| Model: | - |

|---|---|

| Brand: | LiHua |

| Origin: | Made In China |

| Category: | Chemicals / Other Chemicals |

| Label: | Honeycomb Ceramic , Honeycomb Catalyst , Ceramic Packing |

| Price: |

US $15

/ pc

|

| Min. Order: | 1000 pc |

Product Description

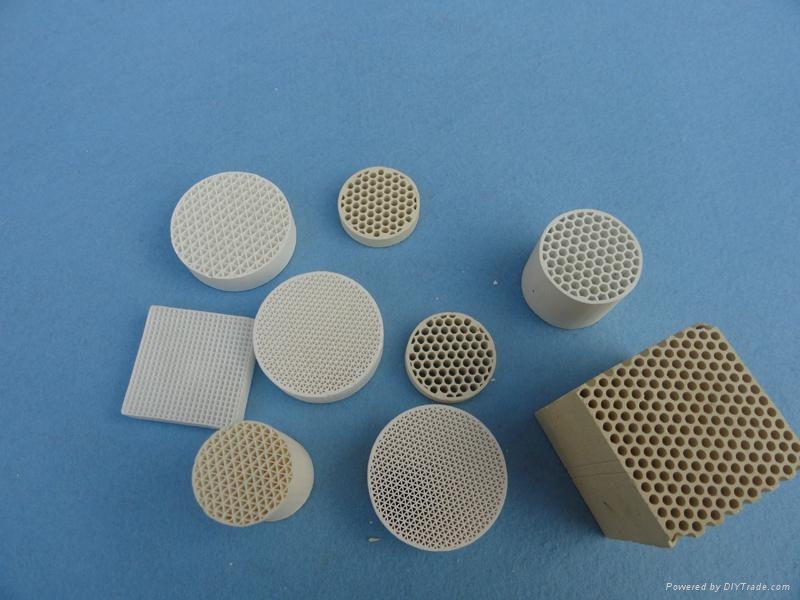

Ceramic Honeycomb Substrate

1.Specifications

Type:alumina,mullite,dense cordierite,porous cordierite,mullite cordierite,stoneware

High surface area, large heat capacity, low coefficient of thermal expansion, resistance to corrosion and high temperature, ceramic honeycomb monoliths have been well used in chemical, metallurgical, gas and environmental protection industries. The main

Usage is as follows:

*Tower packings--With high surface area, even distribution of fluid and efficient in mixture separation in chemical & petrochemical industries.

*Catalyst carriers--Reduce the oxidation temperature of VOC in purification of industrial exhaust gases in RCO systems and automobiles.

*Regenerative heat step-up transformer--Large heat capacity, low resistance to fluid and energy saving up to 40-70% in RTO systems.

*Gas combustion distributor--Distribute the heat uniformly, and make the combustion completely. It can save energy more than 10%.

*Kiln furniture in refractory industries--Low bulk density and high thermal efficiency.

2. Physical & Chemical Properties of Honeycomb Monoliths

|

Type Item |

Alumina |

Mullite |

Dense Cordierite |

Porous Cordierite |

Mullite- Cordierite |

Stoneware |

|

|

|

Al2O3 |

48-55 |

66-72 |

32-36 |

32-37 |

55-65 |

20-26 |

|

SiO2 |

40-45 |

25-30 |

45-52 |

46-52 |

28-36 |

68-75 |

|

|

MgO |

|

|

5-8 |

8-12 |

2.5-3.2 |

0.2-0.3 |

|

|

K2O+Na2O +CaO |

4.0-5.5 |

≤1.0 |

≤3.0 |

≤2.0 |

≤1.0 |

2.5-4.0 |

|

|

Density,g/cm3 |

2.7 |

2.9 |

2.4-2.6 |

1.9-2.0 |

2.9-3.2 |

2.3-2.5 |

|

|

Coefficient of

|

5-7 |

5.5-6.5 |

2.5-3.5 |

1.3-2.5 |

2.5-4.0 |

5-7 |

|

|

Heat capacity

|

800-900 |

1100-1300 |

800-1200 |

750-900 |

850-1100 |

840-920 |

|

|

Thermal conductivity

|

1.5-2.5 |

1.5-2.0 |

1.5-2.58 |

1.3-1.5 |

1.5-2.3 |

1.0-1.2 |

|

|

Spalling resistance,°C |

≥150 |

≥350 |

≥250 |

≥360 |

≥250 |

≥150 |

|

|

Max Working temp.°C |

1300 |

1600 |

1300 |

1300 |

1400 |

1300 |

|

3. Type and Size of the Product

|

Type Item |

1 |

2 |

3 |

4 |

5 |

6 |

|

Number of channels |

5×5 |

13×13 |

20×20 |

25×25 |

40×40 |

50×50 |

|

Channel density,cm-2 |

0.15 |

1 |

2 |

3 |

7 |

11 |

|

Width of channel,mm |

26.3 |

9.2 |

6.4 |

4.9 |

3.0 |

2.3 |

|

Thickness of wall,mm |

2 |

1.5 |

1.2 |

1.0 |

0.7 |

0.7 |

|

Surface area,m2/m3 |

117 |

278 |

455 |

540 |

825 |

1005 |

|

Free cross-section,% |

77 |

74 |

73 |

67 |

65 |

57 |

|

Size,mm |

Standard sizes 150×150×600/450/300/150/100/50

|

|||||

4. Reference--US Steel Company

General Manager Mr Aihuai Wang and vice General Manager Mr John were invited to visit US Steel

Company for cooperation and technical advice during the loading and testing of catalysts on Oct.2010.

Member Information

| Pingxiang LiHua Packing Co.,Ltd. | |

|---|---|

| Country/Region: | Jiang Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 18979961389 |

| Contact: | Willa Wang (Sales Manager) |

| Last Online: | 01 Apr, 2016 |

Related Products of this Company

-

Activated Alumina

US $1650

-

Plastic Random Packing

US $350

-

Ceramic Ball

US $300

-

Molecular Sieves

US $1500

-

Ceramic Random Rings

US $350