| Model: | AMC65 |

|---|---|

| Brand: | AMC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | fish food machine , fish feed line , fish food extruder |

| Price: |

US $9000

/ set

|

| Min. Order: | 1 set |

Product Description

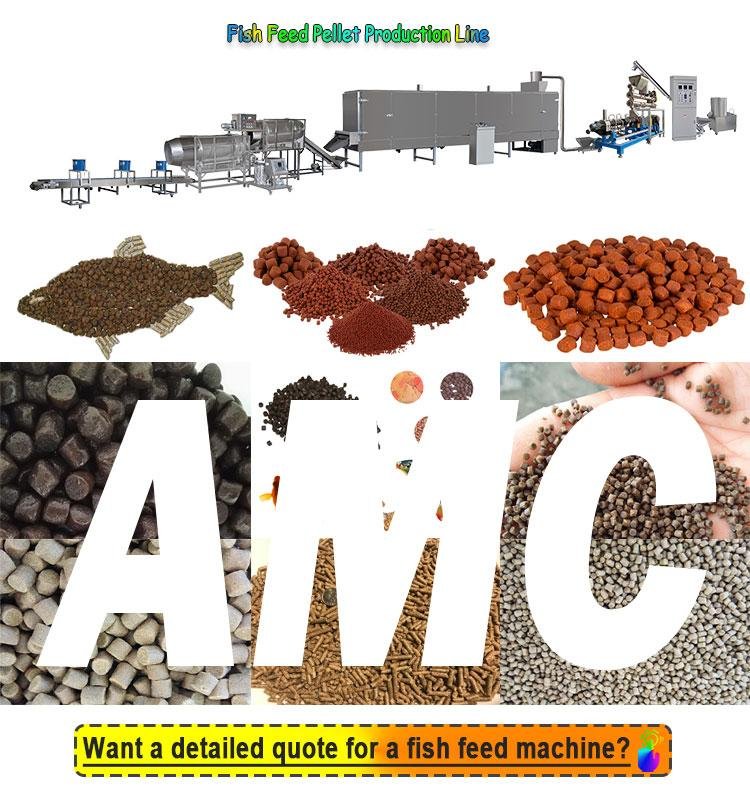

High protein high nutrition fish/feed food extrusion machines

1. Description:

Fish food machine is applied to produce the food with novel shape, particular taste and color, scientific nutrition combination catch up the trend of the market. In fish food processing line you will see the advanced technology of AMC machinery. With simple operation, accurate parameter control, the products can be finished in the stipulated temperature, pressure, humidity and time. Owing to the reasonable design, special materials, the stability, repairs can be guaranteed and ensured. The various shape and taste can meet the different requirements of the fish food.

a. Raw Materials: adopts corn flour, fish meal as raw materials

b. Products: different shapes are made by adjusting the dies from extruder

c. Capacity: 150kg/h, 240kg/h, 500kg/h, 1ton---3ton/h

d. Flow chart:

Mixing system---Extrusion system---Drying system---Flavoring system---Packing system

e. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

f. Machines Materials: All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

g. Technical Parameters:

