| Model: | plastic moulds |

|---|---|

| Brand: | Haiyan Mould |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

| Label: | auto interior parts , auto exterior parts , plastic moulds |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

- Company Profile

Zhejiang Haiyan Mould Co., Ltd is located in Huangyan, Zhejiang, China, established in 1990,it is specialized in automotive part moulds, daily use product moulds, home appliances moulds and plastic parts.

Haiyan Mould occupies about 16500 square meters, with more than 160 staffs, including 25 experienced engineers, 80 skilled tool makers. HASCO, DME & LKM standards are adopted for different customer requirements, and CAD/CAM/CAE systems have already been used to strengthen our technical advantage.

During about 20 years development, Haiyan Mould has set its own mould standards and strict mould manufacturing process, each mould is run as project management, followed up by particular experienced engineer. 6S management system has been adopted for many years, Haiyan mould is also ISO9001 certified.

Adhere to the key concept of “Innovation and Constant Improvement ”, based on the group work which we paid higher attention to, Haiyan Mould has established long-term business cooperation with customers from Germany, USA, UK, France, Italy and Taiwan.

-

Working Step

|

1.R&D |

R&D support with early involvement. |

|

↓ |

|

|

2.Negotiation |

The quality, price, material, delivery time, payment item, ect. |

|

↓ |

|

|

3.Place an order |

According to your own design or you chooses our design. |

|

↓ |

|

|

4. Mould |

According to customer's request to build the moulds. Before make the mould, we send mould design to customer approval first, before move forward to production; we send samples to customer to confirm first. |

|

↓ |

|

|

5. Sample shot |

If the first sample come out is not satisfied, we modify the mould and until meet customer‘s satisfactory. |

|

↓ |

|

|

6. Delivery |

By sea or by air, according to customer's requirement. |

• Mould Pictures and Sample Pictures

Cavity

Pls contact us for more information.

Core

Pls contact us for more information.

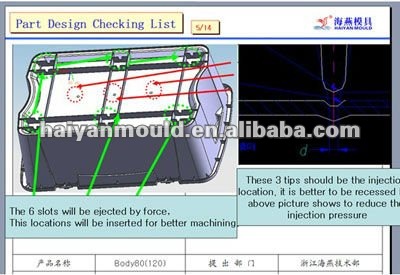

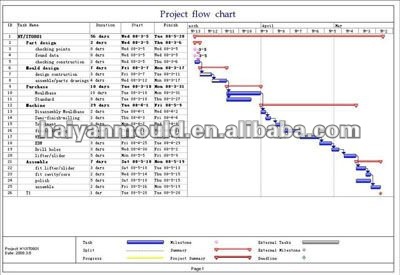

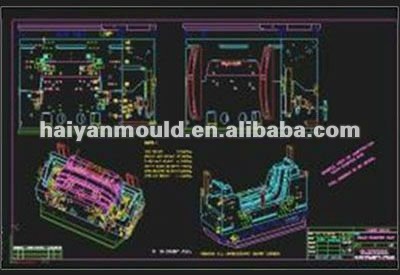

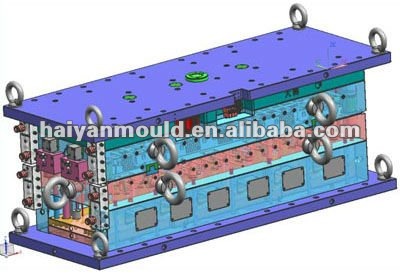

• Quality Control during Production Processing

1. Part Design Checking

2. Flow Analysis

3. Production Schedule & Follow Up

4. Mould 2D Design & Plan

5. Mould 3D Design

6. Mould Design Audit

7. Mould & Component Check

8. Troubleshoot and Solution during Mould testing

9. Quarterly Summary

• Standard Packing

Standard Appearance

Water proof and anti-dust

Plywood box (fumigation-free)

• The Document/Spare Parts offered when Delivery

3D Mould Drawings

2D Mould Assembly Drawings

Spare Part List

Record of Mould Testing Parameter

Mould Operation Manual (Optional)

Pls contact us for more information.

Member Information

| Zhejiang Haiyanmould Co., Ltd. | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 84616806 |

| Contact: | Mr. Gao (sales manager) |

| Last Online: | 11 May, 2015 |