| Model: | - |

|---|---|

| Brand: | YIMI |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Cast & Forged |

| Label: | Foam Ceramic Filter , Ceramic , Filter |

| Price: |

US $7

/ pc

|

| Min. Order: | 500 pc |

Product Description

Product Description

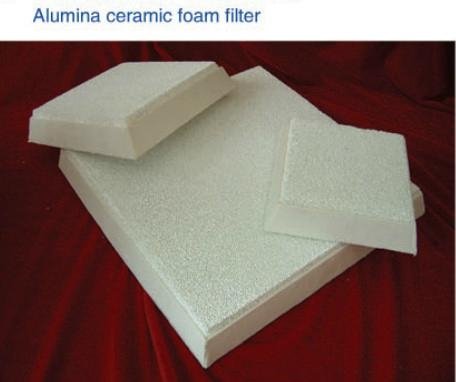

Alumina Ceramic Foam Filter mainly for filtration of aluminum and alloys in foundries and cast houses.With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow,and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Reduce scrap related to inclusions

Reduce costs related to inclusion defects

Increase productivity with higher extrusion or rolling speeds

Increase casting flexibility with easy alloy changes

No holding metal

FEATURES

Superior dimensional tolerances

Stable chemical composition

Highest filtration efficiency

Excellent strength

Resistant to corrosion attack by molten aluminium and alloys

Beveled edges and compressible gasket

SPECIFICATION

Working Temp ≤1200°C

Porosity 80-90%

Compression Strength (Room Temperature) ≥1.0Mpa

Volume Density 0.4-0.5g/cm3

Thermal Shock Resistance 800°C to room temperature 5 times

Application

Non-ferrous and alumina alloys, high temperature gas filter,chemical fillings and catalysis carrier etc.

SIZE

Range of porosities from PPI 10 up to PPI 40 (PPI = pores per inch).

Filters are available in all common sizes:7x7x2", 9x9x2",12x12x2", 15x15x2",17x17x2", 20x20x2", 23x23x2".Other sizes can be customized upon request.

PRE-HEAT

Ceramic foam filters are normally applied by placing them into a filter box.

It is important to pre-heat both filter and bowl before use. During pre-heat care must be taken to control both heat up rate and temperature distribution. This minimizes thermal shock and stresses in the filters and filter box refractory.

PRIMING

Before a filter can be used, it must be completely wetted by liquid metal. This happens during the start-up of the casting operation. The amount of metallostatic pressure (or priming head) required to wet filters depends on alloy,metal temperature, pre-heat uniformity, pre-heat temperature, incoming metal quality,pre-filter treatments and on the cell size of the filter.

Before a filter can be used, it must be completely wetted by liquid metal. This happens during the start-up of the casting operation. The amount of metallostatic pressure (or priming head) required to wet filters depends on alloy,metal temperature, pre-heat uniformity, pre-heat temperature, incoming metal quality,pre-filter treatments and on the cell size of the filter.

| Size(mm) | Size (inch) | Effective filtration area(m2) | Weight(g) | Flow Rate Range(kg/min) | Filtration capacity(ton) | Pore size |

| 178x178x50 | 7x7x2 | 0.02 | 580±40 | 25-60 | 5.0 | 10PPI

20PPI 30PPI 40PPI |

| 228x228x50 | 9x9x2 | 0.03 | 1000±60 | 40-120 | 8.0 | |

| 305x305x50 | 12x12x2 | 0.07 | 1780±120 | 90-170 | 15.0 | |

| 381x381x50 | 15x15x2 | 0.12 | 2810±180 | 150-320 | 25.0 | |

| 432x432x50 | 17x17x2 | 0.16 | 3680±210 | 210-500 | 35.0 | |

| 508x508x50 | 20x20x2 | 0.23 | 5080±240 | 280-610 | 45.0 | |

| 584x584x50 | 23x23x2 | 0.30 | 6720±270 | 370-770 | 60.0 | |

| *Tolerance for Filter Dimensions:±2mm

*10-20PPI for pouring casting *30-40PPI for semi-continuous casting |

||||||

| Payment Terms: | TT/DP/LC |

|---|---|

Member Information

| LUOYANG DEPLOITATION INDUSTRIAL I/E CO.,LTD | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 15637991156 |

| Contact: | Henry huo (manager) |

| Last Online: | 23 Jul, 2015 |