Product Description

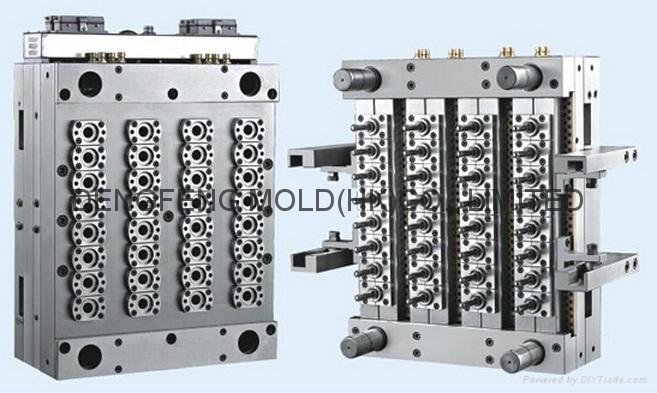

Plastic Valve Injection Mould/Mold:

1. Steel of core & cavity: 718H

2. Mould base: 45# (Customized)

3. Cavity: 1x2

3. Mould gate way: Hot runner

4. Cooling system: Enough cooling

5. Surface: High polishing

6. Tolerance: 0.02mm, 2D/3D control

7. Mould life: 500k- 1000k shots

8. Finish time for first sample: 30 days

Key Specifications/Special Features:

