| Model: | TSSK 75 |

|---|---|

| Brand: | Purui |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | PET flakes recycling , plastic recycling , PET pelletizer |

| Price: |

US $70000

/ pc

|

| Min. Order: | 1 pc |

Product Description

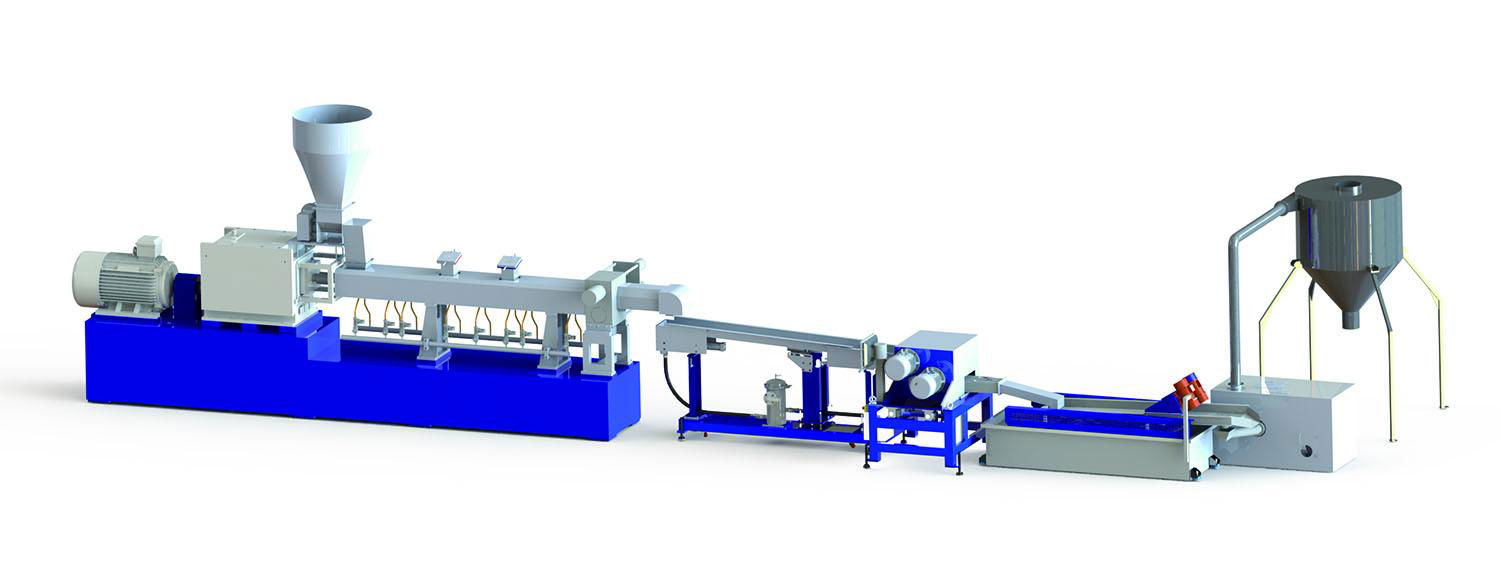

PET bottle flakes pelletizing line recyclin gmachine pelletizing machine

Co-rotating Twin –Screw Extruder

1.Type:

High torque co-rotation twin screw extruder

2. Advantage:

a. Cylinder

Hard alloy steel sleeve

Watercourse optimized

With degassing exhauting design

Anti-returens

Side feeding

High efficiency

b. Screw element

Hard alloy steel

Screw thread curve optmized

Involute spline joint

Self-cleaning

Anti wearing

Double head and triple head available

C. Gear box

High torque desigh

Import international bearing

Lubrication full infusion lubrication

Application:

It is widely applied in the filling, blend, modifying, strengthening of rubber-plastic and engineering resins, and the chloridizing of PP and Devolatilizing of the Superabsorbent resins. It can also be used in Masterbatch degradation, Polyurethane poly addition reaction extrusion; PET flake recycling etc.

PET flakes recycling

PET flakes will be mixed and dried with the double disc, with the help of vaccum degassing system during extrusion make sure the IV drops little, IV,0.03. Thanks to the underwater strand pelletizing system and PLC control, it can be automatically control.

1.Filling modification

Caco3

Talcum powder

Baso4

TiO2

Ceramic powder

Wood flour/plant fiber

Other inorganic filler

2.Reinforce modification

Short glass fiber

Long glass fiber

Carbon fiber

Other whisker

3.preparation of master batch

Carbon black master batch

Color master batch

Flame-retardant master-batch

Degradation master batch

Other special functions master-batch

4.Blending modification

Thermoplastic material/ Elastomer

Polymer Alloys

5. Cable material

PVC cable material

Zero halogen cable material

PE TR-XLPE, NDH

PE cross-linking cable material

Special cable material

Mode of Cutting:

Strand pelletizing

Water-ring rubs surface pelletizing

Wind-cooling rubs surface pelletizing

Underwater pelletizing

Model

Technical parameter of TSSK normal co-rotating twin screw extruder

| Model | TSSK 20 | TSSK 30 | TSSK 35 | TSSK-50 | TSSK-65 | TSSK 75 | TSSK92 |

| Screw diameter(mm) | 30 | 45 | 65 | 90 | 100 | 120 | 150 |

| L/D | 18-24 | 18-24 | 18-24 | 18-24 | 18-24 | 18-24 | 18-24 |

| Screw Rotary Speed(R/min) | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 | 10-150 |

| Output(KG/H) | 2-40 | 10-60 | 100-150 | 150-250 | 250-350 | 300-600 | 400-750 |

Technical parameter High torque TSSK co-rotating twin screw extruder

| Screw dimater (mm) | 50.5 | 62.4 | 71.2 | 71.2 |

| Rotary speed | 500/600 | 500/600 | 500/600 | 500/600 |

| Main motor power | 55/75 | 90/110 | 132/160 | 200/250 |

| L/D | 28-48 | 28/48 | 28-48 | 28-48 |

| Capacity | 120-280 | 180-400 | 250-650 | 500-1200 |

Company

Chengdu purui polymer engineering co., ltd established in 2006 with the same investor in the Zhangjiagang city purui plsatic&rubber machinery Co.,ltd. We insist on and improve the plastic recycling machines, such as the plastic washing line, plastic pelletizing line with advanced technology and high responsibility to our customers. We thanks for customers all over the world trust and makes our company grow and develop. In the near future we will continue to do our best to solve customers plastic recycling problems.

Member Information

| chengdu purui polymer engineering co., ltd | |

|---|---|

| Country/Region: | Si chuan - China |

| Business Nature: | Manufacturer |

| Phone: | 15602292676 |

| Contact: | Aileen he (Sales manager) |

| Last Online: | 17 May, 2024 |

Related Products of this Company

-

Forced feed plastic recycling machine

US $120000

-

TSSK Co-rotating Twin screw extruder

US $40000

-

two stage plastic film recycling

US $60000

-

Baby mother extruder plastic recycling

US $130000

-

Single shaft shredder plastic shredder

US $20000

-

SJ single screw extruder rigid plastic

US $60000

-

Plastic washing line PP PE film washing

US $200000

-

Plastic heavy printed film and bags

US $80000

-

SIngle extruder plastic pelletizing line

US $80000

-

PP woven bags ton bags washing lines

US $80000