| Model: | IDS |

|---|---|

| Brand: | UPM Heat Shrink |

| Origin: | - |

| Category: | Electronics & Electricity / Other Electrical & Electronic |

| Label: | Identification Sleev , Mark sleeve , Insulation tube |

| Price: |

US $2

/ m

|

| Min. Order: | 100 m |

Product Description

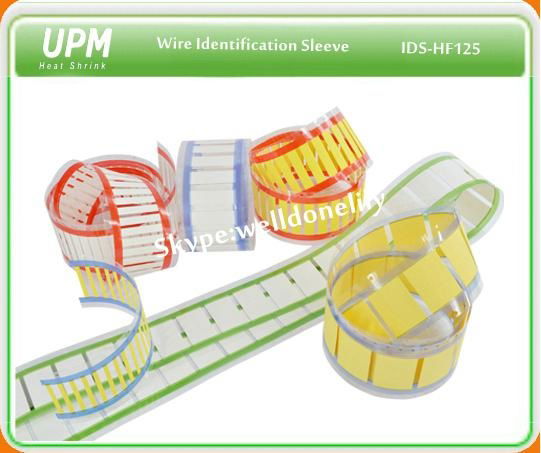

IDS-HF125 Halogen Free Heat Shrinkable Polyolefin Identification Sleeves

IDS-135 Military Grade Heat Shrinkable UV Protection Sleeve for Markers

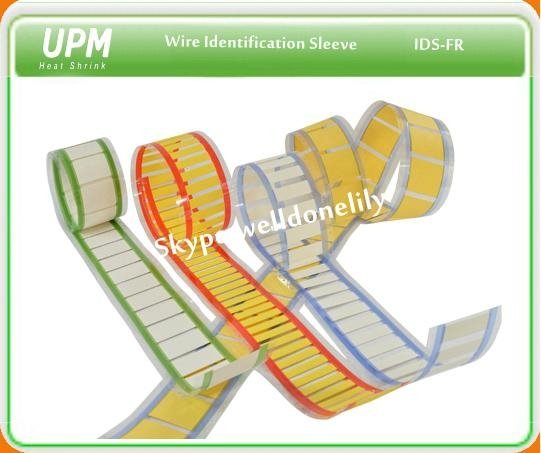

IDS-FR Fluid Resistant Heat Shrinkable Polyolefin Identification Sleeves

IDS-HT225 Military Grade High-temperature Resistant Heat Shrinkable Identification Sleeves

IDS-HF125 Halogen Free Heat Shrinkable Polyolefin Identification Sleeves

Features

* Cross linked polyolefin *Flexible,flame retardant

*Excellent printing property, permanent identification

*Easy to be printed *Halogen free, RoHS and REACH compliant

*Excellent electrical, physical, chemical and printing properties.

*Operating temperature: -55~125 ℃ Shrink temperature:110 ℃

*Shrink Ratio:2:1& 3:1

Standards

UL224 125℃ 600V SAE AS 81531,MIL-STD-202

| Dimensions | |||

| Reference | As supplied(mm) | After recovered(mm) | Size for conductor |

| UPM IDS-HF125 | ID min. | ID max. | mm |

| Shrink ratio: 3:1 | |||

| 2.4 | 2.4 | 0.8 | 0.9-2.0 |

| 3.2 | 3.2 | 1.1 | 1.1-2.7 |

| 4.8 | 4.8 | 1.6 | 1.8-4.1 |

| 6.4 | 6.4 | 2.1 | 2.3-5.5 |

| 9.5 | 9.5 | 3.2 | 3.5-8.1 |

| 12.7 | 12.7 | 4.2 | 4.6-10.8 |

| 19.1 | 19.1 | 6.3 | 7.0-16.3 |

| 25.4 | 25.4 | 8.5 | 9.3-21.6 |

| Shrink ratio: 2:1 | |||

| 2.4 | 2.4 | 1.2 | 1.3-2.3 |

| 3.2 | 3.2 | 1.6 | 1.7-3.1 |

| 4.8 | 4.8 | 2.4 | 2.5-4.7 |

| 6.4 | 6.4 | 3.2 | 3.3-6.3 |

| 9.5 | 9.5 | 4.8 | 4.9-9.0 |

| 12.7 | 12.7 | 6.4 | 6.6-12.0 |

| 19.1 | 19.1 | 9.5 | 10.0-18.5 |

| 25.4 | 25.4 | 12.7 | 13.0-24.5 |

| 38.1 | 38.1 | 19.1 | 21.0-37.0 |

| 50.8 | 50.8 | 25.4 | 27.0-48.0 |

| Technical Data | ||||

| Property | Test method | Values | ||

| Physical | Longitudinal shrinkage | ASTM D 2671 | ≤5% | |

Tensile strength  |

ASTM D 2671 | ≥12 MPa | ||

| Breakdown elongation | ASTM D 2671 | ≥300% | ||

| Aging(158℃/168hrs) | Breakdown elongation | ASTM D 2671 | ≥200% | |

| Heat shock | ASTM D 2671 | No cracking | ||

| Low temperature flexibility(-55℃/4hrs) | ASTM D 2671 | No cracking | ||

| Electrical | Dielectric voltage Withstand | ASTM D 2671 | 2500V,60s No breakdown | |

