| Model: | QTY3-20 |

|---|---|

| Brand: | Wante |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | Semi automatic blcok , paver machine , solid hollow brick |

| Price: |

US $9850

/ pc

|

| Min. Order: | 1 pc |

Product Description

1. QTY3-20 hollow block making machine,interlocking brick machine price,paving brick making machine price for sale in Iraq market

Product Description

|

No. |

Model |

Qty |

Weight KGS |

KW |

|

1 |

QT3-20 block machine |

1 |

5200 |

11 |

|

2 |

JD350 mixer |

1 |

410 |

5.5 |

|

3 |

Accessory |

|

||

|

|

Hollow block Mould |

1 |

Included in the host machine |

|

|

Pallet feeder |

|

|||

|

Hydraulic station |

|

|||

|

Colorful material feeder |

1 |

|||

|

Barrow |

2 |

|||

|

conveyor |

1 |

|||

|

Tools |

1 |

|||

|

Fittings |

1 |

|||

|

4 |

FOB Qingdao |

|

5610 |

16.5 |

Specification of QTY3-20 hollow block making machine,interlocking brick machine price,paving brick making machine price for sale in Iraq market

|

Overall size |

2800(L)×1600(W)×2200(H)mm |

|

|

Shaping cycle |

20-25 seconds |

|

|

Pallet size |

680×530×30mm (bamboo) |

|

|

680×530×20mm (plastic) |

||

|

Vibration frequency |

Max.4000 R/Min |

|

|

Upper vibrator |

Hydraulic |

|

|

Nether vibrator |

11 kw |

|

|

Electricity |

380V/220V/ (adjustable) |

|

|

Total weight |

5200 KGS |

|

|

Conveyor belt |

||

|

Belt width (M) |

6 |

|

|

Belt length (M)/KW |

6/2.2 |

|

|

Belt speed (M/S) |

2 |

|

|

JD350 mixer |

||

|

Overall size |

1200(L)×1200(W)×1300(H)mm |

|

|

Shaping cycle |

5 mins |

|

|

Volume |

350L (25Kgs Cement) |

|

|

Electricity |

380V/220V/ (adjustable) |

|

|

Total weight |

330KGS |

|

Packaging & Shipping

Package of QTY3-20 hollow block making machine,interlocking brick machine price,paving brick making machine price for sale in Iraq market

