| Model: | QMY4-45 |

|---|---|

| Brand: | Wins the brand |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | Mobile brick machine , block machine , brick machine |

| Price: |

¥10000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Custom processing: it is type: concrete machinery molding cycle: 45 (in seconds)

Mode of transmission: mechanical transmission of vibration frequency: 2000 maximum pressure (times/min) : 15 (KN)

The weight: 1 (t) vibration frequency: 60 (hz) working pressure: 15 (Mpa)

Dimension: 136 * 130 * 130 (cm) capacity: 6.65 (kw) of the molding pressure: 30 (t)

Main vibration forms: mould vibration total power: 6.65 (w) : brand wins

Model: QMY4-45 alias: mobile brick making machine use: production of hollow bricks

Use the machine to produce models of hollow block, standard bricks, planting grass brick, etc., this machine is suitable for work in the level of the cement surface, forming a mold, will die box rises, gong plate rotation, through the chain wheel drives the driving wheel moving forward, turning with a universal steering, save work the machine, to save time, save plate, small investment, quick effect.

Three, technical parameters

Molding blocks:

390 x 190 x 190 4 / die

390 * 240 * 240 3 piece/die

390 x 120 x 190 6 pieces/die

Molding cycle: 40 said

Vibration frequency: 48 hz

Power: 5.5 KW

Vibration force: 24 kn

Weight: 1000 kg

Installation dimensions: 1700 * 1500 * 1500 (length x width x height)

(a) after the installation machine approach, first check the machine in the process of transportation for parts damage, various fasteners loose phenomenon, if found out in time, and then check whether the site is level off, the power cord should be set up, best should not be on the ground.

(2) the first will join the gear reducer as required, the lubrication parts into the lubricating oil, test for a conform to the requirements of the electrical power supply, after being checked, connected to the power and deb ing of the die and mould box first whether the up and down freely, observe whether jam phenomenon such as friction, if you have to adjust, until we die in the die box up and down freely.

The die and mould deb ing after mold, cases filed at the same time, after being on hooks in the die head, drop molding box, and then mixing good material with spade shovel into the molding box, reliable foot after starting under vibration motor after 3 ~ 5 s, stop, and then rake materials uniform will be full of mold material box, drop die head, start up and down the vibrator at the same time, after putting in place to limit lever for both sides to stop vibration, eliminate the residual vibration, start the boost motor, after waiting for molding block completely out of the box to stop, then turn the gong plate, drive the machine moving forward after leaving the forming block to stop, a cycle is complete. Insufficient to start a new line needs to be on the spot, with universal steering the host easily put to the appropriate location.

Five, the replacement of mold

(a) remove the mould

(1) open die

Lower die first rise at the same time, after waiting for mould in the bite, drop molding box, carton for mould and die head pressure Angle separation stop about 60 mm, and then put the plate on the molding box, improve molding box, mould box pressure head on to stop, and then open mold head each wire positioning, remove the vibrator, landing module box, at this point, the die head with the molding box, such as after the bottom has to stop, carried off the die.

(2) the devanning die

The vibrator on the molding box will be removed first, and then connect the mold on both sides of the box on the ear plate sliding sleeve wire apart, can will die box can be carried out.

(2) to install mold

Will have to change the mold of the die and mould box, first lift the mould box to install molding box, looking for a good mold the ear plate on both sides of the box, set a bit later, after the ear plate welded into the molding box, and then install the vibrator on the molding box, tighten connection plate, bolt.

After changing the molding box, the mould box placed on a plate, the die head, and then improve molding box upward, together with the die head until die plate after contact with the roof above namely stop, and then fixed die head gently, whereabouts molding box, remove the plate, again will die head into the die mould box to box, such as the die head in steel mold up and down freely, fixed die head, vibrator.

Adjust the block height adjustable limit lever on both sides.

General troubleshooting

A different, height of block to or askew, adjust the limit lever or whether the ground is flat on both sides.

Second, the vibration time is too long demoulding is hard, mixture ratio, viscosity large or unreasonable vibration for the first time is too long, need to change the ingredients, reduce vibration time for the first time.

Three, are not very abnormal vibration power: the power supply do not conform to the requirements of the electric equipment, lines or electrical failure, change the power supply, repair or replacement lines or electrical appliances.

Four, block is easily broken after demoulding: improper ingredients, vibration time is too short, no vibration or eliminate residual vibration demould, change the ingredients, to extend the time of vibration, repair or replace the vibrator, such as mold release after eliminating residual vibration.

| Payment Terms: | TT / LC |

|---|---|

Member Information

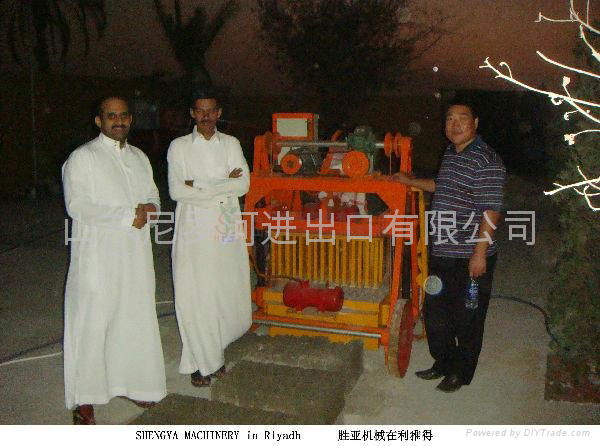

| Shandong sheng machinery co., LTD | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15666195782 |

| Contact: | liyang (salesman) |

| Last Online: | 20 Jun, 2016 |