| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In India |

| Category: | Industrial Supplies / Industrial Supplies Stocks |

| Label: | INCOLOY SHEET |

| Price: |

-

|

| Min. Order: | 10 pc |

Product Description

INCOLOY® 800H / 800HT®

ASTM B 409, B 408, B 407, B 564

UNS Number N08810/N08811

Other common names: Alloy 800, Alloy 800H/HT

Incoloy 800, 800H, and 800HT are nickel-iron-chromium alloys with good strength and excellent resistance to oxidation and carburization in high-temperature exposure. These nickel steel alloys are identical except for the higher level of carbon in alloy 800H, and the addition of up to 1.20 percent aluminum and titanium in alloy 800HT. Incoloy 800 was the first of these alloys and it was slightly modified into Incoloy 800H. This modification was to control carbon (.05-.10%) and grain size to optimize stress rupture properties. Incoloy 800HT has further modifications to the combined titanium and aluminum levels (.85-1.20%) to ensure optimum high temperature properties

In what forms is Incoloy® 800H/HT available at K PIPES & TUBES?

- Sheet

- Plate

- Bar

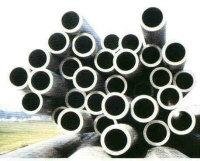

- Pipe & Tube (welded & seamless)

- Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints, long welding necks, socket welds, elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples)

- Wire

Alloy 800 (UNS N08800) Chemical Composition, %

| Ni | Fe | Cr | Cu | Ti | Al | C | Mn | S | Si |

| 30.0-35.0 | 39.5 min | 19.0-23.0 | .75 max | .15-.60 | .15-.60 | .1 max | 1.5 max | .015 max | 1.0 max |

Alloy 800H (UNS N08810) Chemical Composition, %

| Ni | Fe | Cr | Cu | Ti | Al | C | Mn | S | Si |

| 30.0-35.0 | 39.5 min | 19.0-23.0 | .75 max | .15-.60 | .15-.60 | .05-.10 max | 1.5 max | .015 max | 1.0 max |

Alloy 800HT (UNS N08811) Chemical Composition, %

| Ni | Fe | Cr | Cu | Ti | Al | C | Mn | S | Si |

| 30.0-35.0 | 39.5 min | 19.0-23.0 | .75 max | .25-.60 | .85-1.20 | .06-.10 max | 1.5 max | .015 max | 1.0 max |

In what applications is Incoloy 800H/HT used?

- Ethylene furnace quench boilers

- Hydrocarbon cracking

- Valves, fittings and other components exposed to corrosive attack from 1100-1800° F

- Industrial furnaces

- Heat-treating equipment

- Chemical and petrochemical processing

- Super-heater and re-heaters in power plants

- Pressure vessels

- Heat exchangers

ASTM Specifications

| Alloy | Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Forging | Fitting |

| Alloy 800 (UNS N08800) | B407 | B154 | B163 | B515 | B409 | B408 | B564 | B366 |

| Alloy 800H (UNS N08810) | B407 | B154 | B163 | B515 | B409 | B408 | B564 | B366 |

| Alloy 800HT (UNS N08811) | B407 | B154 | B163 | B515 | B409 | B408 | B564 | B366 |

Mechanical Properties

Typical room temperature Tensile Properties of Annealed Material

| Product | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) |

| Rod & Bar | 75-100 | 30-60 | 60-30 |

Member Information

| K PIPES & TUBES | |

|---|---|

| Country/Region: | India |

| Business Nature: | Manufacturer |

| Phone: | 67436561 |

| Contact: | PANKAJ GANDHI (EXPORT MANAGER) |

| Last Online: | 05 Nov, 2014 |