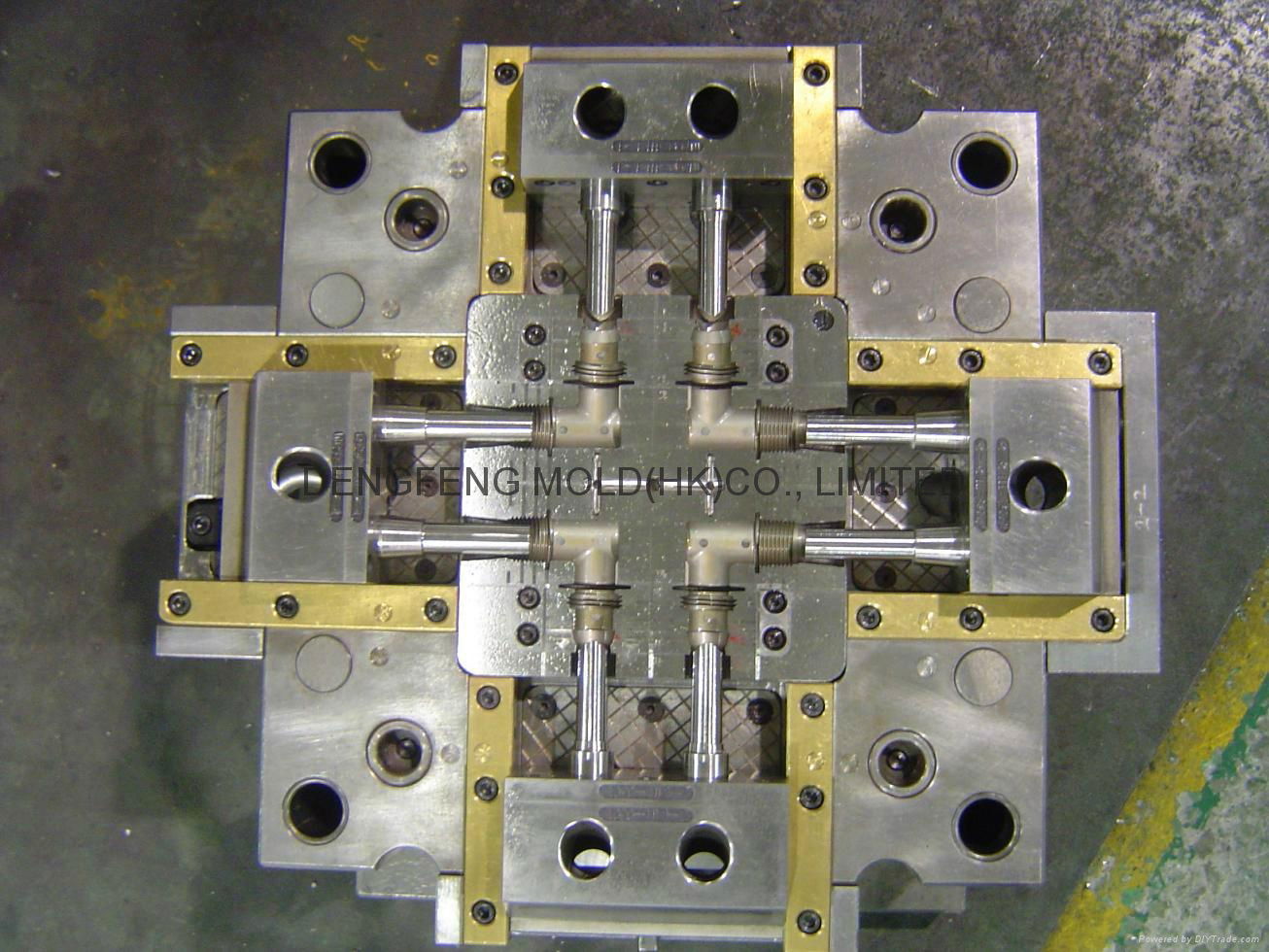

In order to make sure doff automatic and without any eject mark, must be arrange high Polish for this Plastic Valve Injection Mould/Mold. This rack choose PP material, then advice choose hard enough steel

1. Customized designs, sizes and frames are accepted

2. Mould steel: 718H forging for cor and cav, 45# for mold base (customized).

3. Mould treatment: Final treatment for cor and cav plates by vacuum queching to 30 to 36deg; (whole plates 0.3mm hardness)

4. Mould cavity: 1*2

5. Molud software: Choose UG for 3D design, AutoCAD for 2D draw, mold flow for runner analyze

6. Mould size: 280 x 220mm (depends on client's machine upon changing mold size)

7. Mould fix machine: 180T on injection molding machine

8. Plastic material: ABS (on normal choose ABS)

9. Moulding cycle time: 22 seconds/shot (without cool water when test this mold)

10. Moulding doff way: Automatic by ejectors and air spring (Hasco standard)

11. Moulding lifespan (minimum): 500, 000 shots

12. Moulding base: Copy standard mold base

13. Moulding gate way: Hot runner (customized)

14. Moulding packing: Standard wooden case

15. Minimum mold order should be one set

16. Mould shipment will be arranged within seven days after confirm samples and received balance

17. After product, if needs long time stay, should put oil (butter mix benzene) on the cor and cav, slider's surface prevents rust, with free spare parts during mold minimum life and technical Aegis.

Features:

1) We can provide for various mould moldparts according to your requirements

2) We own CNC processing centers, CNC spark working machinery and various advanced mold tooling equipment. We also have established a CAD / CAM / CAE mold design and development center.

3) Our quality, price, after sale services are really competitive

4) Our range covers from eletrical accessory, auto parts, household appliance, computer accessory, medical appliance, car accessory, digital&security parts ect.

| Material of Core & Cavity |

Cav. |

Mould Base |

Mould life(shots) |

Surface/Texture |

P20 718H NAK80 2316

SAARSRAHL AG 1.2311 |

1*2 |

LKM LKM (HASCO 50#) DME |

300000 500, 000 1000, 1000 |

EDM MOLDTECH High Polish |

| |

|

|

|

|

| Machine |

Lead Time |

Special |

Advantage |

|

| Advance CNC, EDM, W-cut |

50 Days |

Glossy Surface |

High Polish |

|

| |

|

|

|

|

| Products Details: |

|

|

|

|

| Dimension (mm) |

Material |

Dimension control |

Tolerance |

|

| |

|

2D/3D Device |

0.02mm |

|