| Model: | S3 |

|---|---|

| Brand: | UPM Heat Shrink |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Insulation Material |

| Label: | heat shrink , shipbuilding , cable mark |

| Price: |

-

|

| Min. Order: | 100 pc |

Product Description

UPM S3 Flame Retardant Medium Wall Heat Shrink Tube

Features: Features: |

||

Medium wall cross-linked polyolefin Medium wall cross-linked polyolefin |

Flame retardant (VW-1) Flame retardant (VW-1) |

|

Excellent electrical,sealing, mechanical properties Excellent electrical,sealing, mechanical properties |

Thermal melt adhesive liner; Thermal melt adhesive liner; |

|

Shrink ratio: 3:1; Shrink ratio: 3:1; |

RoHS compliant . RoHS compliant . |

|

|

|

||

DNV; DNV; |

CCS; CCS; |

|

Typical application: Typical application: |

||

Ideal for outdoor electrical equipment and connections in wet and underground environments,such as marine vessels,off-shore oil platform, shipyard and harbor ; Ideal for outdoor electrical equipment and connections in wet and underground environments,such as marine vessels,off-shore oil platform, shipyard and harbor ; |

||

Suitable for easy identification of cable polarity and troubleshooting. Suitable for easy identification of cable polarity and troubleshooting. |

||

Dimensions: Dimensions: |

||

Shrink Ratio 3:1

| Reference | As supplied(mm) | After recovered(mm) | Standard length | |

| UPM S3 | ID min. | ID max. | WT nom. | m |

| 8/2 | 8 | 2 | 2.0 | 1.22 |

| 9/3 | 9 | 3 | 2.0 | 1.22 |

| 12/4 | 12 | 4 | 2.0 | 1.22 |

| 16/5 | 16 | 5 | 2.2 | 1.22 |

| 19/6 | 19 | 6 | 2.5 | 1.22 |

| 22/6 | 22 | 6 | 2.5 | 1.22 |

| 25/8 | 25 | 8 | 2.5 | 1.22 |

| 28/6 | 28 | 6 | 2.5 | 1.22 |

| 33/8 | 33 | 8 | 2.5 | 1.22 |

| 35/12 | 35 | 12 | 2.5 | 1.22 |

| 40/12 | 40 | 12 | 2.5 | 1.22 |

| 45/13 | 45 | 13 | 2.5 | 1.22 |

| 55/16 | 55 | 16 | 2.7 | 1.22 |

| 65/19 | 65 | 19 | 2.8 | 1.22 |

| 75/22 | 75 | 22 | 3.0 | 1.22 |

| 85/25 | 85 | 25 | 3.0 | 1.22 |

| 95/25 | 95 | 25 | 3.0 | 1.22 |

| 115/34 | 115 | 34 | 3.0 | 1.22 |

| 130/36 | 130 | 36 | 3.0 | 1.22 |

| 140/42 | 140 | 42 | 3.0 | 1.22 |

| 160/50 | 160 | 50 | 3.0 | 1.22 |

| 175/58 | 175 | 58 | 3.0 | 1.22 |

| 200/65 | 200 | 65 | 3.0 | 1.22 |

| 230/75 | 230 | 75 | 3.0 | 1.22 |

| 260/85 | 260 | 85 | 3.0 | 1.22 |

UPM S11 Green/Yellow Heat Shrink Sleeve for Wire/Cable Mark

Features: Features: |

||

Cross linked polyolefin; Cross linked polyolefin; |

Co-extrusion of Green/Yellow stripped color; Co-extrusion of Green/Yellow stripped color; |

|

Flame retardant ; Flame retardant ; |

Excellent Flexibility Excellent Flexibility |

|

Tube with adhesive linner available; Tube with adhesive linner available; |

RoHS compliant RoHS compliant |

|

Voltage Class:1000 V Voltage Class:1000 V |

Shrink Ratio:2:1 & 3:1 Shrink Ratio:2:1 & 3:1 |

|

Typical application: Typical application: |

||

General purpose insulation of wire/cable jacket General purpose insulation of wire/cable jacket |

||

Widely used in wire bundles or cables to Line identification Widely used in wire bundles or cables to Line identification |

