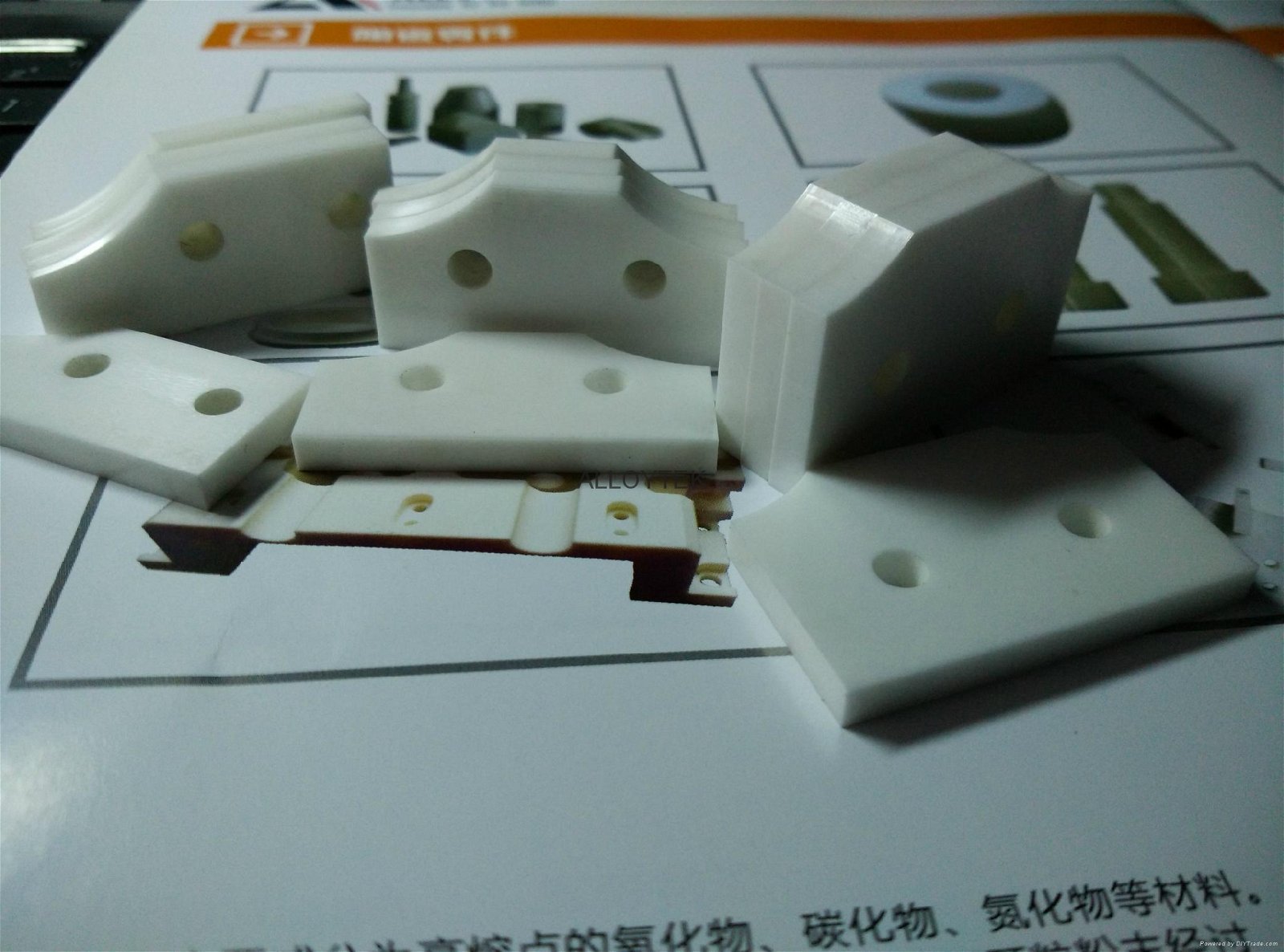

The use of the:

Alumina ceramics: (circuit board substrate, insulation parts, mechanical parts, wear plate)

1, relatively traditional materials and machinable ceramics, high strength, high hardness and good wear resistance.

2, nonmagnetic.

3, good mechanical properties at high temperature, under the condition of high temperature performance is not significantly attenuated.

4, good chemical stability, has excellent resistance to chemical corrosion.

5, has electrical insulation and low dielectric loss.

Zirconia ceramics: (bearing, blade,)

1, the alumina ceramic has high strength and high hardness, but also has a certain fracture toughness.

2, good abrasion resistance (better than metal material several times).

3, no magnetic and electrical insulation.

4, insulation.

5, acid and alkali corrosion medium.

6, self lubrication.

Ceramic processing: (structure of precision machining parts)

1 pieces of plastic, relatively high strength, high temperature resistance.

2, the most easy processing of industrial ceramics.

3, corrosion, relatively poor alumina and zirconia.