| Model: | RCS系统塔吊配电柜 |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Other Electrical & Electronic |

| Label: | - |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Double motor RCS is applied widely in large and medium-sized tower crane hoist a hoisting mechanism. In use process has achieved wide speed range, high reliability, low failure rate of a significant effect.

In recent years, the tower crane as an important model in construction machinery, whether in the varieties, specifications, models, performance and quality, have very big development. In the early 1980 s, by the French botin company introduces the production technology of tower crane, greatly improving the tower crane production technology level of our country. Double motor RCS lifting mechanism is one of the widely used at present, China's large and medium-sized tower crane hoisting mechanism, summed up the use of 20 years experience, combined with the development level of industry in China, on the basis of the localization, the technical renovation, the agency will improve the reliability of the agency, reduce the failure rate, to expand the application scope of the agency.

The working principle of the

RCS lifting mechanism is made up of two identical wound rotor motor with brake, a known as the 12 motor at low speed, a known as the high speed motor, through the ratio of 1:2 gears connected with reducer. Work, by a drive motor rotor string resistance, increase the rotor current, increase the motor torque, to achieve the purpose of accelerating; Another being dragged motor becomes an alternator, electricity flows through the rotor after rectifying, add on the stator, it forms an electric reduction retarder, change the braking torque can speed. The RCS lifting mechanism is the feature of motor in different circuit has a variety of functions: (1) motor drive function; (2) generator function; (3) electric reduction retarder function; (4) mechanical brake function.

Two identical with mechanical brake of wound rotor motor and restraining each other to form a closed loop control. Potential energy load falls, completely avoid the problem of stall. Two motor winding are exactly the same, so they can share a resistor. Speed control is divided into five, the drag load movement speed, no matter how the hoisting speed (or down), are able to run at top speed, hoisting load can accurate safety in place, the work is smooth, maximum speed range for 1:40, thus improve the production efficiency.

Two technical transformation

The performance is good, but because of improper operation, sometimes the failure rate is on the high side. We will from selection, electric control system, motor speed control features, and manners of accelerating technical renovation, and increase the reliability of the agency application.

Electric control system of 1.

RCS lifting mechanism of the two Shared a motor resistance box, with five contactor to control relay, low reliability, high failure rate. The original electric power distribution box with a total of 12 intermediate relay, five time delay relay, 13 contactor. Due to selection and poor working conditions, two accelerated time delay relay and deceleration delay relay often make the system does not work.

Tower crane driver of wrong operation cause high failure rate. To minimize the wrong operation, according to analyzing the RCS of the working process of the lifting mechanism, we use programmable controller instead of relay, the RCS lifting mechanism for the new panel design. We choose the small integrated programmable controller memory, processing speed, is rich in a variety of functional components. Make full use of the condition control and command control, timing, status, function, instead of the original control of the relay, decelerator, meet the requirements of each movement transition, realize the complex control functions. To overcome the impact of the speed adjustment process, improve the reliability of system, reduce the failure rate of the machine.

2. The motor

RCS lifting mechanism using two of the same motor, the current domestic generally choose 51.5 KW motor.

The motor is the introduction of French technology of domestic product, the peak torque ratio up to 3.2 times more. = 3.2 Mm maximum torque Mz = 1091 nm.

RCS starting speed regulation hoist, the drive motor rotor concatenated for three period of resistance, formed three artificial mechanical characteristic curve. To the switching torque M2 = 1.2 MZ for switch point, draw according to calculate the mechanical properties, the M2 for the motor torque, the M2 motor rated torque, ne motor rated speed, Mm maximum torque motor.

3. The speed regulation characteristic

(1) the original motor mechanical properties analysis

Can be seen from the figure 1 is the dynamic process of drive motor and the original resistance into three segments, and unreasonable ratio of speed control in the process of impact.

By the combination of 3 (1) rotor resistance resistance to switch to the combination of 2 paragraphs, the maximum torque M1 = 2.05 Mz, torque range (M1, M2) is 0.85 times the rated torque of Mz.

(2) by the combination of 4 period of resistance to switch to the concatenated 1 period of resistance, the maximum torque M1 = 2.76 Mz, torque changes (M1, M2) range is 1.56 times the rated torque of Mz.

