Galvanized steel pipe cold tube plating, hot dip tube

Is to make the molten metal and iron substrate reaction and produce alloy layer, so that the substrate and coating combination of both.Is hot dip galvanized steel pipes to pickling, in order to remove iron oxide on the surface of the steel tube after acid cleaning, by ammonium chloride or zinc chloride or ammonium chloride and zinc chloride mixed aqueous solution tank cleaning, and then sent to the hot dip plating tank.Hot dip galvanized with uniform coating, strong adhesion, long service life, etc.Most of the northern process using galvanized with direct volume tube zinc supplementation.

Cold galvanizing is electricity galvanized, galvanized quantity very few, only 10 to 50 g/m2, its corrosion resistance than galvanized pipe vary a lot.Normal galvanized pipe manufacturers, in order to guarantee the quality, most do not use electric galvanized (cold) plating.Only those small and old equipment of small businesses use electric galvanized, of course, their price is relatively cheaper.The future not be allowed to use cold galvanized pipe for water and gas pipe

Steel substrate with molten electrolyte solution in complex physical and chemical reaction, the formation of corrosion resistance of the structure compact zinc alloy layer.Pure zinc alloy layer and layer and steel substrate.So the corrosion resistant ability

1, grades, and chemical composition

Galvanized steel pipe with steel grades and chemical composition should meet the requirements of GB 3091 clarinet steel grades and chemical composition.

2, manufacturing methods,

Clarinet manufacturing methods (furnace or electric welding) welding choice by the manufacturer.Galvanized by hot dip galvanizing

The production process

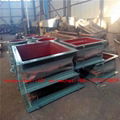

Black piece of check - hanging - skim - rinse - acid - cleaning - dipping plating aid to hot air drying, hot dip galvanized, inside and outside to cooling, passivation and rinse to unloading, inspection, repair - type logo - packing warehousing and transportation.

Galvanized volumes of belt - open book to stretch, to welding to scraping scar, passivation and rinse, zinc supplementation to finalize the design, type logo - cutting - packaging - drying - weighing.