| Model: | Blend- Calcium |

|---|---|

| Brand: | SCIENOC |

| Origin: | Made In China |

| Category: | Chemicals / High Polymers |

| Label: | Blend- Calcium , Silicate , silica gel |

| Price: |

US $1

/ KG

|

| Min. Order: | 100 KG |

Product Description

Arkema Vultac 5 equivalent; sulfur content is 20.0-22.0 %.nitrosamine free curing & vulcanizing agents for natural and synthetic rubbers; It will produces a high percentage of mono-sulfidic crosslinks that results in vulcanizates with superior aging characteristics; It can be used as either complete or partial replacements for sulfur and thiuram and DTDM sulfur donors in EV and semi-EV type cure systems and so on.

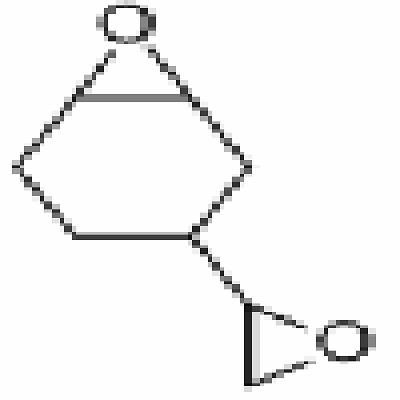

Composition: tert-amylphenol disulfide polymer(75% )+silica gel(25%)

Synonym:

Mixture of tert-amylphenol disulfide polymer and silica gel

Amylphenol disulfide polymer;

Arkema Vultac 5 equivalent;

Poly-amylphenol disulfide polymer

Blend- Calcium Silicate, Amyl Disulfide Polymer

Curing Resin

Specification:

| Item | Standard | Test Way |

| Appearance | Beige free flowing powder | Visual |

| Sulfur content, % | 20.0-22.0 | Combustion |

| % Passing 50 Mesh | ≥98 | / |

| % Passing 20 Mesh | ≥99 | / |

| Water content,% | ≤2 | / |

Application:

● Amylphenol disulfide oligomer VA-5 is a Sulfur donor for natural and synthetic rubbers.

● Amylphenol disulfide oligomer VA-5 produces a high percentage of mono-sulfidic crosslinks that results in vulcanizates with superior aging characteristics.

● Amylphenol disulfide oligomer VA-5 can be used as either complete or partial replacements for sulfur and thiuram and DTDM sulfur donors in EV and semi-EV type cure systems.

● In tires Amylphenol disulfide oligomer VA-5 is used in the inner-liner, chafer,bead apex, sidewalls, and tread.

● Industrial applications include noise damping blocks, motor mounts, dock fenders, elastic threads, automobile engine hoses, gaskets, belts, and other industrial rubber products that require good heat resistance.

● Amylphenol disulfide oligomer VA-5 also aid in rubber processing.

● Amylphenol disulfide oligomer VA-5 polychloroprene vulcanizates have improved flex life.

● Amylphenol disulfide oligomer VA-5 is also an excellent bleaching agent,antioxidant,catalysts in the disproportionation of rosin or rosin esters.

Characteristics:

● Polymers: Natural rubber and synthetic elastomers. Especially good in curing rubber that contains chlorine such as chlorobutyl and polychloroprene.

● Synergism: Can be used with most typical rubber accelerators and sulfur. When used as a partial replacement for sulfur, Amylphenol disulfide polymer 5 tends to improve dispersion of other additives in the rubber.

● Crosslink Type: Amylphenol disulfide polymer 5 promotes mono-sulfidic crosslinks resulting in vulcanizates with excellent heat and aging resistance.

● Non-nitrosamine: Amylphenol disulfide polymer 5 does not produce nitrosamines like many of the other sulfur donors such as DTDM and the thiurams.

Advantages:

● Non-nitrosamine

● Lower tack to make it easier to stock and handle

● Lower volatility

● Lower volatile degradation products

● Good compatibility with many rubber polymers

● Very good antioxidant properties

● Improve heat age properties of vulcanizates because of its generation of mono- and di-sulfic crosslinks

● Increase the resinous plasticizer during processing

● Increase the green tack in NBR,BR and SBR based compounds

● Improve the dispersion of other compound ingredients into rubber

Package:

25kgs/paper drum

25kgs/kraft bag

25kgs/carton box

or as customer’s request;

Storage:

It should be stored in dry & cool environment(below 86 °F/30℃) in closed original containers.

Shelf Life:

2 years if stored as indicated above

Member Information

| QINGDAO SCIENOC CHEMICAL CO., LTD | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18207214811 |

| Contact: | kreiss white (sales manager) |

| Last Online: | 26 Mar, 2015 |