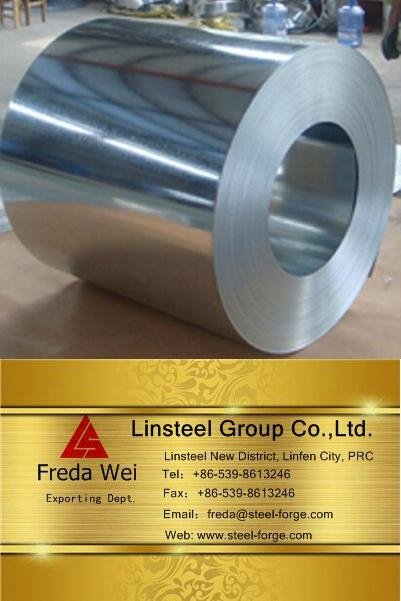

| Model: | GI |

|---|---|

| Brand: | Linsteel |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Flat & Rolled Metallic Materials |

| Label: | galvanized coil , prepainted coil , steel coil |

| Price: |

US $570

/ Ton

|

| Min. Order: | 20 Ton |

Product Description

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The technical informations above respond to the extreme feasibilities of Aahana International's installations. Some extreme combinations may not be available. It is therefore recommended to consult us in these cases when specific dimentions, packaging, finishing etc. are requested. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Technical Data Sheet |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

This is hot or cold-rolled steel with a zinc coating applied by a continuous hot-dip galvanising process, which gives excellent corrosion resistance and very good formability.

It is produced with a very wide range of qualities: mild steels for bending and drawing, structural steels, and steels with a very high yield strength.

It is available as sheet or coiled steel in thicknesses from 0.20mm to 6.35mm and widths from 80cm to 188cm depending on the substrate used.

Coating thicknesses range from Z100 to Z350.

It is joined by welding, clinching or adhesive bonding.

Options: Surface appearance, finished surface, passivation, oiling.

Can be protected by a thin dry organic film.

Properties

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin-passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantages

Hot dip galvanised products offer excellent corrosion resistance combined with very good forming properties. The coating process can apply very thick zinc layers, up to 725 g/m?(total of both sides).

Applications

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Recommendations for use

Storage

Galvanised strips are usually supplied passivated or oiled to temporarily limit any risk of white rust formation. During transport and storage, all necessary precautions must be taken to keep the material dry and to prevent the formation of condensation. Improved protection can be achieved by the application of an Easyfilm® thin organic coating (please see data sheet E80 for the specific properties of Easyfilm®).

Forming and joining

The forming and joining techniques currently used for uncoated steel are also suitable for galvanised steel.

It is essential to select a coating thickness that is compatible with the forming and joining processes envisaged, without compromising the desired degree of corrosion protection.

Painting

Hot dip galvanised steels can be painted after degreasing and surface treatment when supplied oiled. If an Easyfilm® thin organic coating has been applied, they can be painted directly, without any prior surface treatment. However, the paint must be compatible with the Easyfilm® resin.

Weldability

In electrical resistance welding, the welding current must be suitably regulated and regularly adjusted. Electrode life can be extended by regularly stepping up the welding current and periodically dressing (machining) the electrodes.

| Price Terms: | FOB Qingdao |

|---|---|

| Payment Terms: | TT/LC |

| Packing: | Exporting Package Standard |

| Lead Time: | Within 20 days |

Member Information

| Linsteel Group Co.,Ltd | |

|---|---|

| Country/Region: | Shan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 18300438702 |

| Contact: | Chris (Saler) |

| Last Online: | 26 Jun, 2014 |

Related Products of this Company

-

Compeitive price PPGI & PPGL galvanized

US $560

-

Galvanized Steel Coil

US $550

-

PPGI prepainted galvanized color coated

US $540

-

Price hot dipped galvanized steel coil

US $560

-

Hot dip galvanized prepainted steel

US $520

-

Color Coated Steel Coil

US $600

-

Hot dip galvanized prepainted steel coil

US $560

-

PrePainted Hot Dip 55% Al-Zn Coated

US $540

-

Hot Dipped Galvanized Steel Coil

US $560

-

PPGI/ PPGL Steel Coil

US $580