| Volume resistivity | ASTM D 2671 | ≥1014Ω.cm | ||

| Dielectric strength | ASTM D2671 | ≥20 KV/mm | ||

| Chemical | Flammability | ASTM D 2671 | Self-extinguish in 60s | |

| Copper corrosion | ASTM D2671 | No corrosion | ||

| Printing performance | SAE AS81531

MIL-STD-202 |

50 rubs, legible

30 strokes, legible |

||

| Fluids resistance (23℃/24hrs) | SAE AS81531 | Printing legible | ||

Typical application

* Special designed to meet the requirements of identification of wire and cables

IDS-135 Military Grade Heat Shrinkable UV Protection Sleeve for Markers

Features

* Cross linked polyolefin * Flexible, highly flame-retardant.

* Excellent printing property, permanent identification

* Excellent electrical, physical, chemical properties.

* RoHS and REACH compliant

*Operating temperature: -55~135 ℃ *Shrink temperature:110 ℃

*Shrink Ratio:2:1& 3:1 *Military grade

Standards

UL224 125℃ 600V VW-1 SAE AMS-DTL-23053/5 SAE AS 81531,MIL-STD-202

| Dimensions | |||

| Reference | As supplied(mm) | After recovered(mm) | Size for conductor |

| UPM IDS-135 | ID min. | ID max. | mm |

| Shrink ratio: 2:1 | |||

| 2.4 | 2.4 | 1.2 | 1.3-2.3 |

| 3.2 | 3.2 | 1.6 | 1.7-3.1 |

| 4.8 | 4.8 | 2.4 | 2.5-4.7 |

| 6.4 | 6.4 | 3.2 | 3.3-6.3 |

| 9.5 | 9.5 | 4.8 | 4.9-9.0 |

| 12.7 | 12.7 | 6.4 | 6.6-12.0 |

| 19.1 | 19.1 | 9.5 | 10.0-18.5 |

| 25.4 | 25.4 | 12.7 | 13.0-24.5 |

| 38.1 | 19.1 | 19.1 | 21.0-37.0 |

| 50.8 | 25.4 | 25.4 | 27.0-48.0 |

| Shrink ratio: 3:1 | |||

| 2.4 | 2.4 | 0.8 | 0.9-2.0 |

| 3.2 | 3.2 | 1.1 | 1.1-2.7 |

| 4.8 | 4.8 | 1.6 | 1.8-4.1 |

| 6.4 | 6.4 | 2.1 | 2.3-5.5 |

| 9.5 | 9.5 | 3.2 | 3.5-8.1 |

| 12.7 | 12.7 | 4.2 | 4.6-10.8 |

| 19.1 | 19.1 | 6.3 | 7.0-16.3 |

| 25.4 | 25.4 | 8.5 | 9.3-21.6 |

| 38.1 | 38.1 | 13.5 | 15.0-33.0 |

| 50.8 | 50.8 | 17.5 | 19.0-48.0 |

| Technical Data | ||||

| Property | Test method | Values | ||

| Physical | Longitudinal shrinkage | ASTM D 2671 | ≤5% | |

Tensile strength  |

ASTM D 2671 | ≥12 MPa | ||

| Breakdown elongation | ASTM D 2671 | ≥400% | ||

| Aging(175℃/168hrs) | Breakdown elongation | ASTM D 2671 | ≥400% | |

| Heat shock | ASTM D 2671 | No cracking | ||

| Low temperature flexibility(-55℃/4hrs) | ASTM D 2671 | No cracking | ||

| Electrical | Dielectric voltage Withstand | ASTM D 2671 | 2500V,60s No breakdown | |

| Volume resistivity | ASTM D 2671 | ≥10~14Ω.cm | ||

| Dielectric strength | ASTM D2671 | ≥25 KV/mm | ||

| Chemical | Flammability | ASTM D 2671 | Self-extinguish in 60s | |

| Copper corrosion | ASTM D2671 | No corrosion | ||

| Printing performance | SAE AS81531

MIL-STD-202 |

50 rubs, legible

30 strokes, legible |

||

| Fluids resistance (23℃/24hrs) | SAE AS81531 | Printing legible | ||

IDS-FR Fluid Resistant Heat Shrinkable Polyolefin Identification Sleeves

Features

*Cross linked polyolefin *Highly flame-retardant, Fluid resistant

*Excellent printing property, permanent identification.

*Excellent electrical, physical, chemical and printing properties.

