| Model: | 20512-H13 |

|---|---|

| Brand: | YAOTENG |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Flat & Rolled Metallic Materials |

| Label: | h13 steel , h13 steel round bar , h13 tool steel |

| Price: |

¥2100

/ TON

|

| Min. Order: | 1 TON |

Product Description

hot work tool steel h13 material, H13 steel china supplier, H13 Steel

Company Information

The History of YAOTENG STEEL

•1995.10 Established tool steel Plus workshops,beginning make the

mould steel cutting process

•2001.7 Changed to limited liability company, have 8 set

semi-automatic Bandsaw Cutting machinery and 3 set planing machine.

•2004.6 All Bandsaw Cutting machinery update to CNC Machinery,1 set

large precision grinding machine and 2 set small grinding is was

introduced and purchase a set Gantry Milling

•2009.5 Establish cooperation with Changcheng Special Steel Co.,Ltd, FUSHUN special steel and BaoSteel. as the specified distributor for special steel.

•2010.2 Start International trade

•2012 Through Alibaba certified high quality suppliers

•2013 and 2014 finished the company new Shares system , Customers in more than 40 countries around the world

Product Description

AISI H13 steel -ASTM A681-1999

| Grade | C | Si | Mn | P | S | Cr | Mo | V |

| H13 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 0.030Max | 0.030Max | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 |

| SKD61 | 0.35~0.42 | 0.80~1.20 | 0.25~0.50 | 0.030Max | 0.020Max | 4.80~5.50 | 1.00~1.50 | 0.80~1.15 |

| 4Cr5MoSiV1 | 0.32~0.42 | 0.80~1.20 | 0.20~0.50 | 0.030Max | 0.030Max | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 |

| STD61 | 0.32~0.42 | 0.80~1.20 | ≤0.50 | 0.030Max | 0.030Max | 4.50~5.50 | 1.00~1.50 | 0.80~1.20 |

