to supply our customers a wide range of surface finish solution, such as hot dip galvanizing, zinc plating, nickel plating, chrome plating, powder coating, epoxy painting, anodizing, black oxide, E-coating and etc.

- Inspection:

- Whole inspection procedures (IQC, PQC and FQC) and QA plan are carried out in house to be compliance with the rules and regulation of ISO 9001:2000

- Quality control always be doing on site and on time, never try to do later;

- If the customer found it is necessary any third authorized inspection organization are welcomed to witness the quality before the shipment.

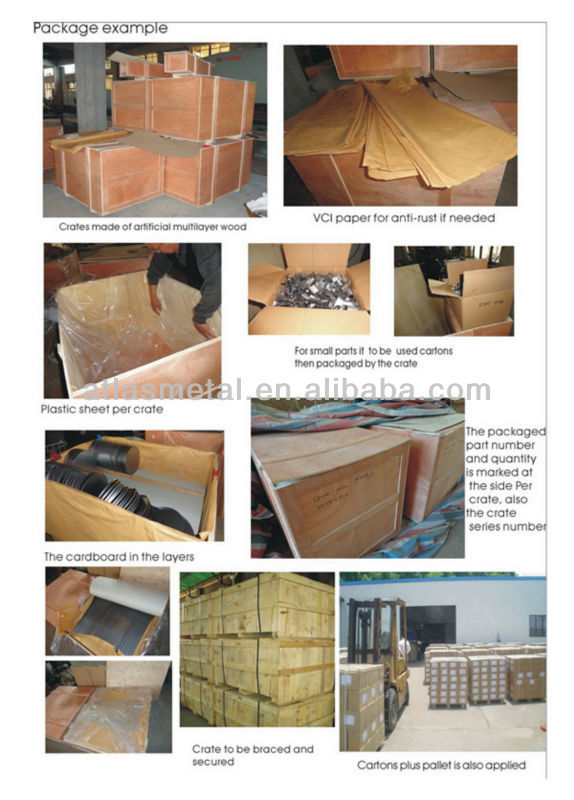

- Packing:

- Strictly in accordance with the customer specific instruction on the packing

- We can package for retail if needed

- If no any specified, generally we would recommend that the parts to be packaged by a poly bags, then put them in cartons, and finally to be on the pallets. The gross weight of one carton is not more than 22kg and pallet size try to approaching 120cm×80cm (Europe size) and 42"×42" (US size)

- The package is seaworthy and suitable for export. The woodern package material shall be steamed with the certificated and stamped by CCIB

- Applicable field: All kinds of auto parts, machinery parts, computer parts, medical parts, home appliances, electrical equipment parts, electrical appliance parts, electronic products parts, electronic parts, generator parts, alternator parts, dynamo parts, electric generator parts, stationery, power switches, miniature swithces, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, etc.

- Reminding:

- The metal parts showed on the Alibaba.com are not for sale, it just for sales promotion purpose it is to explain for our potential customers that we had produced or are capable of making such similar metal parts or supply same metal processing services.

- For any custom metal parts before mass production, we need our customer to confirm and approve the working samples. For more information on the sample issue, please visit our "Sample Procedures and Sample Policy" to get more details.

Product details

Our engineers are in mechanical field for over 40 years. We can give you the most professional solutions on your designs.

Contact us at any time, we will give you the best quotes in two working days.

| Payment Terms: | FOB SHAGGHAI |

|---|---|

Member Information

| Atlas Trading (Hangzhou) Co., Ltd | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 15858102851 |

| Contact: | Steven.Zheng (Sales) |

| Last Online: | 21 Sep, 2015 |

Related Products of this Company

-

Custom ductile iron casting parts

US $25

-

casted steel flange

US $8