| Model: | Glass stage |

|---|---|

| Brand: | MEGO |

| Origin: | Made In China |

| Category: | Services / Commercial Service |

| Label: | Aluminum alloy stage , Organic glass stage , Toughened glass stag |

| Price: |

-

|

| Min. Order: | - |

Product Description

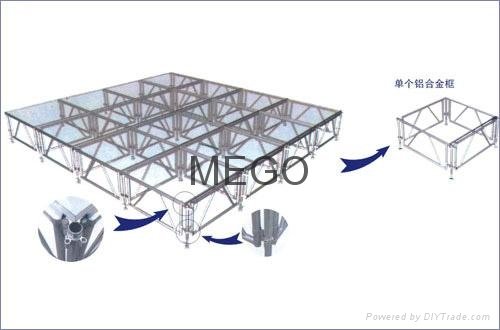

Aluminum alloy activity stage: organic glass flow stage/folding stage/hotel/mobile stage stage/assembling/disassembling stage stage/adjustable stage/transparent stage stage/crystal/glass/avenue of stars and all kinds of iron stage height 0.2 meters to 2.0 meters can be customized, size 1.22 m * 1.22 m / 1.22 m * 2.44 m / 1 m * 1 m / 1 m * 2 m, can be customized

Organic glass concept

Organic glass is a kind of popular name, from the name, you may not know it is a kind of what kind of material, also don't know if it is made up of what elements. The transparent polymer material chemical name is called polymethyl methacrylate, is composed of methyl methacrylate polymerization.

The performance of organic glass

(1) the material of organic glass chemical name is called polymethylene acid methyl ester, is made up of a methyl acrylate polymer polymer compounds. (2) application: widely used organic glass, not only in the business, light industry, construction, chemical industry, etc. And organic glass, they are widely used in advertising decoration, sand table model, such as signs, billboards, light boxes of panel and the letter in the panel. Selection depends on modelling design, what kind of modelling, with what kind of organic glass to repeatedly test, color, variety, to achieve the best results. With good design, don't rely on elaborate processing production, to become a beautiful handicraft. (3) features: smooth surface, colour is gorgeous, the proportion of small, large strength, corrosion resistance, resistance to wet, fast, good insulation performance, good sound insulation. (4) shape, can be in charge of the material, bar material, plate material 3 kinds. (5) categories: can be divided into four kinds.

Colored transparent organic glass, also known as color plate. Pervious to light is downy, made of light boxes, handicraft, it makes people feel comfortable and easy. Colored machine glass, transparent color, translucent color, not transparent colored 3 kinds. Magnetic organic glass luster as organic glass bead light bright, crisp, brittle, suitable for making the dial, box, medical apparatus and instruments and characters, animals, molding materials. Transparent organic glass, high transparency, appropriate system of lamps and lanterns. Made of it droplight, exquisite, glittering and translucent splendidly. Transparent organic glass similar ground glass, reflective soft, made of handicraft, it makes people feel comfortable and easy. Colorless transparent organic droplight, exquisite, glittering and translucent splendidly. Mobility: glass bead light are in general organic glass pearl powder or phosphor powder into. Such organic glass bright color and high surface finish, form outside the mold after hot pressing, even if the smooth polishing, still keep moulded decorative pattern, form a unique artistic effect. Use it to make character, animal model, trademarks, decorations, and publicity exhibition materials. Embossing: organic glass transparent, translucent, colorless, very brittle and break easily, suitable for production.

The birth and growth of organic glass

In 1927, German chemist roma - haas company between two pieces of glass plate heat the acrylate, acrylic ester polymerization reaction, generate the sticky rubber sandwich, can be used as a shatterproof safety glass. When they are in the same way that the polymerization of methyl methacrylate, the transparency is good, other performance is also a good organic glass plate, it is the polymethyl methacrylate. In 1931, roma - haas company factory production of poly (methyl methacrylate, has been applied first in the aircraft industry, replaced the celluloid plastic, used as aircraft canopy and the windshield. If in the production of organic glass to join all kinds of stain, it can be aggregated into colored organic glass; If add fluorescent agent (such as zinc sulfide), can be aggregated into fluorescent organic glass; If add artificial pearl powder (such as alkali lead carbonate), pearl can be obtained from organic glass.

The characteristics of organic glass

1) high transparency. Organic glass, transparent polymer materials is the most excellent, euphotic rate reached 92%, than the high light transmittance of the glass. Called artificial small sun sun lamp tube is made of quartz, this is because quartz can completely through the ultraviolet light. Ordinary glass can only through 0.6% uv, but organic glass by 73%. (2) high mechanical strength. The relative molecular mass of the organic glass is about 2 million, is a long chain of polymer compounds, and form a molecular chain is very soft, therefore, the strength of the organic glass is higher,

Tensile and impact resistant ability of 7 to 18 times higher than common glass. There is a heated and stretch the processed organic glass, one of the molecular chain arrangement is very good order, make the material toughness has improved significantly. With a nail into the organic glass, even if the nail penetrated, organic glass cracks. The organic glass was the bullet also not broken into pieces after breakdown. Therefore, organic glass can be used as bulletproof glass of the drawing processing, is also used as a canopy on military aircraft. 3. Light weight. Organic glass density of 1.18 kg/dm, the size of the same material, the weight is only half of the common glass, metal aluminum (belong to light metals) of 43%. (4) easy to processing. Organic glass not only can use lathe cutting, drilling, drilling machine and the bond into various shapes such as with acetone, chloroform, can also blow molding, plastic molding methods such as injection, extrusion processing into large canopy to aircraft, small to the false teeth and a variety of products such as plates