||

Cross reference: Cross reference: |

||

Raychem/Tyco : DCPT 2:1 Raychem/Tyco : DCPT 2:1 |

||

Dimensions

Dimensions

| Reference | As supplied(mm) | After recovered(mm) | Standard length | |

| UPM S11 | ID min. | ID max. | WT nom. | m |

| Single wall shrink ratio: 2:1 | ||||

| 2.0/1.0 | 2.0 | 1.0 | 0.35 | 200 |

| 3.0/1.5 | 3.0 | 1.5 | 0.38 | 200 |

| 4.0/2.0 | 4.0 | 2.0 | 0.45 | 100 |

| 5.0/2.5 | 5.0 | 2.5 | 0.45 | 100 |

| 6.0/3.0 | 6.0 | 3.0 | 0.50 | 100 |

| 8.0/4.0 | 8.0 | 4.0 | 0.55 | 100 |

| 10.0/5.0 | 10.0 | 5.0 | 0.55 | 100 |

| 12.0/6.0 | 12.0 | 6.0 | 0.60 | 100 |

| 16.0/8.0 | 16.0 | 8.0 | 0.70 | 100 |

| 18.0/9.0 | 18.0 | 9.0 | 0.70 | 100 |

| 20.0/10.0 | 20.0 | 10.0 | 0.75 | 100 |

| 25.0/12.5 | 25.0 | 12.5 | 0.90 | 50 |

| 30.0/15.0 | 30.0 | 15.0 | 0.95 | 50 |

| 35.0/17.5 | 35.0 | 17.5 | 0.95 | 50 |

| 40.0/20.0 | 40.0 | 20.0 | 1.00 | 50 |

| 50.0/25.0 | 50.0 | 25.0 | 1.00 | 25 |

| 60.0/30.0 | 60.0 | 30.0 | 1.10 | 25 |

| 70.0/35.0 | 70.0 | 35.0 | 1.20 | 25 |

| 80.0/40.0 | 80.0 | 40.0 | 1.30 | 25 |

| 100.0/50.0 | 100.0 | 50.0 | 1.65 | 25 |

| Reference | As supplied(mm) | After recovered | Standard length |

| UPM S11 | ID min. | ID max.(mm) | m |

| Single wall shrink ratio 3:1 | |||

| 3/1 | 3.0 | 1.0 | 200 |

| 6/2 | 6.0 | 2.0 | 100 |

| 9/3 | 9.0 | 3.0 | 100 |

| 12/4 | 12.0 | 4.0 | 100 |

| 18/6 | 18.0 | 6.0 | 100 |

| 24/8 | 24.0 | 8.0 | 50 |

| 39/13 | 39.0 | 13.0 | 50 |

| Dual wall (with adhesive liner) shrink ratio 3:1 | |||

| 12/4 | 12.0 | 4.0 | 1.22 |

| 18/6 | 18.0 | 6.0 | 1.22 |

| 24/8 | 24.0 | 8.0 | 1.22 |

| 39/13 | 39.0 | 13.0 | 1.22 |

UPM YHRSMST/A Heat Shrinkable Molded Parts

Features: Features: |

||

Cross-linked semi-rigid polyolefin with adhesive liner ; Cross-linked semi-rigid polyolefin with adhesive liner ; |

Excellent electrical insualtion and strain relief ; Excellent electrical insualtion and strain relief ; |

|

Sealing/ Mechanical protection; Sealing/ Mechanical protection; |

Shrink ratio: 4:1 at small end Shrink ratio: 4:1 at small end |

|

Flame retardant UL 224 VW-1; Flame retardant UL 224 VW-1; |

RoHS compliant. RoHS compliant. |

|

Approvals: Approvals: |

||

China Classification Society (CCS). China Classification Society (CCS). |

||

Typical application: Typical application: |

||

Ideal for strain relief and mechanical protection of connector and/or cable ; Ideal for strain relief and mechanical protection of connector and/or cable ; |

||

Suitable for outdoor electrical equipment and connections in wet and underground environments such as marine vessels, off-shore oil platforms, shipyard and harbor applications. Suitable for outdoor electrical equipment and connections in wet and underground environments such as marine vessels, off-shore oil platforms, shipyard and harbor applications. |

||

Dimensions: Dimensions: |

||

| Reference | Cross reference | As supplied (a )(mm) | After free recovered (b)(mm) | ||||||

