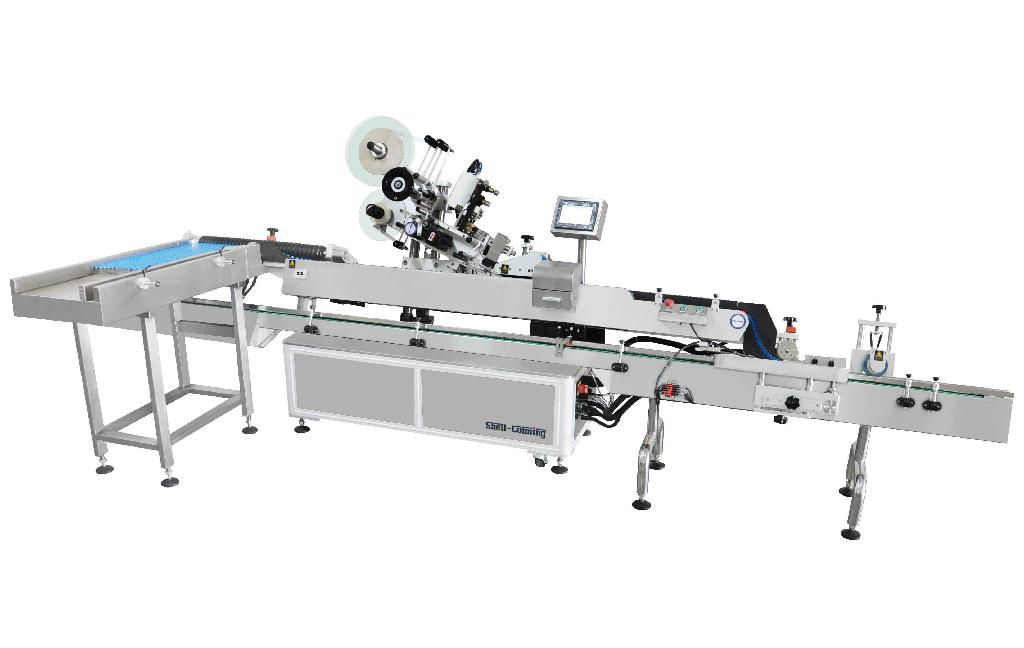

| Model: | SLA-605 |

|---|---|

| Brand: | Shell_Conning |

| Origin: | Made In China |

| Category: | Industrial Supplies / Packaging Related Machine |

| Label: | Labeling Machine , Self Adhesive Label , Horizontal Label |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Main technical parameters:

|

Model No. |

SLA- 605 Horizontal Round Bottle Labeling Machine |

|

Bottle Type & Size |

Diameter: Φ1—20ml Φ7-20ml |

|

Labeling Speed |

600 /bpm( Related to the Bottle size/ Label type) |

|

Stop Labeling Precision |

±0.3mm |

|

Labeling Machine Precision |

±0.5mm |

|

Use environment Temperature |

5-45℃ |

|

Use environment humidity |

15-90% (non-condensing ) |

|

Width of Conveyer belt |

Can according to customer material’s features make the Width and Length of the Conveyer Belt ) |

|

Machine Outer Size (mm) |

(L):4000mm*(W)1600mm*(H)1600mm |

Main Application :

The machine is widely application for :Pharmaceutical& Medical industry on small round bottle for High speed labeling equipment ,the labeling speed up to 600 bottles /min.

Product Details:

- Type: Labeling Machine

- Condition: New

- Application: Medical/pharmaceutical ,

- Driven Type: electric & pneumatic

- Automatic Grade: Automatic

- Voltage: 220V/50HZ

- Power: approx 1000W

- Packaging Type: Bottles

- Packaging Material: Good wooden case

- Brand Name: Shell-conning

- After-sales Service Provided: Engineers available to service machinery overseas

Main Function :

Vertical big –capacity feeding conveying device

a : Adopt vertical feeding make the material more convenient and greatly reduce the labor intensity when supplying materials

b : Vertical Turn horizontal feeding material

The Vertical Turn horizontal mechanism :ensure the material form Vertical turn to horizontal institution make bottles with thread road caressing all the way ,this process greatly reduced the rate of bottle broken