(3) when the rotor to remove the last 1 period of resistance, the maximum torque M1 to achieve maximum torque of the motor (3.2 times the rated torque of MZ).

(2) mechanical characteristics after improving design analysis

According to the RCS of hoist, motor rotor string resistance by switching by three to four paragraphs, and the ratio adjustment, will be very different. According to calculate the slip and the relative ratio of 1:2.

Site navigation

Site navigation

cademic journals

Political and legal education periodical literature periodical medical journal economic journal agricultural sci-tech periodical electronic information journals

Electronic information

Radio and television science and technology of intelligent photoelectric technology computer information management of computer network communication information security microelectronics computer application software development of biomedical engineering application of electronic technology

Political and legal

Social security of city management in international politics, military ideological and political administration law international law civil marriage and family environmental law in the criminal litigation of intellectual property rights in civil and criminal law criminal law legal history administrative law constitution

Agricultural papers

Agricultural economy science and animal science crop production of agricultural engineering science and agricultural environment science

Institute of paper

Architectural design of urban planning of mining mechanical and electrical integration of transport packaging chemical metallurgical machinery industrial design thesis power hydraulic automation vehicle

Medical paper

Psychiatric rehabilitation medicine medical check study of nutrition medicine clinical preventive medicine foundation

Economic management

Postal property of franchising catering human cultural industry project management of domestic insurance business property economics international tourism e-commerce taxation bank securities marketing financial audit accounting statistics

Literature and art

Art paper, broadcasting and hosting news animation art design director paper drama music philosophy history sociology logic aesthetic ethics psychology paper literature outside literature, advertising, public relations

Education thesis

Education technology, special education, film and television education art education sports education the humanities education adult education vocational education pedagogy preschool education education elementary education of higher education of primary school education mathematical astronomy physics and chemistry

news

News center industry information project access web announcement

Ring network, China - journal of academic journal - political law - education - literary journals - medical journal - economic journal - - electronic information - agricultural journals of science and technology journals - news center - information - the project vision - web announcement

Chinese song network

Map of library academic papers academic journal | | journal papers published hotline: 400-0158-919

Journal articles

Academic papers,

, political law

• education thesis

Literature and art,

• medical paper

• economic management

, institute of paper

Electronic information,

Agricultural papers,

Theory of education, publishing an effective way to develop rural primary school students English study interest

University journal core journals "poor student" in the junior middle school mathematics teaching

• high school political review method to guide exploration of large class paper

Post can contribute the publication of information technology, the application of new curriculum reform in junior high school English teaching

Contribute, primary school education core journals interactive teaching role in mathematics teaching

Your current location: home > > paper dissertation > mechanical institute of technology

Tower crane RCS of technical innovation and application

Source: China ring net location: mechanical paper time: 2011-07-26 07:54 145

Abstract: the dual motor RCS is applied widely in large and medium-sized tower crane hoist a hoisting mechanism. In this paper, the composition, electric motor type selection, control mode, software programming and so on technical renovation, in use process has achieved wide speed range, high reliability, low failure rate of a significant effect.

Key words: tower crane, RCS lifting mechanism; Technical innovation; application

In recent years, the tower crane as an important model in construction machinery, whether in the varieties, specifications, models, performance and quality, have very big development. In the early 1980 s, by the French botin company introduces the production technology of tower crane, greatly improving the tower crane production technology level of our country. Double motor RCS lifting mechanism is one of the widely used at present, China's large and medium-sized tower crane hoisting mechanism, summed up the use of 20 years experience, combined with the development level of industry in China, on the basis of the localization, the technical renovation, the agency will improve the reliability of the agency, reduce the failure rate, to expand the application scope of the agency.

The working principle of the

RCS lifting mechanism is made up of two identical wound rotor motor with brake, a known as the 12 motor at low speed, a known as the high speed motor, through the ratio of 1:2 gears connected with reducer. Work, by a drive motor rotor string resistance, increase the rotor current, increase the motor torque, to achieve the purpose of accelerating; Another being dragged motor becomes an alternator, electricity flows through the rotor after rectifying, add on the stator, it forms an electric reduction retarder, change the braking torque can speed. The RCS lifting mechanism is the feature of motor in different circuit has a variety of functions: (1) motor drive function; (2) generator function; (3) electric reduction retarder function; (4) mechanical brake function.

