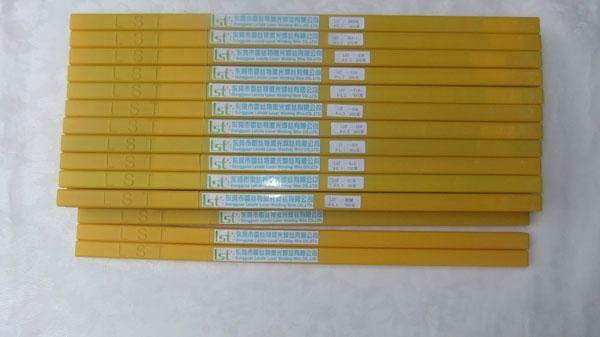

| Model: | LST/L30 |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Flat & Rolled Metallic Materials |

| Label: | plastic injection , heat-resisitant , mold |

| Price: |

¥1

/ pc

|

| Min. Order: | 10 pc |

Product Description

Range of Application: Applies to plastic mold steel with high tenacity, such as plastic injection mold, heat-resistant mold and corrosion-proof mold which exhibit excellent tooling quality and creping feature, and will have smooth and bright surface after abrading. It can meet the needs of dies which require higher polishing performance, such as varieties of hardware work pieces.

- Standard Evaluation: the models of parent material (base material) include:

- PDS3 NAK80 HPM38 G-STAR SUS440C P20-M P21 168 618 718 635 1.2311 1.2738 1.2083 1.2316 NIMAX UNIMAX

Chemical Compositions %

|

C |

Si |

Mn |

P |

S |

CR |

AL |

CU |

TI |

|

0.700 |

0.54 |

1.89 |

0.009 |

0.003 |

0.01 |

0.070 |

G0.191 |

0.168 |

The chemical compositions of re-melt deposit materials depend on practical welding parameters.

Hardness 37-42 HRC

The hardness of re-melt deposit materials mainly depends on parent materials and its chemical compositions. But these influencing factors will decrease with the increase of welding layers. p;aH'� @� 5.4pt 0cm 5.4pt'>

4.05

The chemical compositions of re-melt deposit materials depend on practical welding parameters.

Hardness 42-47 HRC

The hardness of re-melt deposit materials mainly depends on parent materials and its chemical compositions. But these influencing factors will decrease with the increase of welding layers.

Member Information

| Layst Laser Welding Wire (HK) Co., Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13929267911 |

| Contact: | Lei Sheng (Marketing Manager) |

| Last Online: | 23 Jul, 2014 |