Tensile and impact resistant ability of 7 to 18 times higher than common glass. There is a heated and stretch the processed organic glass, one of the molecular chain arrangement is very good order, make the material toughness has improved significantly. With a nail into the organic glass, even if the nail penetrated, organic glass cracks. The organic glass was the bullet also not broken into pieces after breakdown. Therefore, organic glass can be used as bulletproof glass of the drawing processing, is also used as a canopy on military aircraft. 3. Light weight. Organic glass density of 1.18 kg/dm, the size of the same material, the weight is only half of the common glass, metal aluminum (belong to light metals) of 43%. (4) easy to processing. Organic glass not only can use lathe cutting, drilling, drilling machine and the bond into various shapes such as with acetone, chloroform, can also blow molding, plastic molding methods such as injection, extrusion processing into large canopy to aircraft, small to the false teeth and a variety of products such as plates

The purpose of the "organic glass quotation

Organic glass has more excellent properties, make its use is very extensive. Except as a canopy on the plane, windshield chord of the window by any man, also used as a jeep windshield and Windows, large-scale construction of skylight can prevent breakage), television, and radar screen, instruments and equipment of the shield, telecommunications, telescope and camera on the exterior of the instrument of optical lenses. Made of organic glass full of beautiful things in eyes of daily necessities, such as made of organic glass pearl buttons, all kinds of toys, lamps and lanterns is because of the color the adornment action of the organic glass, and looks very beautiful. Organic glass and an excellent use on medicine, that is to create artificial cornea. If the transparent cornea of the human eye is full of opaque material, the light will not be able to enter the eye. This is the whole corneal leukoderma cause of blindness, and this kind of disease can't use drugs. So the medical idea of artificial cornea instead of full of white spot. So-called artificial cornea, a transparent material was used to make a mirror column, there are only a few millimeters in diameter and drill a hole on the human eye cornea, the column on the cornea, lens light through a column into the intraocular lens, the eye can see light. As early as in 1771, there is an eye doctor made column lens, optical glass implanted in cornea, but did not succeed. Then, use crystal instead of optical glass, also took six months failed. In the second world war, when some plane crash, the plane made of organic glass canopy was bombed, pilots with organic glass fragments embedded in his eyes. After many years later, although these fragments and

Have not been removed, but also not further cause eye inflammation or other adverse reactions. The accident happened that organic glass and human tissues have good compatibility. Also inspired an eye doctor, can use organic glass manufacturing artificial cornea, the pervious to light quality good, stable chemical properties, non-toxic to human body, easily processed into the required shape, can long-term compatible with human eyes. Now, made of organic glass artificial cornea has been widely used for clinical purposes.

Why is not the same as the organic glass and common glass?

Organic glass and common glass looks like a family, in fact they are not completely the same two. "Father" is a silicate of ordinary glass, but the "parents" organic glass is acetone, methanol, sulfuric acid and hydrogen cyanide. Organic glass is called polymethyl methacrylate. The name pronounced the rather awkward, because it is a kind of synthetic polymer, so people call it in general organic glass.

Organic glass character generally more stubborn than common glass. Despite its density is smaller than common glass half, but not as easily broken as the glass. Its transparency is very good, glittering and translucent get rid of is appeared, and has the very good thermoplastic, heating it, it can be any shape glass rod, glass tube and glass plate, is due to its attractive appearance and personality, so its application is very wide.

Jet aircraft in the air speed, often encounter severe vibration and temperature mutations and air pressure and other special situation, the aircraft cockpit Windows is the acid test. Who can stand the test? Organic glass. If be fighters, in pursuit of the enemy, the organic glass was hit by a bullet, it wouldn't be the whole piece of broken, and only a small hole, so it won't happen again similar glass debris of the accident. The thickness of the common glass for more than 15 cm, it becomes a piece of green, and across the glass can't see anything. Organic glass through the 1 m thick, can still clearly see the other side of the thing. Because it is pervious to light performance is quite good, coupled with ultraviolet ray also can penetrate, so it is used to manufacture optical instruments. Organic glass and have an amazing performance, a flexible organic glass rod, as long as the amount is less than 48 degrees, the light can along it, like water through the pipe project. The light can be delayed, how interesting! Using this trick, it becomes a surgery for optical glass apparatus of treasures. Therefore, when the doctor in the operating room for surgery, I don't know just don't have to worry about. Organic glass is both light and tough, chemical and fairly stable to heat and plasticity, so its application is very extensive. If appropriate to add some dyes in organic glass raw materials, according to the needs of the people, can produce red, green and purple... Organic glass with light color.

| Payment Terms: | T/T/ MoneyGram / Paypal / Western union |

|---|---|

Member Information

| Henan high stage equipment co., LTD | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 18236191555 |

| Contact: | Zhang Jinwen (Business Manager) |

| Last Online: | 04 Jul, 2016 |