| Model: | XSG Series |

|---|---|

| Brand: | Suncheer |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Drying Machine |

| Label: | rotating drier , drying machine , drier |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

DESCRIPTIONS:

XSG series high speed rotating drier is developed by our factory, and its’ technology is based on advance technology adored. The machine is including lots of superiorities, such as reasonable design, compact structure, wide utilization, great productive capacity, good quality, high effect and save energy. Drying, grinding and sieve are completed in one equipment in once time. It eliminates pollution and the technology is reached international advance level.

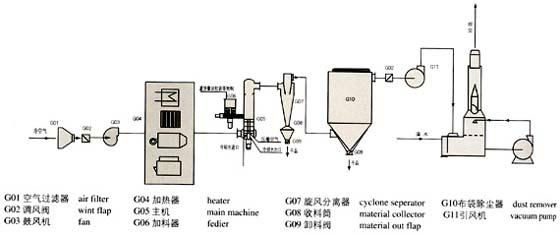

PRINCIPLE:

Hot air enters into stirring and crushing and drying chamber from the bottom of drier with suitable atomizing speed. It exerts strong shearing, blowing, floating and rotating effect to raw material. There fore raw material is granulated through centrifuge, shearing, impacting and friction effect. It strengthens the process of gear exchange. At the bottom of drier, the lager and damp granule is crushed under the action of stirrer and the granule that is small in partial and contain less moisture will lift accompanied with revolving air stream. During the period of lift, it is dried further. Because gas and solid two phase flow in rotating and the inertia of solid phase is more than that of gas and the relative velocity between solid and gas phase is large, so it strengthens the process of heat exchange. Therefore the machine has strong drying capacity.

FEATURES:

●There are many kinds feeding equipment for choosing, and feeding is continue and static.

●At the bottom of drier, where is high temperature area, heat sensitivity raw material can not contact with heat surface directly, therefore it solves the carbonized and changed color problems of heat sensitivity raw material.

●There are air pressure equipment and shaft equipment, so can longer life of machine.

●There is special equipment for sharing wind, and raising the amount of amount of hot air.

●There are rotational flow pieces inside the drying chamber. It is used to control the moisture and granule of raw material to needed level.

●The density will be added in the machine.

●Because gas speed at circle inside the drying chamber is high and the staying time of raw material is short, high efficiency and quick speed can be realized. It is possible for small equipment to carry out large-scale production.

APPLICATION:

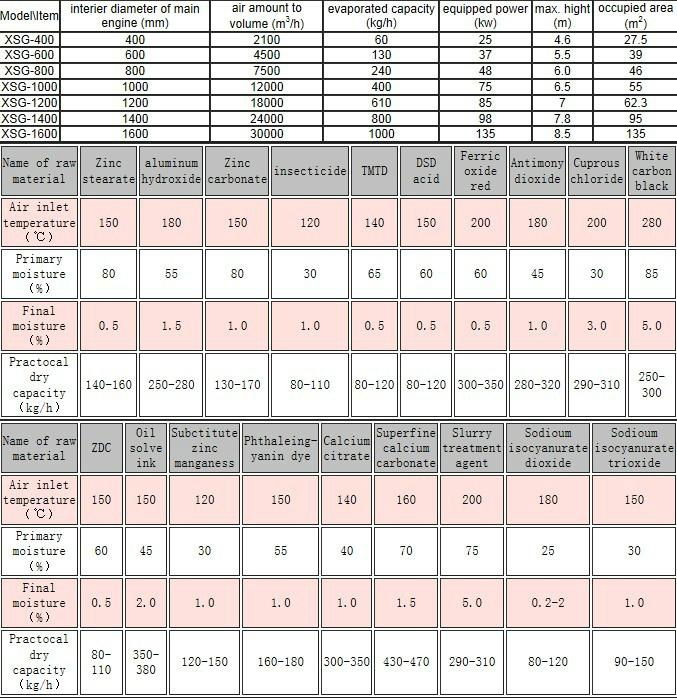

1.Inorganic compounds: borax, calcium carbonate, hydroxide, copper sulfate oxide, barium carbonate, antimony trioxide, all kinds of metallic hydroxide, all kinds of heavy metallic salt, synthetic cryolite and so on.

2.Organic compounds: fenatrol (insecticide of agrochemicals), cadmium laurate, benzoic acid, germicide, sodium oxalate, cellulose acetate and so on.

3.Ceramics: kaoline, silicone trioxide, clay and so on.

4.Dyestuff: anthraquinone, black ferric oxide, indigo blue pigment, butyric acid, titanium hydroxide, zinc sulfide, all kinds of intermediate of azo dye-stuff.

5.Foodstuff: soya protein, agglomerative starch, less, triticin, wheat starch and so on.

Member Information

| Changzhou Suncheer Drying Equipment Co,.Ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 06111496 |

| Contact: | Jolie Liu (foreign trade) |

| Last Online: | 07 May, 2014 |