| Model: | DIR DISTILLATIO |

|---|---|

| Brand: | TONGRUI OIL DISTILLATION MACHINE |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | oil distillation , Vacuum Distillation , Oil Distilling Plant |

| Price: |

US $1

/ SET

|

| Min. Order: | 1 SET |

Product Description

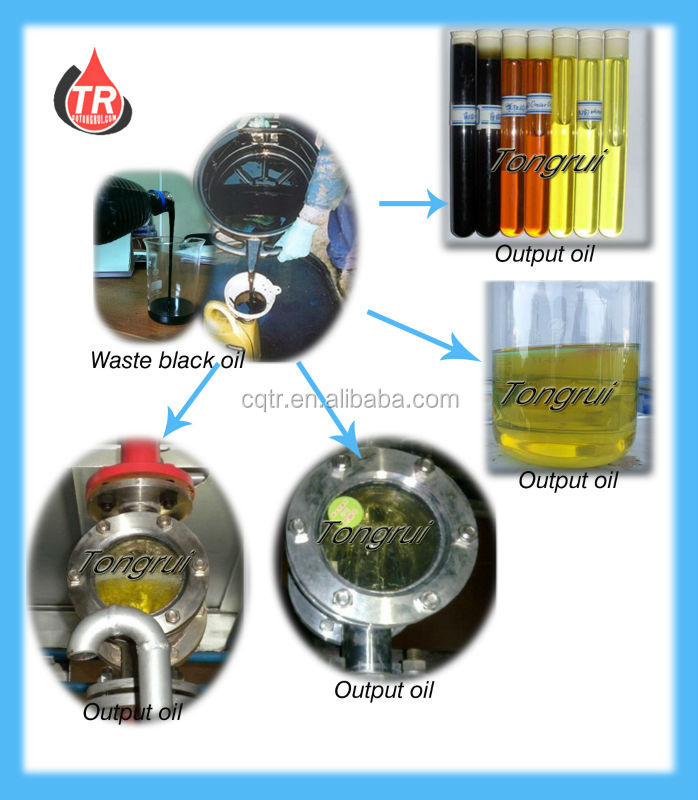

High Recovery Rate Black Engine Oil distllation Regeneration Equipment/Change Black Color to Golden Yellow

Distillation theory

This technology utilized catalyzing treatment during chemical processing. Our company developed a kind of composite catalyst, through catalyzing, the harmful substances are selectively processed, for example, polymerization, shielding, passivation effect and discharged as residues, so as to remove the unstable factors of the waste lubricating oil, make it became qualified lubricating base oil.

This technology is different from the traditional distillation process with sulfuric acid,it is also different from the current hydrogenation technology. The process of this technology is: Catalyzing treatment of waste lube oil (including gasoline engine oil,diesel engine oil ect. almost all sorts of recyclable waste oil), and then distill to new lube base oil. The oil will not mean to oxidate and change color, no odour. The residues can be used as fuel, it will not make secondary pollution. This technology is high automatic, the operation is simple, no complicate operation control, easy to learn and understand, low labour intensity, 1-2 persons are enough and no special requirement.

The used oil is mixed with catalyst in chemical treatment tank, then it is sent to distillation kettle to have it circulated and heated, while the temperature increasing, the oil gas is distilled out and cooled in to liquid through three stages cooling, they’re separately stored in water, gasoline/diesel, light lube oil, heavy lube oil receivers. The noncondensable gas will be sent to the furnace of boiler to have it burned and discharged after pass through waste gas disposer to ensure “zero “discharge of waste gas, The residues can be utilized as fuel to avoid pollution from it.

It’s easy to produce waste residue and bad smelling by traditional vitriol distilling, which will bring potential secondary pollution, moreover, it’s easy to change the color to black and produce the odor due to the recycled oil react with the oxygen. But after we use the alkaline complex catalyst refines the oil, the recycled oil havn’t change the color and havn’t create the odor. What’s more important, you can use the resid to be as the fuel to heating the oil, without any pollution. And the machine is easy to operate, only 1-2 workers can control the machine.

Features:

1. Easy to operate, low operation cost

2. Environmentally friendly, without secondary pollution.

3. The machine can recycle gasoline oil, diesel oil, engine oil, rubber oil and other lubricant oil to clean oil.

4. High quality refined oil, no any discoloration caused by oxidation, no any bad smelling.

5. Low cost contain:

1) only need the catalyst chemical, the cost is less thanUS$30 to refine one ton waste oil.

2) Heat consumption: 105kcal per ton waste oil

3) Power consumption: 40Kwh to recycle 1 ton waste oil

6. High degree of automation.

After-sales Services

One year guarantee for product quality. (People damaged parts are charged).

Lifelong maintenance and spare parts supply.

Free design of fixtures as customers required.

Free training for machines installation and operation of the staffs.

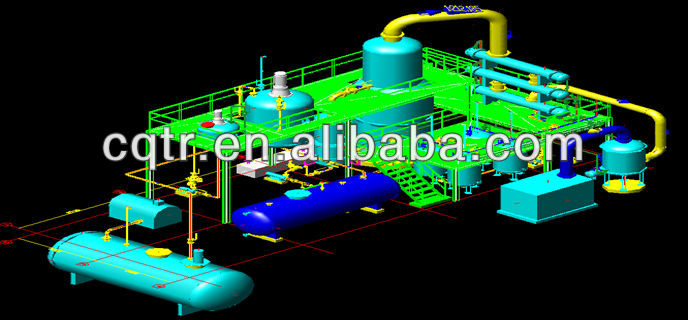

3D Model

DIR Questions and Answers

1)what is the difference between the absolute oil from waste oil and the original oil?The absolute oil from waste oil is SN250 base oil, lake of necessary additive.

2) How many liters absolute oil can be distilled from one ton waste oil 700L-800L

3)According to customers' requirements, our oil distillation plant can handle 1ton to 5tons per 10 hours and it can work 24hours.

4)If the machine got problem within one year(we guaranteed one year)

5)Will you company send technicist to Egypt to check?Who will be in charge of the cost of the air plain,hotel etc.?

If non-human factors, our company will charge.

6)How much is the chemical cost in one ton waste oil’s process.

The chemical cost: within 30 USD for one ton waste oil

Other Specifications for engine oil distillation purifiers

Final Engine oil

| Payment Terms: | T/T,L/C |

|---|---|

Member Information

| Chongqing Tongrui Filtration Equipment Manufacturing Co,Ltd | |

|---|---|

| Country/Region: | Chong Qin - China |

| Business Nature: | Manufacturer |

| Phone: | 15923000154 |

| Contact: | Marian Tan (Export sales manager) |

| Last Online: | 07 Aug, 2020 |