| Model: | EWD-H-J5 |

|---|---|

| Brand: | EST |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | elevator load cell , load cell , weight sensor |

| Price: |

US $72

/ pc

|

| Min. Order: | 10 pc |

Product Description

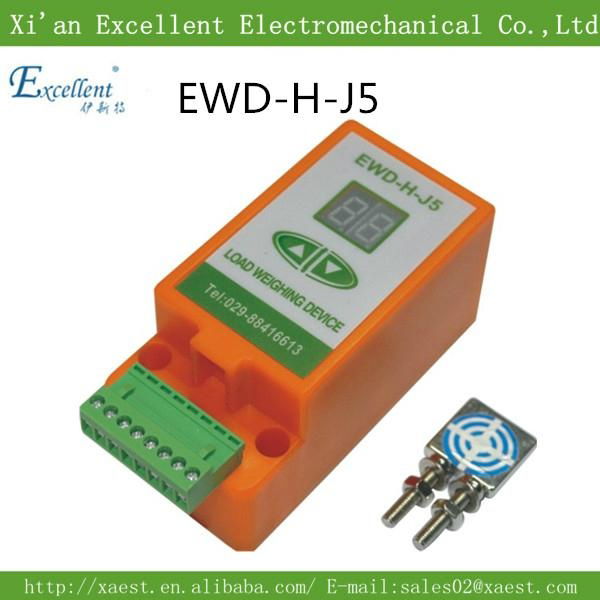

EWD-H-J5 Elevator parts load weighting device /load cell

Type EWD-H-J5 Elevator Load Weighing Device

INTRODTION MANUAL

This system is applicable to all elevators with movable platform car (containing 3-channel programmable switch signals)

Main characters:

1. Contactless inductive working mode, solid state relay output, no need to fix the original position of elevator overload switch, and to change structure of elevator platform car.

- 2.Electrical properties is in compliance with the standard of the International Electro-technical Commission.

- 3.Set up all parameters on the spot.

- 4.Adopt strong inductive magnet, improve the anti-interference ability to the utmost.

- 5.System carry scientifical computing out according to mathematical equations to automatically amend detention of error. It also has no-load auto zero capacity

- 6.It is totally convenient to adjust on the pot by means of artificial self-study or artificial displacement.

- 7.Control method of programmable output signal created by ourself is applicable to all kinds of traction elevator with movable platform car.

- 8.Integrated structure design: small size, easy installation.

|

1 |

Scope of application |

Applicable to all elevators with movable platform car. range of auto-detention (2.0mm ≤car bottom displacement≤10.00mm ); range of manual set displacement: 2.5~9.9mm ( relate to parameter PD) |

|||

|

2 |

sensitivity |

Rated load /200 (5.0kg when rated load is 1 ton) |

|||

|

3 |

System error |

≤1.5% ( 5~40℃ ) |

Working temperature range≤3.0% |

||

|

4 |

nonlinearity |

≤1.0% |

|||

|

5 |

Output form |

Solid state relay |

Programmable universal signal |

① 5 channel programmable output mode are following: no- load, light- load, semi-load, heavy load, rated load and overload (user can freely set up the range of change. ② Each channel can be programmed as dynamic close or dynamic break contact. ③ Coding contact capacity: DC/AC 32V/15mA |

|

|

Elevator load "no load~rated load", analog quantity:0~10Vlinearly changing |

|||||

|

6 |

Storage environment |

-25~75℃ |

|||

|

7 |

Working environment |

Temperature:-20~55℃ |

|||

|

8 |

Relative humidity |

20%~99%RH |

|||

|

9 |

Reaction time |

≤0.25s |

|||

|

10 |

Power supply |

AC/DC24(10%)V/150mA |

|||

|

11 |

Installation position |

movable platform car of elevator |

|||

|

12 |

Machine dimension |

45X45X90㎜3 |

|||

- Working principle

Referring to diagram, by means of Holzer sensor this system tests displacement changing based on platform car of elevator and load elastic variation principle. It use single chip microcomputer to scientifically compute to correct error in terms of given parameter and measuring results based on mathematic equations, which accomplish effective load weighing of the elevator platform car.

|

|

EWD-H-J5 |

Other weighing devices |

|

Working principle |

Adopting Holzer sensor. Accomplishing contactless inductive working. Advantages: ① Has long working life in that this system don't bear load of elevator. ② Width induction & high positioning precision. ③ No system damage arising from insufficient overload capacity and mechanical vibration. ④ Micro sensor & microcomputer make system highly intelligent and lower power waste. ⑤ Automatically amending detection error by means of digital. Good linearity. |

Directly bear elevator load by the way of pressure sensor. |

|

Installing method |

Only need to fasten the device in the middle of bottom of platform car or original position of mechanical switch in the condition of failure to change structure of platform car. Small size & Easy installation. |

Need to change structure of the platform car. Uneasy to install & more work. |

|

Adjusting on the pot |

① Thanks to the high intelligence personnel may complete adjustment of elevator weighing device on the spot after separately press the button of sensor two times following the completion of installation system sensor when elevator is no load or rated load. ② Elevator producer may directly complete quick adjustment of similar elevator by the way of setting-up the manual displacement. Advantages: easy & quick to adjust |

Complicated adjustment owing to the analog signal. |

|

Connecting the interface of output signal on the select layer device |

5-channel programmable output terminal could be set up by user themselves. Selection: no load, light load, semi-load, heavy load, rated load, overload; 0~10V analog output. It is convenient for user to finalize the items below: 1 vandal resistant function. 2 full bypass function. 3 energy saving function. 4 deb ing system torque compensation. |

Single function |

|

Economic analysis |

① High-performance to price ratio, easy to use, low breakdown. ② Less accessories, low additional cost & simple processing |

Average High additional cost |

| Payment Terms: | TT,Paypal,Western Union |

|---|---|

Member Information

| Xi'an Excellent Electromechnical Co.,Ltd | |

|---|---|

| Country/Region: | Shaan Xi - China |

| Business Nature: | Manufacturer |

| Phone: | 15710486683 |

| Contact: | Cherry (Manager) |

| Last Online: | 15 Jul, 2015 |