1.Nude package in one container

2,Standard exported

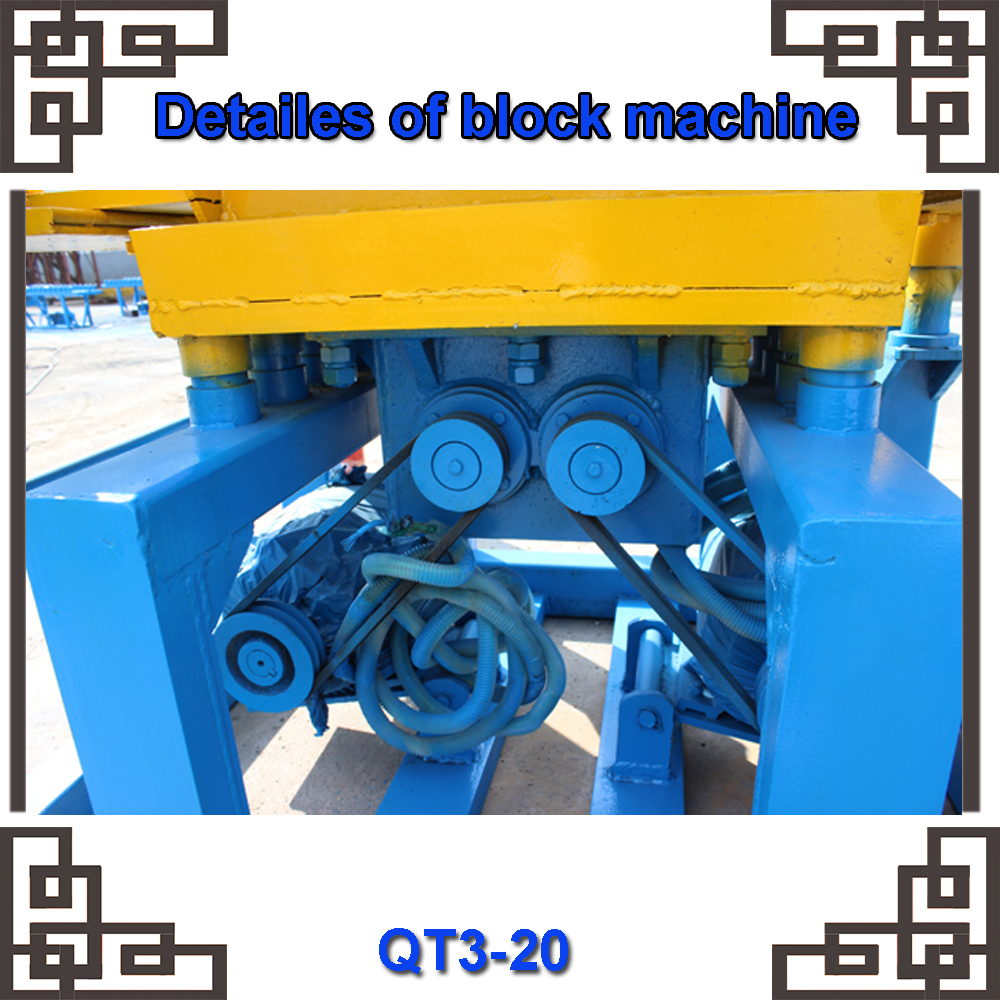

Detailes of QTY3-20 hollow block making machine,interlocking brick machine price,paving brick making machine price for sale in Iraq market

Our Services

Pre-sale

(1) Professional s estions (raw material matching, machine selection, plan

The condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line anytime,if you need, we can Make inVitation

card for you.

(5) Introduce the company file, product categories and production process.

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix,and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time,keep well communication with each other

Workers :

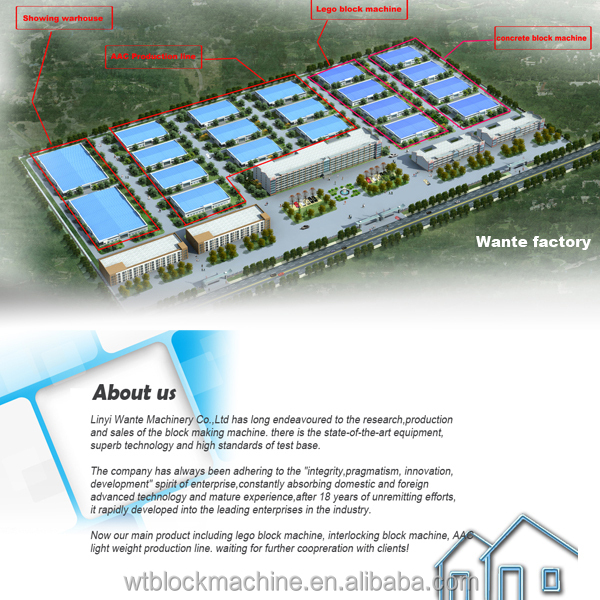

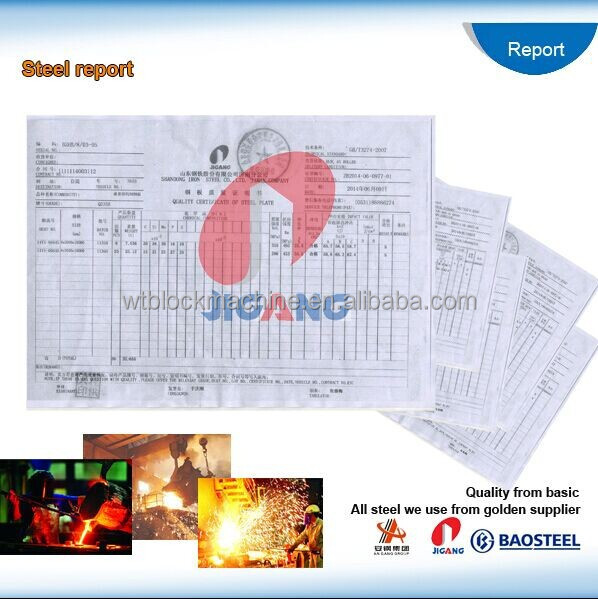

1>Our workers have en average 10 years working experience, very skillful .

2>All our raw material use the best quality in china, we cooperated with one of the biggest steel

factory,The Purchasing Department regularly do purchase from them.

3>Moulds get heat treatment and carbonization before installed on machine,more anti-wearing,

the life of mould can achieve 200000-300000 times.

4>For the motors, we use Siemens,ABB or other famous brands in china

5>Machines need to be tested by special engineer to make sure every machine operate well

before leaving our factory

Company Information

Contact

Member Information

| linyi wante machinery co.,ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Trading Company |

| Phone: | 18954991098 |

| Contact: | Mandy (sales) |

| Last Online: | 21 Mar, 2019 |

Related Products of this Company

-

QMY6-25 block machine

US $8700

-

QT4-26 block making machine

US $4600

-

QT40-3 block making machine

US $3000

-

JS500 concrete mixer

US $5500

-

WT1-10 automatic interlocking brick

US $6000

-

QT40-1 block making machine

US $3990

-

WT1-10A interlocking brick machine

US $5400

-

WT10-15 Automatic mobile hollow block

US $16100

-

Interlocking brick making machine

US $9500

-

QT40-2 Manual brick making machine

US $2700