|

Model |

Installed power |

Real power |

Output |

Dimension |

|

AMC65 |

70kw |

40kw |

100-150kg/h |

22000x1200x2200mm |

|

AMC70 |

90kw |

50kw |

200-240kg/h |

25000x1500x2200mm |

|

AMC85 |

120kw |

100kw |

400-500kg/h |

30000x3500x4300mm |

|

AMC90 |

135kw |

100kw |

800-1000kg/h |

30000x3500x4300mm |

|

AMC115 |

165kw |

115kw |

1000-2000kg/h |

30000x3500x4300mm |

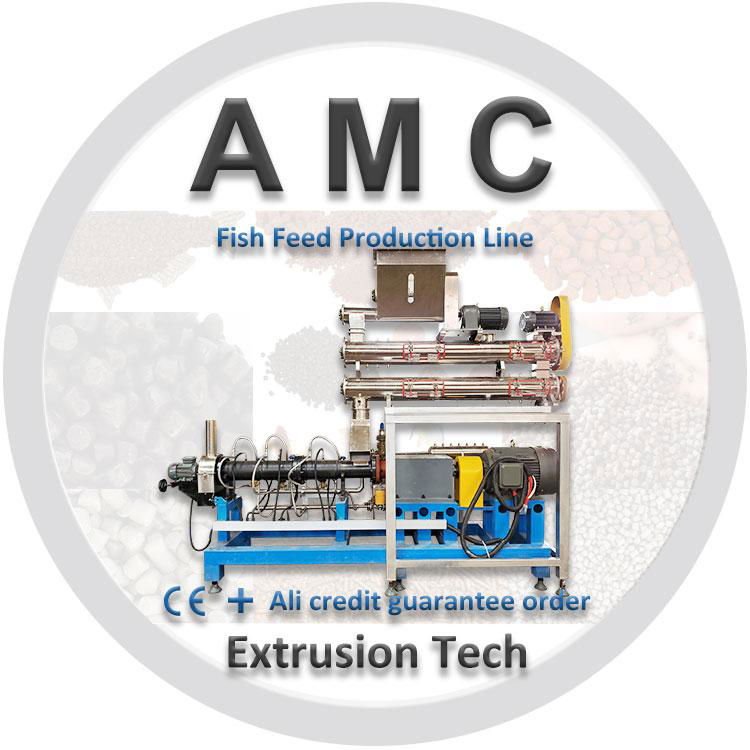

2. Features of Our Twin Screw Extruder:

A. Twin screw extruder with electricity heating system

a. The screws are made by alloy steel (38CrMoAL) and special craft by nitriding process, The HRC hardness is around 60---62, it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

b. The extrusion barrel is constructed of carbon steel, is made by #45 steel, stainless steel coating.

c. The gearbox has automatic lubrication function, with extends gear life.

d. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

e. SIEMENS(CHINA) brands electronic parts used in the controller box, make sure the extrusion process perfect.

f. Main Motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

B. Twin screw extruder with steam heating system ensures the most efficient, continuous and stable heating effects.

a. Big capacity feeding hopper, variable frequency speed, two stages mixing wings, fast and efficient mixing and feeding.

b. DDC Double axis differential conditioner, available for steam, Pre-cooking and high efficient.

c. Linear slide face cutting system, strong power, variable frequency speed and large output,

d. Unique designed square barrels, made by hard carbide sleeve, hard-wearing and durable.

e. Modular circular groove screws, available for different extrusion rate applications.

f. SIEMENS(CHINA) brands electronic apparatus used in the controller box, make sure the extrusion process perfect.

g. Main motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

3. Fish Food Made By Our Twin Screw Extruder

Our twin screw extruder can make fish food like Flake, Pellet, Tablet etc with various shapes and colors through changing the dies and formulas

We have full formula of foods and will guide you to use different materials to produce variety quality food.

4. High Reputation Among Our Customers

At present, Our Company locks in 70% market share in China, and our products have been selling well to more than 90 countries like Germany, Australia, Ukraine, Malaysia, Indonesia, Syria, Philippine, Thailand, Romania, South America, Middle East, Africa and other countries or regions.

We hope to establish good and long term friendly business relationship with more clients all over the world in the future.

4. Our Service

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free installation and commissioning of equipment until everything is functional;

4. Free management of equipments' long distance shipping;

5. Free training of equipment maintenance and operating personally;

6. Free new production techniques and formulas;

7. Provide 1 year complete warrantee and life-time maintenance service;

8. Engineers available to service machinery overseas.

9. Provide technical exchanging

10. Provide English Version of Installation/Operation/Service/Maintenance Manual

If you have any needs or enquiries, please feel free to contact us!

| Price Terms: | FOB Qingdao |

|---|---|

| Payment Terms: | TT/LC |

| Packing: | Wooden case |

| Lead Time: | 40days after receiving the downpayment |

Member Information

| Jinan Americhi Machinery & Equipment Co., Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 0086 18663764200 |

| Contact: | Chris (Director) |

| Last Online: | 18 Nov, 2024 |

Related Products of this Company

-

Textured Soy Protein Food Machine

US $72000

-

Nik naks machines

US $11000

-

Multipurpose Pulverizer/Milling/Grinding

US $3900

-

dog food making machine

US $10000

-

core filling snacks machine

US $9000

-

Fish Food Making Machine

US $68000

-

Floating fish food pellets machines

-

soya protein machines

US $30000

-

New corn puffs snacks machine

US $30000

-

Vertical Packaging Machine With