Two identical with mechanical brake of wound rotor motor and restraining each other to form a closed loop control. Potential energy load falls, completely avoid the problem of stall. Two motor winding are exactly the same, so they can share a resistor. Speed control is divided into five, the drag load movement speed, no matter how the hoisting speed (or down), are able to run at top speed, hoisting load can accurate safety in place, the work is smooth, maximum speed range for 1:40, thus improve the production efficiency.

Two technical transformation

The performance is good, but because of improper operation, sometimes the failure rate is on the high side. We will from selection, electric control system, motor speed control features, and manners of accelerating technical renovation, and increase the reliability of the agency application.

Electric control system of 1.

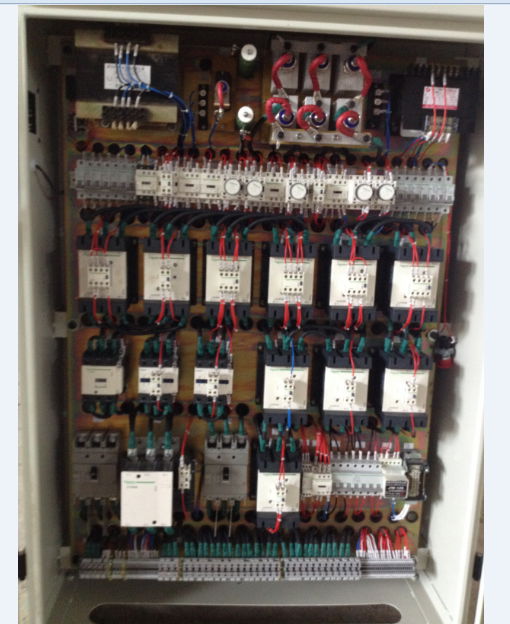

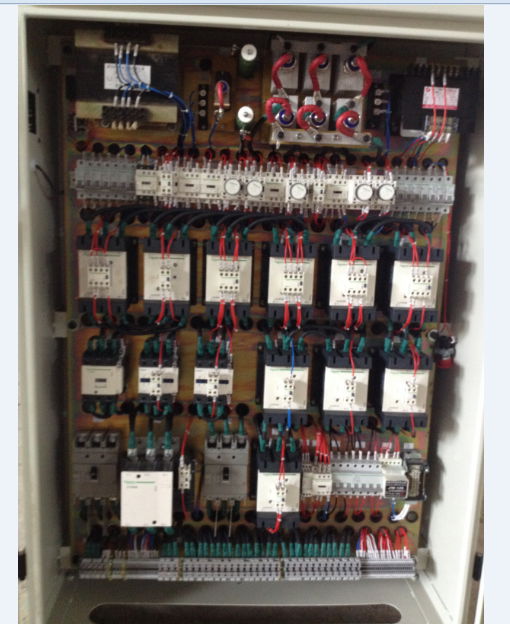

RCS lifting mechanism of the two Shared a motor resistance box, with five contactor to control relay, low reliability, high failure rate. The original electric power distribution box with a total of 12 intermediate relay, five time delay relay, 13 contactor. Due to selection and poor working conditions, two accelerated time delay relay and deceleration delay relay often make the system does not work.

Tower crane driver of wrong operation cause high failure rate. To minimize the wrong operation, according to analyzing the RCS of the working process of the lifting mechanism, we use programmable controller instead of relay, the RCS lifting mechanism for the new panel design. We choose the small integrated programmable controller memory, processing speed, is rich in a variety of functional components. Make full use of the condition control and command control, timing, status, function, instead of the original control of the relay, decelerator, meet the requirements of each movement transition, realize the complex control functions. To overcome the impact of the speed adjustment process, improve the reliability of system, reduce the failure rate of the machine.

2. The motor

RCS lifting mechanism using two of the same motor, the current domestic generally choose 51.5 KW motor, basic parameters are shown in table 1.

Table 1 ytsr180m2-4 motor parameter table

The motor is the introduction of French technology of domestic product, the peak torque ratio up to 3.2 times more. = 3.2 Mm maximum torque Mz = 1091 nm.

