| Model: | xiermould01001 |

|---|---|

| Brand: | xiermould |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

| Label: | Plastic moulds , auto parts , car accessories |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Mould Parameters:

Place of Origin: Zhejiang, China (Mainland)

Brand Name: XIER MOULD

Mould type: Plastic Injection Mould

Mold base: LKM, standard mould base

Mold material: H13 or other you want

Mold Cavity: Single or Multy cavity

Standard Components: JINHONG, HASCO, DME, MISUMI, PUNCH

Part material: PP, ABS, PC, PA, PE, POM, PPS, TPE, PVC and so on

Feeding System: Cold runner, hot runner such as YUDO, DME, SYVENTIVE, HASCO, INCOE.

Packaging & Delivery

Packaging Details: Rust-proof protection, preservative film, wooden case and pallet(free of fumigation), suitable for shipment, avoid damage.

Delivery Detail: within 7 days of samples & moulds confirmation

Scope of business:

Plastic injection mould (Cold/Hot runner, Insert molding, Over molding, Stack molds), plastic parts producing, gas-assistant molds, bottle blowing mould, ABS rapid prototype by CNC machining

Our Plastic mould used for:

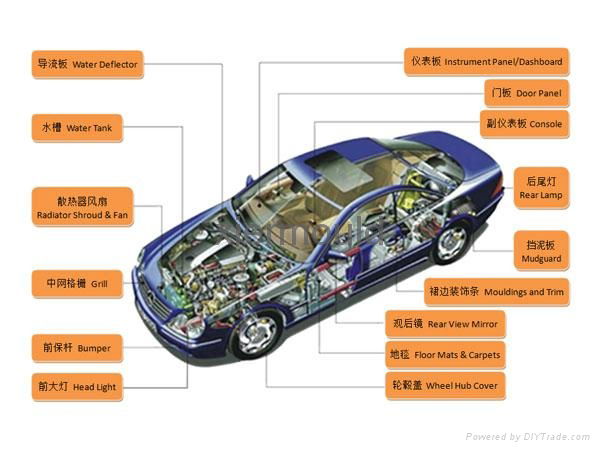

Automotive Exterior & interior decoration accessories, bumper, grill, dashboard, glove box, door pannel, console, lamps & lights, seat trim cover, arm rest, fender & mudguard, radiator shroud, wheel cover, trims, mouldings, spoiler, A B C pillars, water tank, etc.

Home electrical appliances, printers, air conditioners, PC computers, TV, monitors, vacuum cleaners, washing machines, etc.

Toy, baby walker, baby toilet stool, kid scooter, trucks, Self Balancing Electric Scooter

Production process:

1. Gather technical data (Check 2D/3D Part drawings, and Understand the specific requirements of customers);

2. Mould design and internal review;

3. Purchsing material and commponents when we receive design confirmation from customers;

4. Manufacturing (Machining programm and Assembly);

5. Testing mould and delivering samples;

6. Arranging Packing & delivery when received delivery notice from customers.

Interacting with customer:

1. Part analysis and feedback to customer;

2. Production plan and Weekly report;

3. Mould trail and samples checking;

4. One hour mould trail at mass production condition before delivery.

XIER MOULD ensure mould quality:

1. Good mould steel with proper hardness;

2. High quality accessories and good finishings;

3. Precision machining with high precise;

4. Reliable mould structure and long mould life.

XIER MOULD ensure timely, completely and accurately providing services as following:

1. Quoting, mould designing, feedbacking, communicating of technical points;

2. Weekly reporting of mould condition, such as machining progress, schedule or plans;

3. Mould test and sample delivery, and mould delivery on time.

Any mould project, pls do not hesitate to contact us.

| Payment Terms: | TT/Western Union/Cash |

|---|---|

Member Information

| Taizhou Xiermould Co., Ltd. | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 15325557207 |

| Contact: | George (Vice GM) |

| Last Online: | 14 Jul, 2015 |