| Model: | MT-B003 |

|---|---|

| Brand: | Mitr |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Metal Mineral |

| Label: | alumina beads , ball mill media , milling ball |

| Price: |

US $6

/ kilo

|

| Min. Order: | 1 kilo |

Product Description

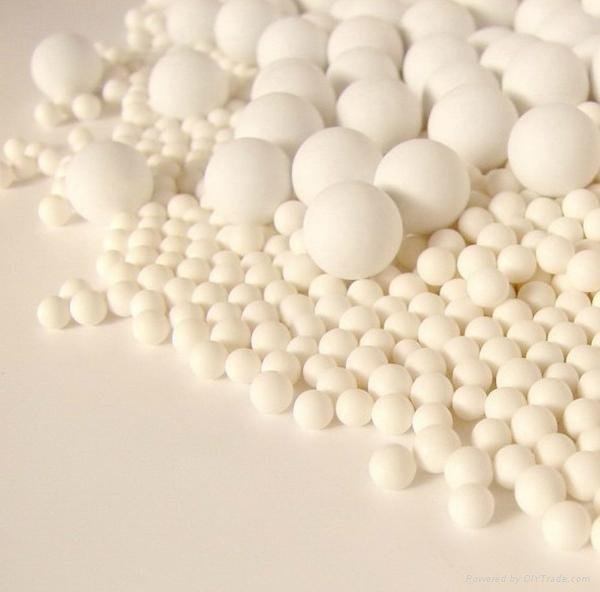

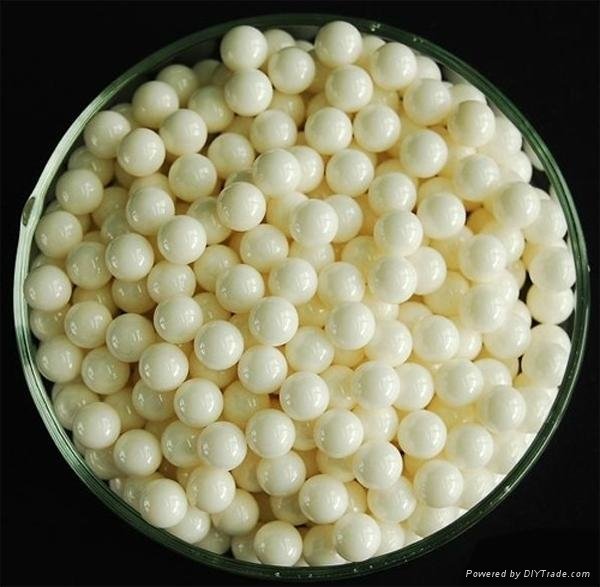

Alumina Ceramic Grinding Media Balls

Mitr alumina oxide ball Simple Introduction:

1 Good restitance and high strength, while testing rare earth material, it can ensure the abraded material is not mixed with other impurities.

2 With high hardness, high strength, high toughness, high wear resistance and chemical resistance, has been range used in ceramics, refractories, mechanical, electronic, optical, optical fiber communication, clock jewelry, aerospace, biology, chemistry, etc. widely applied in various fields.

3 Pure zirconia is a high refractory material, while the melting temperature achieved 2900 °C it improves the high temperature viscosity of the glaze and expanded temperature range of viscosity, has good thermal stability.

alumina oxide ball specification:

Size: 2mm~30mm or can be customized

Compared with steel ball, ceramic ball has following advantages:

1. 59% lighter than steel ball, which means less centrifugal force and less wear on the groove during high speed and acceleration.

2. 44% larger elastic modulus, which means less deformation under load

3. Harder with Rockwell hardness as 78

4. Smaller friction coefficient

5. Only 1/4 coefficient of thermal expansion of steel, can endure sharp fluctuation of temperature

6. Superior surface finish can be achieved, Ra could be 4~6 nm

7. Can endure high temperature with high hardness and strength up to 1050°C

8. Never rust, and can roll without lubrication.

9. More corrosion resistant than steel.

10. Free of metal contamination.

11. Non-magnetic

12. Electric isolation

13. No adhesive-wear with metal

14. Contact angular is very large with molten and nearly no reaction

Mitr alumina oxide ball Images:

alumina oxide ball application:

The ceramic grinding ball has been used widely used as supporting material at the reactor bottom in petrochemical, in ball mills, pot mill, vibrating mill and other fine grinding plants as abrasive media for ceramic raw materials and glaze materials in ceramic, cement, glass, porcelain enamel, paints, pigments, chemicals, pharmaceuticals, paint industry, inks, cosmetics, inorganic mineral powders, fine chemical, coal-chemical, fertilizer, natural gas and environmental protection industries . etc.

Packaging & Shipping

alumina oxide ball Packaging:

plastic bag + foam pad + wooden case

Company Information

Changsha Mitr Instrument And Equipment Corporation

Our factory was founded in 2007 which is principally engaged in manufacturering and developmenting experimental equipments, and providing related technical advisory services .Our main products are acrylic glove boxes,planeatry ball mills and mill jars. Our enterprise’s spirit is "excellence in mind ,seiko to type".

We rely on strong technology with Central South University--the Key Laboratory of Powder Metallurgy in China. Besides, we have a strong R&D and production team:7 senior engineer,6 senior technicians and 4 engineers .In additon to that,our factory maintains long-term and close technical exchanges with Hunan University, Shanghai Jiaotong University and other famous universities.

Member Information

| Changsha Mitr Instrument and Equipment Co., Ltd | |

|---|---|

| Country/Region: | Hu Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15581610191 |

| Contact: | Myra (sales) |

| Last Online: | 14 May, 2014 |