| UPM YHRSMST/A | H | J | H | J | P±20% | R±20% | JO±20% | W±10% | |

| B0 | 202A111 | 16.5 | 16.5 | 8.5 | 4 | 25 | 14 | 6 | 1.5 |

| B1 | 202A121 | 24.6 | 24.6 | 10 | 6 | 35 | 20 | 10 | 1.6 |

| B2 | 202A132 | 28.4 | 28.4 | 15 | 7 | 50 | 25 | 15 | 1.8 |

| B3 | 202A142 | 31.0 | 31.0 | 19 | 8 | 65 | 35 | 20 | 1.8 |

| B4 | 202A153 | 36.1 | 36.1 | 23 | 9 | 90 | 45 | 35 | 1.8 |

| B5 | 202A163 | 42.7 | 42.7 | 29 | 10 | 100 | 55 | 35 | 2.0 |

| B6 | 202A174 | 60.0 | 60.0 | 38 | 16 | 120 | 60 | 40 | 3.3 |

| B7 | 202A185 | 66.0 | 66.0 | 45 | 20 | 135 | 80 | 40 | 3.3 |

| B8 | 202A196 | 86.4 | 86.4 | 59 | 28 | 170 | 95 | 55 | 3.3 |

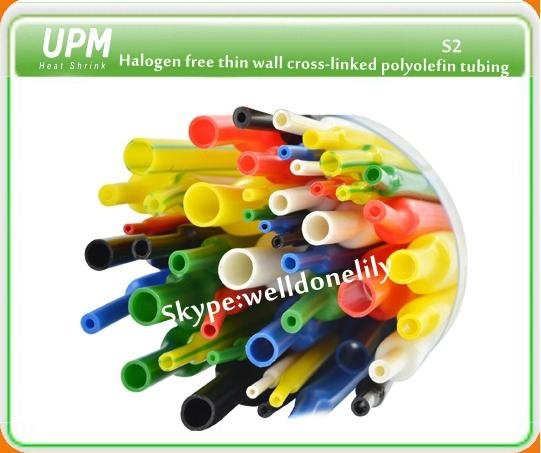

UPM Heat Shrink Thin Wall Tubing for General Purpose Insulation Protection

Features: Features: |

||

Insulation, Protection,Identification; Insulation, Protection,Identification; |

Flame retardant ; Flame retardant ; |

|

Halogen free, Flexible ; Halogen free, Flexible ; |

Wide range of colors ; Wide range of colors ; |

|

Shrink Ratio:2:1 & 3:1; Shrink Ratio:2:1 & 3:1; |

Voltage Class:600~1000 V. Voltage Class:600~1000 V. |

|

Typical application: Typical application: |

||

Ideal for electrical insulation,strain relief,wire bonding and light harness jacketing; Ideal for electrical insulation,strain relief,wire bonding and light harness jacketing; |

||

Common applications include electronic systems of subway, aircraft, submarine, control room facilities and sealed environment Common applications include electronic systems of subway, aircraft, submarine, control room facilities and sealed environment |

||

Approvals: Approvals: |

||

UL approval; UL approval; |

File No.: File No.: |

|

Cross reference: Cross reference: |

||

Raychem/Tyco : Versafit V2 / RNF-100. Raychem/Tyco : Versafit V2 / RNF-100. |

||

Dimensions

Dimensions

Shrink ratio 2:1

</</diyep:docbody>| Reference | As supplied ID (mm) | After recovered(mm) | Standard length | Reference | As supplied ID(mm) | After recovered(mm) | Standard length | ||

| UPM S2(n) | ID max. | WT | m/spool | UPM S2(n) | ID max. | WT | m/spool | ||

| 0.6 | 0.9±0.2 | 0.4 | 0.33±0.10 | 200 | 15.0 | 15.5±0.4 | 7.5 | 0.70±0.10 | 100 |

| 0.8 | 1.1±0.2 | 0.5 | 0.33±0.10 | 200 | 16.0 | 16.5±0.4 | 8.0 | 0.70±0.10 | 100 |

| 1.0 | 1.5±0.2 | 0.7 | 0.36±0.10 | 200 | 17.0 | 17.5±0.4 | 8.5 | 0.70±0.10 | 100 |

| 1.5 | 2.0±0.2 | 0.9 | 0.45±0.10 | 200 | 18.0 | 19.0±0.5 | 9.0 | 0.70±0.10 | 100 |

| 2.0 | 2.5±0.2 | 1.0 | 0.45±0.10 | 200 | 20.0 | 22.0±0.5 | 10.0 | 0.80±0.15 | 100 |

| 2.5 | 3.0±0.2 | 1.3 | 0.45±0.10 | 200 | 22.0 | 24.0±0.5 | 11.0 | 0.80±0.15 | 100 |

| 3.0 | 3.5±0.2 | 1.5 | 0.45±0.10 | 200 | 25.0 | 26.0±0.5 | 12.5 | 0.90±0.15 | 50 |

| 3.5 | 4.0±0.2 | 1.8 | 0.45±0.10 | 200 | 28.0 | 29.0±0.5 | 14.0 | 0.90±0.15 | 50 |

| 4.0 | 4.5±0.2 | 2.0 | 0.45±0.10 | 200 | 30.0 | 31.5±1.0 | 15.0 | 1.00±0.15 | 50 |

| 4.5 | 5.0±0.2 | 2.3 | 0.45±0.10 | 100 | 35.0 | 36.5±1.0 | 17.5 | 1.00±0.15 | 50 |

| 5.0 | 5.5±0.2 | 2.5 | 0.56±0.10 | 100 | 40.0 | 41.5±1.0 | 20.0 | 1.00±0.15 | |

Member Information

| Union Polymer Material Co.,ltd | |

|---|---|

| Country/Region: | Liao Ning - China |

| Business Nature: | Manufacturer |

| Phone: | 15940969469 |

| Contact: | Lily Zhang (Sales Manager of L.V) |

| Last Online: | 06 Dec, 2024 |

Related Products of this Company

-

Telecommunication heat shrink tubing

-

Low Voltage Bus Bar Tubing

US $3

-

Thin wall tubing

US $0.99

-

Heat shrinkage tube for automotive

US $0.5

-

Heat Shrinkable Cable Accessories

-

non-polyolefin heat shrink

-

Heat shrinkable Repair Sleeve

US $1

-

Telecommuniation heat shrink

US $4

-

EPDM Cold Shrink Tubing

US $4

-

High shrink ratio 6:1 shrink tubing