*RoHS and REACH compliant * Operating temperature: -55~135 ℃

*Shrink temperature:120 ℃ *Shrink Ratio: 3:1

Standards

UL224 125℃ 600V SAE AMS-DTL-23053/5 SAE AS 81531,MIL-STD-202

| Dimensions | |||

| Reference | As supplied(mm) | After recovered(mm) | Size for conductor |

| UPM IDS-FR | ID min. | ID max. | mm |

| 2.4 | 2.4 | 0.8 | 0.9-2.0 |

| 3.2 | 3.2 | 1.1 | 1.1-2.7 |

| 4.8 | 4.8 | 1.6 | 1.8-4.1 |

| 6.4 | 6.4 | 2.1 | 2.3-5.5 |

| 9.5 | 9.5 | 3.2 | 3.5-8.1 |

| 12.7 | 12.7 | 4.2 | 4.6-10.8 |

| 19.1 | 19.1 | 6.3 | 7.0-16.3 |

| 25.4 | 25.4 | 8.5 | 9.3-21.6 |

| Technical Data | ||||

| Property | Test method | Values | ||

| Physical | Longitudinal shrinkage | ASTM D 2671 | ≤5% | |

Tensile strength  |

ASTM D 2671 | ≥13 MPa | ||

| Breakdown elongation | ASTM D 2671 | ≥400% | ||

| Aging(175℃/168hrs) | Breakdown elongation | ASTM D 2671 | ≥300% | |

| Heat shock | ASTM D 2671 | No cracking | ||

| Low temperature flexibility(-55℃/4hrs) | ASTM D 2671 | No cracking | ||

| Electrical | Dielectric voltage Withstand | ASTM D 2671 | 2500V,60s No breakdown | |

| Volume resistivity | ASTM D 2671 | ≥10~14Ω.cm | ||

| Dielectric strength | ASTM D2671 | ≥25 KV/mm | ||

| Chemical | Flammability | ASTM D 2671 | Self-extinguish in 15s | |

| Copper corrosion | ASTM D2671 | No corrosion | ||

| Printing performance | SAE AS81531

MIL-STD-202 |

50 rubs, legible

30 strokes, legible |

||

| Fluids resistance (23℃/24hrs) | SAE AS81531 | Printing legible | ||

IDS-HT225 Military Grade High-temperature Resistant Heat Shrinkable Identification Sleeves

Features

*Cross linked fluoropolymer *Highly flame-retardant, Fluid resistant

*Excellent printing property, permanent identification

*Excellent electrical, physical, chemical properties

*High continuous operating temperature.

*Operating temperature: -55~225 ℃

*Shrink temperature:200 ℃ *Shrink Ratio:2:1

*Military grade *RoHS and REACH compliant

Standards

SAE AS 81531 MIL-STD-202

| Dimensions | |||

| Reference | As supplied(mm) | After recovered(mm) | Size for conductor |

| UPM IDS-HT225 | ID min. | ID max. | mm |

| 2.4 | 2.4 | 0.8 | 0.8-2.0 |

| 3.2 | 3.2 | 1.6 | 1.7-2.7 |

| 4.8 | 4.8 | 2.4 | 2.5-4.5 |

| 6.4 | 6.4 | 3.2 | 3.4-6.0 |

| 9.5 | 9.5 | 4.8 | 5.0-9.0 |

| 12.7 | 12.7 | 6.4 | 6.6-12.0 |

| 19.1 | 19.1 | 9.5 | 9.9-18.5 |

| 25.4 | 25.4 | 12.7 | 13.0-24.5 |

| 38.1 | 38.1 | 19.1 | 21.0-37.0 |

| 50.8 | 50.8 | 25.4 | 27.0-48.0 |

| Technical Data | ||||

| Property | Test method | Values | ||

| Physical | Longitudinal shrinkage | ASTM D 2671 | ≤5% | |

Tensile strength  |

ASTM D 2671 | ≥24 MPa | ||

| Breakdown elongation | ASTM D 2671 | ≥300% | ||

| Aging(225℃/168hrs) | Breakdown elongation | ASTM D 2671 | ≥200% | |

| Heat shock(275℃/4hrs) | ASTM D 2671 | No cracking | ||

| Low temperature flexibility(-55℃/4hrs) | ASTM D 2671 | No cracking | ||

| Electrical | Dielectric voltage Withstand | ASTM D 2671 | 2500V,60s No breakdown | |

| Volume resistivity | ASTM D 2671 | ≥10~12Ω.cm | ||

| Chemical | Flammability | ASTM D 2671 | Self-extinguish in 15s | |

| Copper corrosion | ASTM D2671 | No corrosion | ||

| Printing performance | SAE AS81531

MIL-STD-202 |

100 rubs, legible

100 strokes, legible |

||

| Fluids resistance (23℃/24hrs) | SAE AS81531 | Printing legible | ||

Typical application

*Suitable for high performance identification of wire and cables in high temperature applications of industry, military,aerospace or where extreme resistance to fuels, lubricants and cleaning solvents is required.

Member Information

| Union Polymer Material Co.,ltd | |

|---|---|

| Country/Region: | Liao Ning - China |

| Business Nature: | Manufacturer |

| Phone: | 15940969469 |

| Contact: | Lily Zhang (Sales Manager of L.V) |

| Last Online: | 06 Dec, 2024 |