Supply of H13 steel material

|

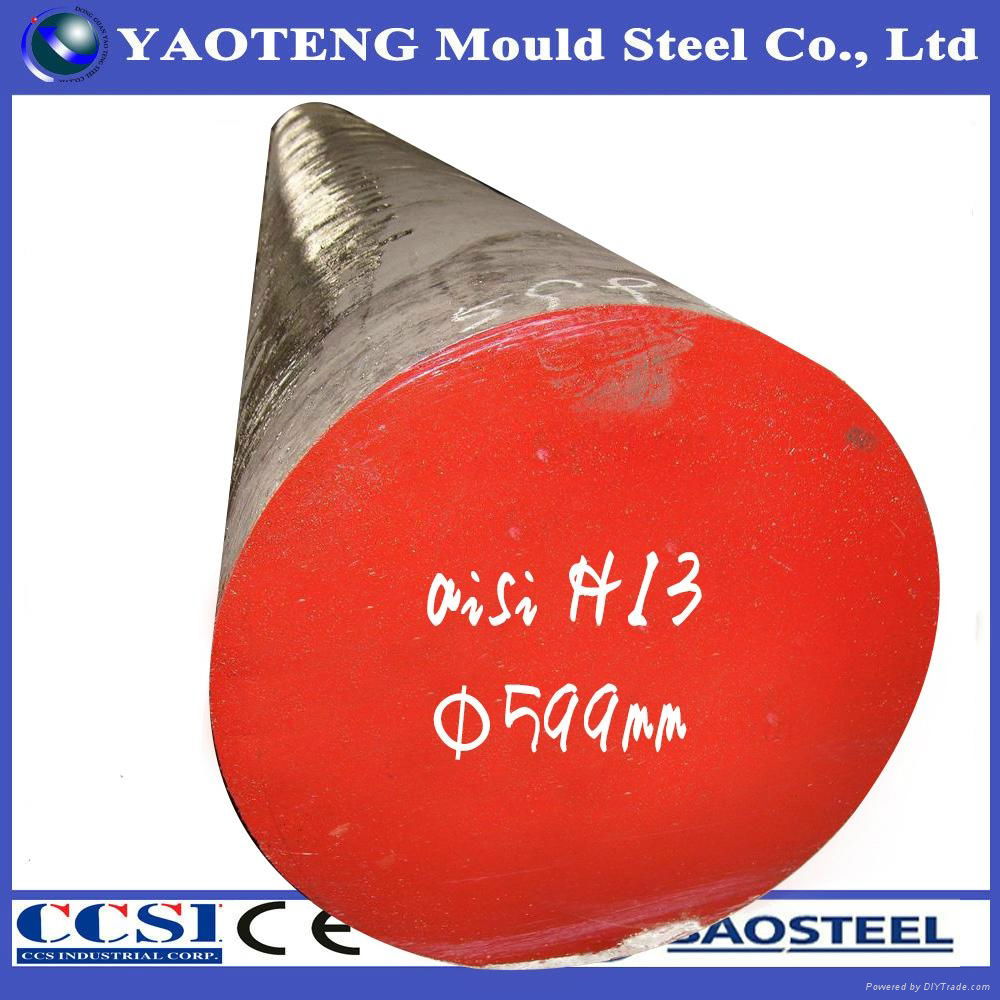

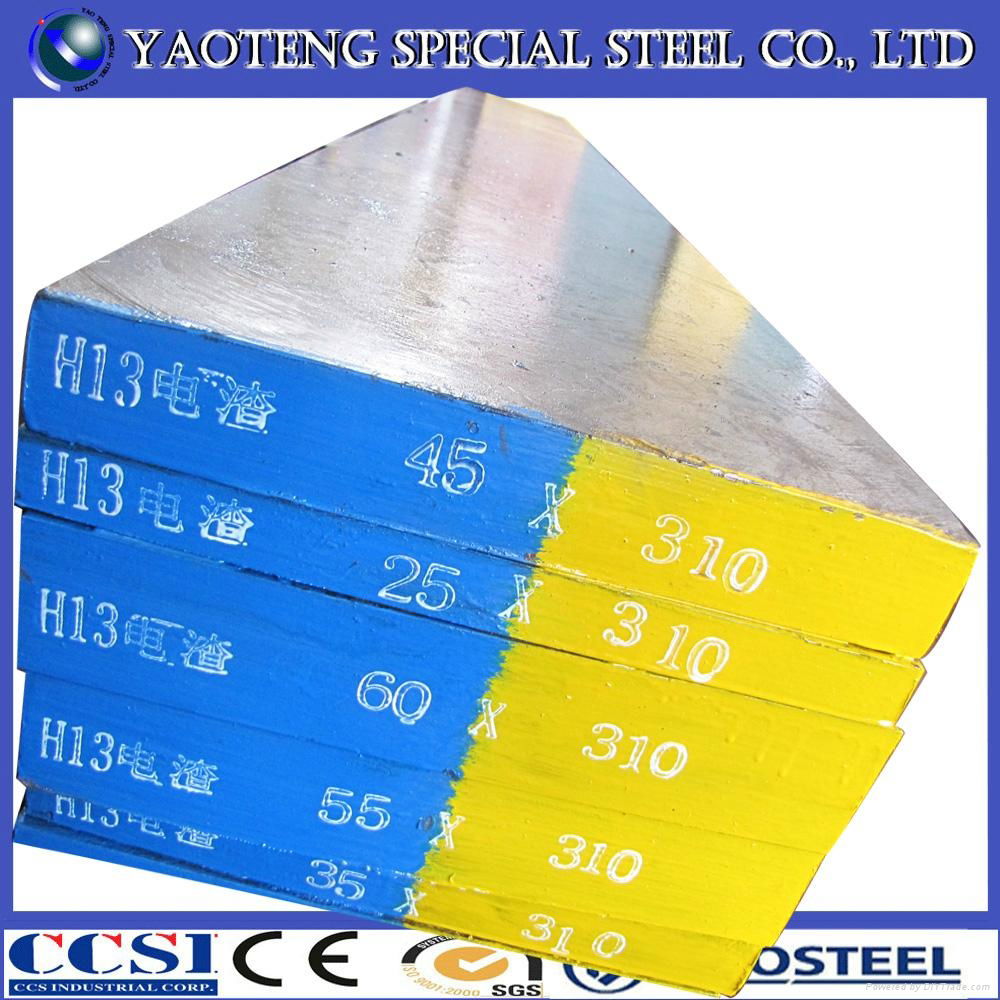

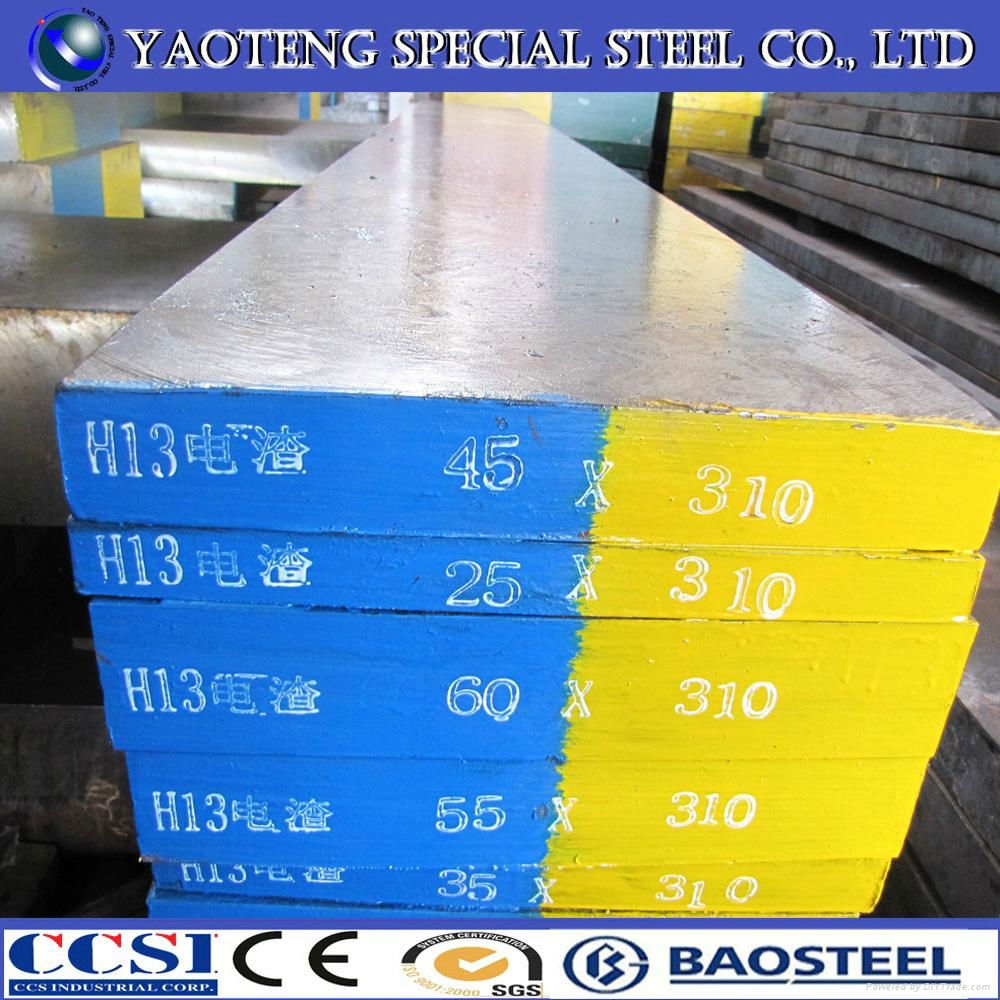

YaoTeng Steel are stockholders and suppliers of H13 tool steel round bar and flat sections which can be sawn cut to your required sizes. H13 ground steel bar can be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. H13 tool steel is also available produced as Ground Flat Stock / Gauge Plate, in standard and non standard sizes.

|

|

|

|

||

| Plate | Flat | Diameter |

Applications of H13 steel material

Typical applications include die casting dies for aluminium, magnesium and zinc, extrusion dies for aluminium and brass, liners,

mandrels, pressure pads, followers, bolsters, die cases, die holders and adaptor rings for copper and brass extrusion. H13 steel is used to produce hot stamping and press forge dies, split hot heading dies, gripper dies, hot punching, piercing and trimming tools. Other applications include plastic moulds, shear blades for hot work and hot swaging dies.

Forging of H13 steel material

Preheat slowly to 750°C then increase the temperature more rapidly to 1050-1100 °C. Do not forge below 850°C. It is essential to cool the H13 slowly after forging, either in a furnace or in vermiculite.

