| Model: | AMS-DSP |

|---|---|

| Brand: | Amisy Machinery |

| Origin: | Made In China |

| Category: | Industrial Supplies / Animal Husbandry Equipment |

| Label: | fishfeed pellet mill , fish feed extruder , fish feed machine |

| Price: |

-

|

| Min. Order: | - |

Product Description

High capacity and top quality products, our fish feed extruder is a preferred choice for medium or large size feed processing factory and aquaculture farm.

Wet Type Fish Feed Machine Introduction

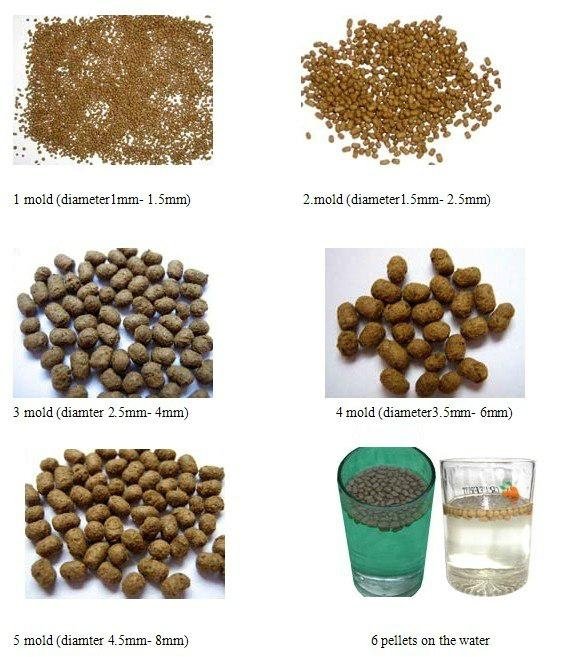

The wet type fish feed extruder is equipped with a boiler which can continuously providing hot steam. It can produce all kinds of floating or sinking aqua feed for fish, eel, shrimp, crab, loach, bullfrog, etc, and can produce many kinds of pet feeds for cat, dog, and etc. The pellet size can be from 0.9-15mm to feed different size fishes. High capacity and top quality products, our fish feed extruder is a preferred choice for medium or large size feed processing factory and aquaculture farm.

Advantages of Fish Feed Extruder

◆ Feeding evenly and constantly: Flat-bottomed scraper mechanism and feeder controlled by transducer make sure that the materials can be fed evenly and constantly.

◆ High efficiency and low power consumption: With conditioner, the steam and water can be directly injected into the extruding chamber through special mechanism, thus the quality and quantity of products can be improved greatly with lower power consumption.

◆ Cutting quickly and accurately: Removable cutting mechanism use knives with good elasticity, which attach to the die plate tenderly and can be regulated in six directions, can be operated quickly and accurately.

◆ Wide application: Variably configurations of screw bolts can match the producing demands for different formulas and raw materials.

◆ Longer service life: Screw bolts and dies are processed through vacuum quench treatment, also be processed with high processing precision and have a long using longevity.

◆ Easy operation: All the operating parts like steam valves, etc, adopt the humanization design, in order to facilitate actual operations.

Superiorities of Wet Type Fish Feed Extruder Conditioner

▶ Screw sleeve adopts jacketed construction, which can be injected in with hot steam or cooling water, thus the extruding temperature can be controlled effectively.

▶ The conditioner can make the materials have fully gelatinization of starch by a combination of hot steam and mechanical shear/mixing. The materials may remain in the conditioner for a time over 180s.

Parameters of Wet Type Fish Feed Extruder

|

Model |

Capacity

|

Main power |

Feeding power

|

Screw diameter

|

Cutting power |

Conditioning power |

|

AMS-DSP60 |

0.18-0.20t/h |

15kw |

0.4kw |

60mm |

0.4kw |

0.37kw |

|

AMS-DSP70 |

0.30-0.35t/h |

18.5kw |

0.75kw |

70mm |

0.4kw |

1.1-1.5kw |

|

AMS-DSP80 |

0.40-0.45t/h |

22kw |

0.75kw |

80mm |

1.5kw |

1.5-2.2kw |

|

AMS-DSP90 |

0.50-0.55t/h |

37kw |

1.1kw |

90mm |

2.2kw |

2.2-3.0kw |

|

AMS-DSP120 |

0.7-0.8t/h |

55kw |

1.1kw |

120mm |

2.2kw |

2.2-3.0kw |

|

AMS-DSP135 |

1.0-1.2t/h |

75kw |

1.5kw |

135mm |

3.0kw |

3.0-4.0kw |

|

AMS-DSP160 |

1.8-2.0t/h |

90kw |

2.2kw |

155mm |

3.0kw |

4.0kw |

|

AMS-DSP200 |

3.0-5.0t/h |

132kw |

2.2kw |

195mm |

4.0kw |

5.5kw |

Member Information

| Zhengzhou Amisy Trading Company Limited | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 65866393 |

| Contact: | Linda Liu (sales representative) |

| Last Online: | 01 Apr, 2014 |