PP hollow plastic building templates extrusion line overview:

Uses and characteristics: PP plastic template production line is the company absorbing foreign advanced extrusion technology and independent innovation and the successful development of invention, plate thickness range can be done 8-18mm, sheet width according to customer requirements 915-1220mm. Its production products smooth surface, size of the error is small, having nailed, planed, corrosion-resistant, flame-retardant and many other advantages.

The unit has two single-screw extruder, hydraulic screen changer, mold, molding machine, a traction machine, annealing furnace, cooling box, the second traction machine, cutting machine, conveyor components. Compared with the traditional architectural templates template, it has the following characteristics:

1 water resistance. Even if it is completely immersed in water for several days, it will not deform due to damp. Will not rot rust.

(2) incompatibility with the cement, sticky, easy stripping after construction, will not result in cement adhesion and deformation.

3 construction, high efficiency, good quality. Construction of the building with its smooth surface, without a second modification.

4 Save the process, improve the efficiency of construction. While also in the processing template, the template surface pretreatment, to obtain the desired wall pattern.

5 Light weight, convenient construction, the use of high efficiency

6 support, high strength, not easily deformed.

7 cost.

8 long life, be used many times. Eventually damage the plastic template can still crush again, reprocessed into new template, save resources, in line with the "green industry" requirements.

9 good insulation will help shorten the construction cycle.

10 timber can be added various processing methods, can be welded, it can be flexible at the construction site for secondary processing.

Widely used:

Transportation: boats, planes, buses, train cars, roof, envelope core, interior panels.

Construction, decoration industry: building wall panels, interior panels, residential, office, public places between buildings, commercial decorative frame, clean room panels, ceiling panels, kitchenware, sanitary ware.

The advertising industry: screen printing, computer lettering, advertising signs, displays, signs with the board.

Industrial applications: chemical corrosion engineering, thermoforming parts, refrigerator panels, special cold project, environmental protection plate.

Other uses: template, sports equipment, breeding materials, waterfront facilities, moisture, water timber, art materials, a variety of portable partitions.

Specifications Introduction

Average weight thickness specifications

12mm 915mm × 1830mm 21kg

15mm 915mm × 1830mm 26kg

12mm 1220mm × 2440mm 37kg

15mm 1220mm × 2440mm 45kg

Various templates performance comparison

Performance bamboo wood plastic template template

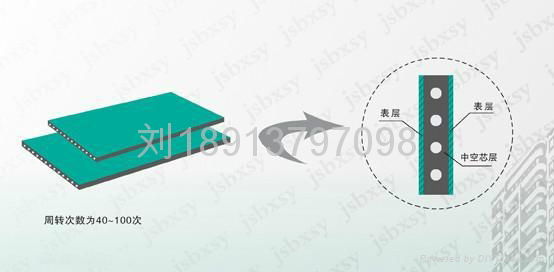

Turnaround times of 40 to 100 times 6-8 times 3-6 times

Do not wear do not wear abrasion resistant

Poor Poor corrosion resistant

Toughness can not not arched template

Poor poor impact strength of high strength

Drop altitude drop test does not break easily damaged easily damaged

After absorbing deformation deformation deformation damage damaged

Disposal of recyclable scrap can not be recycled can not be recovered

Environmental pollution Environmental pollution Environmental Pollution

Product superiority:

Kingwell new mold production line plastic template does not absorb moisture, corrosion, acid and alkali, especially for underground and humid environments,

Plastic template, high strength, impact resistance, wear resistance, long life, turnover frequency of use of up to 40 to 100 times;

Plastic template, light weight, easy form removal expenses, handling operation, low labor intensity, high construction efficiency;

Plastic template surface is smooth, smooth, without brushing mold release agents, reducing cleaning and maintenance costs;

Plastic template good processability, planing, sawing, nailing, both with wooden template and use;

After use of waste board, scrap recyclable, cost savings and reduce pollution.

In short plastic template with the use of conventional formwork commonalities and more features than the Normal template.

Plastic template will become the twenty-first century global construction plastic and wood, plastic and steel, plastic and bamboo the ideal product.