C: Horizontal labeling device :

The roller conveying belt adopts tilting design ,to ensure the products at the same datum ,make the labeling more accurate and more stable .

d: Bottle Inserting tray buffer storehouse

Adopt seamless connecting design ,made stick label into the tray storehouse more smoothly ,has the overload warning system in the buffer storehouse .

e : Servo inserting tray bibcock

Fluid type discharge passage make bottles feeding without resistance ,itself gravity blanking is more smooth ,the whole servo bottle inserting tray wheel make the job more precision .

f : Servo trays with clamping belt

Adopt the whole servo design with servo bottle inserting tray to realize precise one-to-one match .make the bottle inserting tray by one step .

g : Dynamic pressure mechanism

Adopt itself gravity insert bottles press into tray ,make the job more perfect

h :High speed hot-iron printer :Automatic high speed hot –iron printer

Synchronization function:

After that the labeling itself can auto- into the bottle tray ,perfect the line of production ,feeding printing ,labeling ,bottle inserting tray by one match

a :Can be equipped with printing equipment or hot-iron printer to realize synchronous printing production date and related information.

b: Flexible automatic connection production line and single use

The main performances and features:

1 Horizontal roller conveyor belt feeding effectively solves the small bottle is not convenient for vertical feeding problems. Horizontal label to bottle body as a calibration point ,ensure the labeling precision

2 Video detection device provides a variety of detection function, such as label labeling detection, leak detection and code printing content detection; unqualified bottle will be removed and recovery

3 Automatic lifting hopper device make the operator on a horizontal table easily, easy loading, supplementary materials, double hopper design make the materials supplementary more smooth, To provide a guarantee for the uninterrupted supply of materials .

4 New model into the bottle inserting tray device ,to realize high speed accurately put the labeling well bottle into the bottle inserting tray

5 Bottles of supporting multiple detection orientation , high rate of tray

6 Through the bottle tray conveyor belt by manual split tray , or install split

machine realize automatic split tray .

7.Inserting tray buffer storehouse completely synchronized with the label ,less tray ,the labeling speed will be slowing ,without bottles the tray automatic stop waiting .

8,The Feeding Material mechanism adopt “S” shape design can effectively buffer and reduce pressure the bottle feeding

9,Glass protective cover device: can effectively protect personal safety .

10.Label intelligent management, the label soon used up warning or shutdown.

11.The Send mark device adopts imported high torque, small inertia servo motor drive, the Swiss steel sand roller technology, never deformation, friction is excellent, large angle determines not to slip characteristic ensures high precision operation give mark function.

12.Adopt the world famous brands imported electrical components, ensure the stability and reliability.

13.The Cabinet adopt SUS 304 stainless steel and aluminum alloy material ,With GMP requirements .

14.PLC combined with LCD touch screen pannel, the setting and operation is clear and easily.

15.The machine has many functions such as guiding, labeling, attaching, counting

16. The labeling position can be adjusted.

17. The machine can be used in production line with conveyer belt.

18. The special machine can be customized according to customer requirement

Packaging & Delivery

|

Packaging Details: |

Packed in wooden case with well-supported materials wrapped |

|

Delivery Detail: |

Delivery within 25 working days after receipt of deposit |

Member Information

| GuangZhou Shell_Conning Mechanical Equipment Co.,Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13711237881 |

| Contact: | Angel Zhou (Sales Manager ) |

| Last Online: | 22 Nov, 2013 |

Related Products of this Company

-

Electronic Cigarette Labeling Machine

-

Big Bucket Double Flank Labeling

-

16) Clamping Belt Plane Labeling Machine

-

Single Flank Star Wheel Round Bottle

-

Vertical Roller Round BottleLabeling

-

Semi-automatic Round Bottle Labeling

-

Toothbrush Plane labeling machine

-

High -Speed Paging Flat Labelig Machine

-

Plane Corner labeling machine

-

Star Wheel Round Bottle Labeling Machine

US $19200