| Model: | EC1500S |

|---|---|

| Brand: | SUNPRING |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

| Label: | fish feed extruders , fish food machine , fish food extruder |

| Price: |

US $10000

/ set

|

| Min. Order: | 1 set |

Product Description

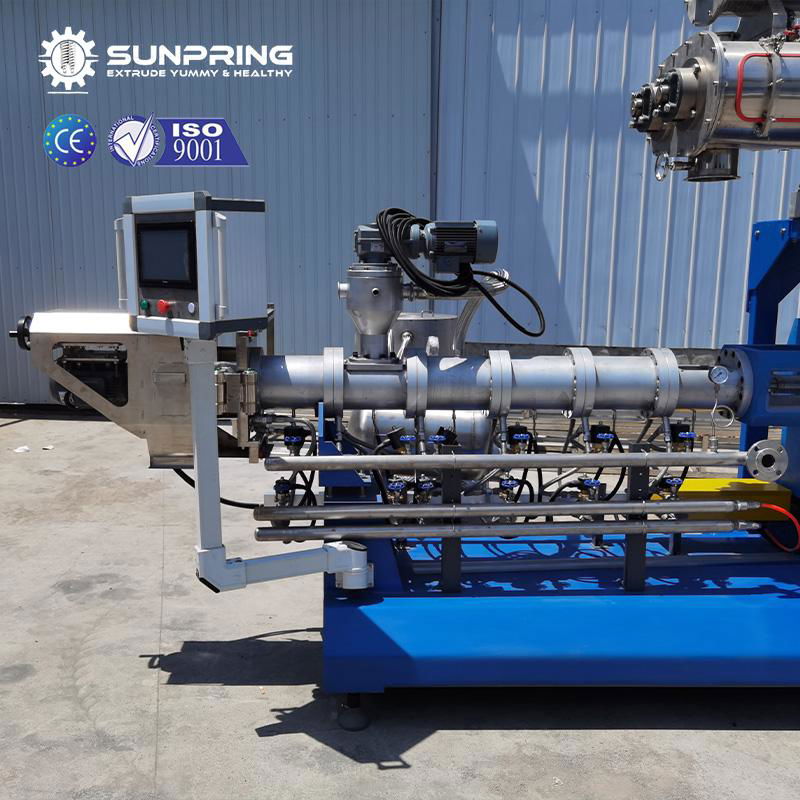

1. Fish Feed Extruder Description

Fish feed extruder manufacturers are mainly in Jinan city. The pet food is close to the human beings food in

the fine level, the health index and the nutritional ingredients,some of them request more highly than human

beings.

In extruder, the ingredients are cooked under intense heat and pressure as it moves toward the open end of the extruder where ingredients pass through a shaping die and knife. Dog food is dried in a multi-pass dryer until its moisture content is low enough to make it shelf stable. Dog food may pass through coating drum where animal fat and vitamins are applied onto dog food.

a. Raw Materials adopts wheat flour, rice flour, corn flour, defatted soy flour, fish meal and bone meal as raw materials

b. Products This line can be used to produce fish pellets, the pellets size can be from 1.0mm to 12.0mm by adjusting the dies from extruder; meanwhile it can produce dog food, cat food.

c. Capacity 150kg/h, 240kg/h, 500kg/h, 1ton/h-3ton/h

d. Flow chart mixing system---Extrusion system----Drying system----Flavoring system---Packing system

e. Voltage in China 380V/50Hz for three phases, 220V/50Hz for single phase, we can make it according to customers’ Local voltage according to different countries

f. Machines Materials

Machine Material: Stainless Steel #304, thickness:1.2mm

Main Motor: Siemens China brand

Main Electric elements: Siemens or CHNT brand

Inverter: Delta brand

g. Technical Parameters

|

Model |

Installed power |

Real power |

Output |

Dimension |

|

SP68 |

105kw |

76kw |

240-300kg/h |

24000x1500x2200mm |

|

SP88 |

171kw |

115kw |

400-500kg/h |

28000x3500x4300mm |

|

SP98 |

135kw |

100kw |

1-2ton/h |

30000x3500x4300mm |

|

SP128 |

165kw |

115kw |

3-5ton/h |

30000x3500x4300mm |

2.Twin screw extruder with steam heating system ensure the most efficient, continuous and stable

heating effects.

a. Big capacity feeding hopper, variable frequency speed, two stages mixing wings, fast and efficient mixing and feeding.

b. DDC Double axis differential conditioner, available for steam, Pre-cooking and high efficient.

c. Linear slide face cutting system, strong power, variable frequency speed and large output,

d. Unique designed square barrels, made by hard carbide sleeve, hard-wearing and durable.

e. Modular circular groove screws, available for different extrusion rate applications.

f. SIEMENS(CHINA) brands electronic apparatus used in the controller box, make sure the extrusion process perfect.

g. Main motor from SIEMENS(CHINA), ensure its powerful extrusion and excellent performance.

