| Model: | HZG-30,40,50 |

|---|---|

| Brand: | Henkel |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | pipe making machine , ss tube mill , pipemachine exporter |

| Price: |

-

|

| Min. Order: | 1 pc |

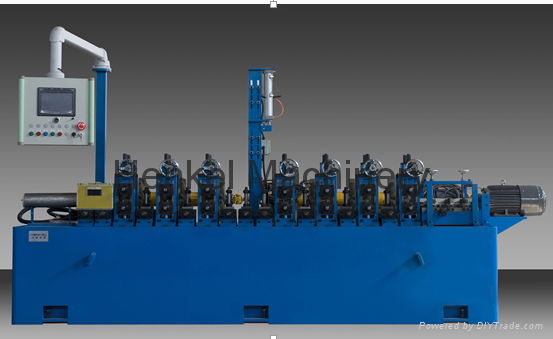

Product Description

HZG Series Full-auto Welded Pipe Making Machine mainly includes Tricathode Welding System,Inner Welded Bead Leveling Equipment and On-line Annealing Equipment.With high-performance precise PLC,Human-machine Interface and one -key start operation,it is easy ,safe and reliable for operation.The welded pipe products meet the requirements of ASTM A249,A269,A270,A312 of US standards,GB151,GB12771,HG-20537.1-4 international standards, DIN and ISO.

Process of the full-auto industrial welded pipe making machine line:

1.2.1 Uncoiler:With the resistance of the uncoiler and driven by the moulding machine,the steel strips keep going forward with constant speed under stable tensility.

1.2.2 Strips cutting and splicing machine:In order to keep the spliced strips straight and flat,cut the end first and then weld by TIGwelding machine.

1.2.3 Store holder:In order to keep the continuity of the production line and supply sufficient time for strip splicing,put the rear 30 meters of the steel strip into the loop.

1.2.4 Leveling machine:Lead the steel strip into the forming machine stably.

1.2.5 Forming machine:Roll the steel plates into the pipes .

1.2.6 Welding system:Tig welding or plasma welding by single or multiple welding torches.

1.2.7 Water-cooling :Need rapid water-cooling.

1.2.8Weld bead deviation rectifying :Rectify the deviation of the welding seam.

1.2.9 Weld bead leveling equipment :Roll the inner weld bead and eliminate the unevenness to keep the inner wall of the steel pipe smooth.

1.2.10 Polishing machine :Grind the outer weld bead to make the surface smooth.

1.2.11 First Sizing:Size the welded pipe after surface treatment and maintain the tension of the system.

1.2.12 Washing machine:Wash away the stain on the surface of the steel pipe.

1.2.13 Annealing equipment:Eliminate the stress,reduce the hardness and improve the mechanical strength through solution treatment.

1.2.14 Water Cooling system:Lower the temperature of the steel pipe to normal temperature rapidly.

1.2.15 Final sizing:Size the pipe at determined diameter accurately.

1.2.16 Aligning Machine:Align the steel pipe to keep it straight.

1.2.Inline digital flying saw:cut to specified-length automatically.

Member Information

| Guangdong Henkel Machinery Co.,Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13250366801 |

| Contact: | Shelly Lin (export trader ) |

| Last Online: | 28 Feb, 2015 |