Annealing of H13 steel material

Soak thoroughly at 840-860°C before furnace cooling at a maximum rate of 20°C per hour down to 600°C followed by cooling in air.

Stress Relieving of H13 steel material

When tools made from H13 tool steel are heavily machined or ground , the relief of internal strains is advisable before hardening to minimise the possibility of distortion. Stress relieving should be done after rough machining. To stress relieve, heat the component carefully to 700°C, allow a good soaking period (two hours per 25mm of ruling section). Cool in the furnace or in air. The tools may then be finish machined before hardening.

Hardening of H13 steel material

Preheat to 780-820°C. Soak thoroughly, then increase rapidly to the final hardening temperature of 1000-1030°C. When the H13 has attained this temperature, soak for approximately thrity minutes. Cool in air. Large sections may be quenched in oil. To reduce scaling or decarburisation, we recommend isothermal molten salt bath treatment. Preheat in salt at 780-820°C then transfer to salt bath standing at 1000-1030°C. Soak and quench into salt standing at 500-550°C. Allow to equalise, withdraw and cool in air. Alternatively, this tool steel may be vacuum hardened or pack hardened. Tools should be tempered as soon as they become hand warm.

Tempering of H13 steel material

Heat uniformly to the required temperature allowing a soaking time of two hours per 25mm of ruling section. Withdraw from the furnace and allow to cool in air. A second tempering is strongly recommended, the H13 tool being allowed to cool to room temperature between tempers. The usual tempering range is 530-650°C depending on the hardness requirements and the operating temperature of the tool.

| Temperature [°C] | 400 | 500 | 550 | 600 | 650 |

| Hardness [HRc] | 54 | 56 | 54 | 49 | 47 |

Welding of H13 steel material

In general, we do not advise the welding of tool steel but users sometimes prefer to weld in order to avoid the cost of retooling. It should be remembered that this grade is an air hardening steel and that in welding the area of the weld attains a temperature of about 1000°C. Cracking is likely to occur during cooling unless proper precautions are taken. Popular methods of welding are atomic hydrogen and argon arc. We recommend you contact your welding consumables supplier who should provide you full assistance and information on welding tool steels.

Welding Procedure

1) It is desirable to anneal the tool prior to welding but with care welding may be done on hardened and tempered tools.

2) It is important to preheat the die to 300-500°C and to maintain this temperature during welding.

3) After the weld has been completed, maintain at 300-500°C for one hour, then cool the die slowly in a furnace or in insulating material.

4) If the tool has been annealed prior to welding, stress relieve at 700°C before re-hardening.

5) If the tool has not been annealed prior to welding, re-temper at 550-600°C for a minimum of 2 hours.

Nitriding of H13 steel material

H13 tool steel can be nitrided to give a hard surface case. The steel is then very resistant to wear and erosion. Nitriding also increases resistance to corrosion. Nitriding in ammoniac gas at a temperature of 525°C will give a surface hardness approximately 1000 to 1250HV. Before nitriding the tool should be hardened and tempered at approximately 50°C above the nitriding temperature. It is important to note that with increase in penetration of the nitriding, there is a reduction in resistance to thermal shock and an increase in embrittlement.

|

Temperature |

Time |

Approx. Depth of Case |

|

525°C |

10 hours |

0.125mm |

|

525°C |

20 hours |

0.180mm |

|

525°C |

40 hours |

0.250mm |

|

525°C |

60 hours |

0.300mm |

Final Grinding of H13 steel material

Select the correct grade of wheel in consultation with the grinding wheel manufacturer. Ensure the grinding wheel is in good condition by means of a suitable dressing tool. Wet grinding is a preferable option using a copious supply of coolant. If dry grinding is resorted to then use a very soft wheel.

Our Services

How to Contact Us?

Send your Inquiry Details in the Below, Click "Send" Now! Free samples are waiting for you.

Our Stock and Machinery

Send your Inquiry Details in the Below, Contact us Now! Free samples are waiting for you.

Member Information

| OTAI SPECIAL STEEL CO.LTD | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13414322915 |

| Contact: | JOHN LONG (salesman) |

| Last Online: | 10 Jun, 2015 |