RCS starting speed regulation hoist, the drive motor rotor concatenated for three period of resistance, formed three artificial mechanical characteristic curve. In the switching torque M2 = 1.2 MZ for switch point, draw according to calculate the mechanical properties, as shown in figure 1. Figure s for an induction motor, the M2 for the motor torque, the M2 motor rated torque, ne motor rated speed, Mm maximum torque motor.

Figure 1 original design mechanical properties

Can be seen from the diagram, the RCS lifting mechanism of motor rotor resistance in the removal of the paragraph 1 and paragraph 2, the maximum torque value were 2.05 and 2.76 times the rated torque, already big. In the removal of the third paragraph, the switching torque value reached the maximum torque of the motor, or 3.2 times the rated torque, so the impact of the large torque motor, contactor, lifting mechanism on the high side one of the important reasons for the failure rate. Look from years of usage, large motor selection, dynamic impact is too large, high failure rate, need to undertake technical reformation. We think to choose 41 kw motor can completely meet the needs of the construction site actual use, basic parameters are shown in table 2.

Table 2 ytsr180m1-4 motor basic parameter

Maximum torque of the motor will reduce 221 nm, greatly reducing the impact to the electrical and mechanical. Based on this, if again from governing characteristic on technical renovation, impact torque can reduce more, is bound to reduce the electrical and mechanical equipment failure rate.

3. The speed regulation characteristic

(1) the original motor mechanical properties analysis

Can be seen from the figure 1 is the dynamic process of drive motor and the original resistance into three segments, and unreasonable ratio of speed control in the process of impact.

By the combination of 3 (1) rotor resistance resistance to switch to the combination of 2 paragraphs, the maximum torque M1 = 2.05 Mz, torque range (M1, M2) is 0.85 times the rated torque of Mz.

(2) by the combination of 4 period of resistance to switch to the concatenated 1 period of resistance, the maximum torque M1 = 2.76 Mz, torque changes (M1, M2) range is 1.56 times the rated torque of Mz.

(3) when the rotor to remove the last 1 period of resistance, the maximum torque M1 to achieve maximum torque of the motor (3.2 times the rated torque of MZ).

(2) mechanical characteristics after improving design analysis

According to the RCS of hoist, motor rotor string resistance by switching by three to four paragraphs, and the ratio adjustment, will be very different. According to calculating the relative slip ratio of 1:2, our pressing M2 = 1.2 MZ draw its artificial mechanical characteristic curve, as shown in figure 2.

Figure 2 m2 = 1.2 mechanical characteristics of MZ

Can be seen from the figure 2 when M2 = 1.2 MZ, rotor respectively in sub 4 period of resistance, torque rate (M1, M2)

Only: 1.12 MZ, 1.20 M, 1.23 MZ, 1.03 MZ, and switch resistance peak torque (M1) is only 2.43 MZ.

Through the above analysis, we can clearly see that: the rotor by a string of 3 to switch to string of four paragraphs, the smaller the switching torque M2 is the smaller torque dynamic range, the maximum torque will be smaller, have played an important role in pieces. When switching torque M2 = 1.2 MZ, switch the maximum torque M1 and only 2.43 MZ, it is completely can satisfy the working requirements of a smooth transition when starting and speed regulation. Through the motor selection and redesign the way of speed adjustment, the system's maximum work torque by 1091 nm, reduced to 661 nm, the impact will be significantly reduced.

4. Speed way

Composed of relay - contactor electric control system, lifting 1, 2, 3, block, PV motor acceleration, GV motor slowdown. Block, 4 GV motor is removed, PV motor rotor delay sealing off 2 period of resistance, in turn and then to PV the rated speed of the motor running. To 5 block, PV motor is removed, GV motor under the condition of the rotor 2 period of resistance connected to the circuit. Then GV motor rotor with the same way delay sealing off 2 period of resistance, in turn to GV the rated speed of the motor running. 4, 5 block of switching between two motor caused unnecessary impact.

Member Information

| Sichuan Weiweixinyi Trading Co., Ltd. | |

|---|---|

| Country/Region: | Si chuan - China |

| Business Nature: | Trading Company |

| Phone: | 15908104914 |

| Contact: | Li changping (Company manager) |

| Last Online: | 27 Feb, 2017 |