| Model: | zm-r590 |

|---|---|

| Brand: | seamarkzm |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Machinery |

| Label: | bga repair station , rework bga machine , bga welding machine |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

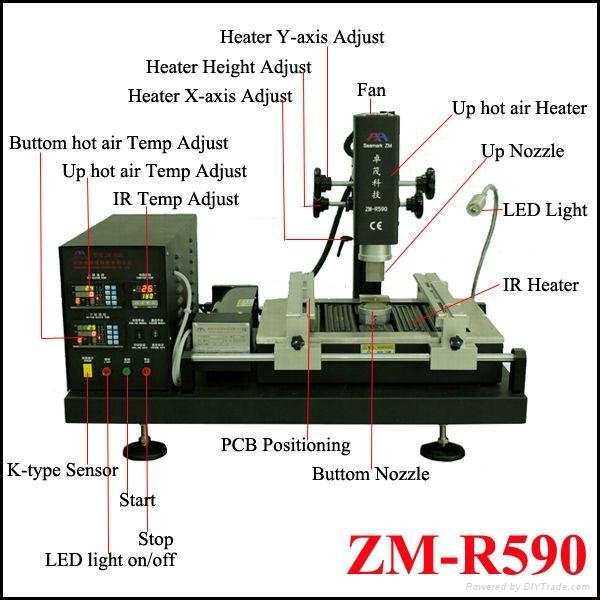

ZM-R590 digital bga rework machine

1,support PC operation

2,Top and bottom hot air heater, 3rd infrared heater

3,PLC control

4,save 10 groups of temperature parameters

5,alarming in advance

MainFeatures:

1. Adopt liner slide which makes X、Y、Z axis all can do precision adjustment and fast positioning.

2. High-precision temperature controller, built-in PC serial port, external sensor, can be controlled by computer. Temperature parameters can be setting and running on the computer.

3. There are 3 independent heating areas from top to bottom. The 1st and 2nd are hot-air heaters, the 3rdis IR preheating, temperature controlled within ±3 °, Top heater can be adjusted freely, second heater can be adjusted up and down, these heaters can set many groups temperature parameters at the same time; the third IR area can be adjusted the power consumption.

4. Offer all kinds of hot-air nozzle, it can rotate 360°,With magnet, easy to install and change, customized is available.

5. Choose imported high-precision K-type thermocouple, closed loop control and automatic temperature compensation system.

6. Use a V-groove equipped with a flexible fixture for PCB positioning to protect the PCB from deformation when heated or cooled, and it can rework any size of BGA chips.

7. Powerful cross-flow fan rapidly cool the PCB board to improve efficiency, also built-in vacuum pump and external vacuum suction pen, pick up the chips rapidly.

8. Before finishing desoldering & soldering, there is a warning, there are emergency stop and automatic power-off protection device when abnormal accident happens, with a double over-heating protection control.

9. Identified by CE.

10. Repair Mobile,Laptop,PS3,Xbox etc. and other components on the motherboard, it can meet repair of lead and lead free soldering&desordering.

|

1 |

PCB Size |

Max 420*390 mm Min 20*20 mm |

|

2 |

Temperature control |

(K Sensor) closed loop, independent heating, precision within±3° |

|

3 |

Heaters |

Hot air and infrared heater |

|

4 |

Positioning |

V-groove, PCB support can be adjusted in any direction and with external universal fixture |

|

5 |

Nozzle heater |

Top 800W, Bottom 1200W |

|

6 |

Bottom Preheater |

2700W |

|

7 |

Power supply |

AC220V±10% 50/60Hz |

|

8 |

dimension |

810*500*690 mm |

|

9 |

NetWeight |

45kg |

|

10 |

Wooden box Dimension |

L95*W67*H65cm. |

|

1 |

PCB Size |

Max 420*390 mm Min 20*20 mm |

|

2 |

Temperature control |

(K Sensor) closed loop, independent heating, precision within±3° |

|

3 |

Heaters |

Hot air and infrared heater |

|

4 |

Positioning |

V-groove, PCB support can be adjusted in any direction and with external universal fixture |

|

5 |

Nozzle heater |

Top 800W, Bottom 1200W |

|

6 |

Bottom Preheater |

2700W |

|

7 |

Power supply |

AC220V±10% 50/60Hz |

|

8 |

dimension |

810*500*690 mm |

|

9 |

NetWeight |

45kg |

|

10 |

Wooden box Dimension |

L95*W67*H65cm. |

Member Information

| Zhuomao technology Co.,Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18718489160 |

| Contact: | Lita Lian (sales) |

| Last Online: | 28 May, 2015 |

Related Products of this Company

-

Automatic bga soldering machine

US $5280

-

bga rework station

-

glue dispensing machine

US $3999

-

infrared bga welding machine

US $1700

-

hot air bga rework machine

-

mobile rework station

US $1600

-

bga reballing machine

US $1500