3. High Reputation Among Our Customers

At present, Our Company locks in 70% market share in China, and our products have been selling well to more than 90 countries like Germany, Australia, Ukraine, Malaysia, Indonesia, Syria, Philippine, Thailand, Romania, South America, Middle East, Africa and other countries or regions.

We hope to establish good and long term friendly business relationship with more clients all over the world in the future.

4. Provide Satisfied Service & Turnkey Project

Pre-sale services

1). Provide the free consultation of the equipment

2). Provide the standard device and the flow chart

3). According to the clients’ special requirement, offering the reasonable plan and free design helping to select the equipment.

4). Welcome to visit our factory or the domestic clients’ factory.

Services during the sales

1). Provide factory layout according to your factory size in advance.

2). Provide the basic formula

3). Inspect the machine before leaving the factory.

4). Oversea installation and commissioning the equipment.

5). Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to maintain machines during daily working.

6). Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide technology support with you forever.

After sale services

1). Provide the spare parts will at preferential price for an extended long time.

2). Provide technical exchanging

5. FAQ

|

MOQ |

1 set |

|

Supply Ability |

30 sets per quarter |

|

Shipping port |

Qingdao port, Shandong, China |

|

Packing details |

Fumigation-free wooden case outside, stretch film inner |

|

Relevant spare parts |

free, delivery with processing line |

|

Guarantee |

One year |

|

Oversea service |

Provide installation and commissioning |

|

Payment terms |

30% is paid by T/T as the down payment, 70% is paid by T/T or T/C before shipment. |

|

Delivery time |

40 days after receipt the deposit |

|

Pre-shipment |

When it finished, we will invite you to our company to inspect machines |

6. About Us

Jinan Sunpring Machinery & Equipment Co.,Ltd., is a professional food machinery manufacturer in China.

An exceptional engineering team, personal customer service center and high-quality manufacturing capabilities have evolved exponentially since our humble beginnings in 2004, making us one of the preeminent providers of reliable extrusion equipment world-wide. We can guarantee customers superior quality machines up to design requirements and perfect working state. Our technicians can also provide all kinds of relevant technology to make the food production

clean, healthy and safe.

Sunpring Company has its own manufacturing plants workshops in China, business scope covering mainly machinery and equipment for corn meal milling system, corn flakes & breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system, soy nuggets system; as well as pet food/fish food system.

Sunpring Company engages in the technical research of extrusion foodstuff, in order to let our clients have superior foodstuffs to sell in the market. We can improve client's equipment and provide related training on new advanced technique. We can also make special designs for special products and materials according to clients' special requirements.

7. Contact us

Contact: Ms Alice

Email: alice@sunpring.cn

Mobile: 0086 18265413980

Web: www.amcextruder.com

Jinan Sunpring Machinery & Equipment Co.,Ltd

| Price Terms: | FOB Qingdao |

|---|---|

| Payment Terms: | TT/ LC at sight |

| Packing: | Wooden case packing |

| Lead Time: | 40 days after receipt the deposit |

Member Information

| Jinan Sunpring Machinery & Equipment Co., Ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18663764200 |

| Contact: | Cathy Hao (Manager) |

| Last Online: | 28 Mar, 2024 |

Related Products of this Company

-

Sinking Fish Feed Machinery

US $12000

-

Small Capacity Fish Feed Machinery

US $8500

-

1ton fish feed pellets Machine

US $13000

-

Floating fish feed mill

US $10000

-

Floating Fish Feed Making Machine

US $9000

-

500kg/h Fish Food Extruder

US $10000

-

Pellet Fish Feed Processing Line

US $10000

-

Fish Feed Making Machine

US $9500

-

Fish Food Pellets Production Machine

US $9500

-

5ton/h Fish Feed Plant Manufacturing

US $15000