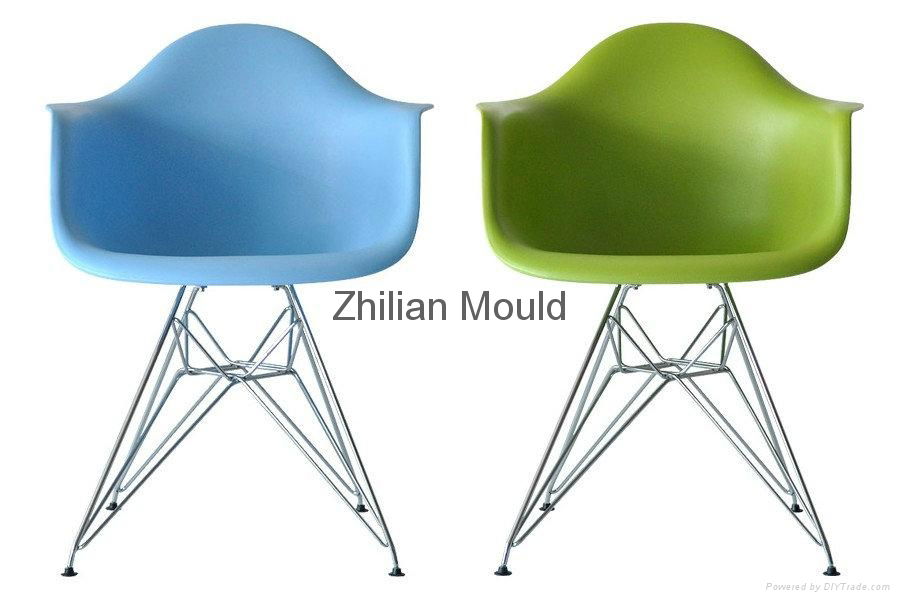

| Model: | chair mould |

|---|---|

| Brand: | Zhilian Mould |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Mold |

| Label: | plastic chair mould , chair mould , chair mould maker |

| Price: |

US $3000

/ set

|

| Min. Order: | 1 set |

Product Description

zhilian mould make palstic kids chair mould,plastic adult chair mould,plastic modern chair mould

1. Quick Details:

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Zhilian Mould

Model Number: ZL623

Shaping Mode: Plastic Injection Mould

Plastic material: PP, PC, PS, PE, PU, PVC, ABS, PMMA ect.

Mould Material: 2738, 2316, H13, 718, S136, SKD61, P20 ect.

Injection Mould running: Full automaticity

CNC Machining Tolerance: 0.003to 0.005mm

Cavity: Single/multi

Gate: Open gates or valve gates

Runner system: Hot runner system made by YUDO or made by ZHILIAN MOULD Manufacturing machine: High-speed CNC, EDM, Wire-line cutting, deep hole drilling machines

Mould life: 550000-1000000shots

2. Specification:

1. Advanced technology

2. Professional design

3. Excellent quality

4. Competitive price

5. Considerate service

6. On time delivery

3. There are three levels of mold quality for your option:

Option A: Level A quality(Highest Level Quality)

Mould Base: DEM, HASCO, LKM

Core/Cavity: S136, SKD61,NAK80,H13

Slider/Insert: S136

Mould spare parts: DME, HASCO

Hot Runner: MASTERS, D-E-M INCOE, HASCO

Mould Life:1,000,000 shots

Cycle Time:20s

Option B: Level B quality(Middle Level Quality)

Mould Base: self-made

Core/Cavity: 718H

Slider/Insert: 718H, 2738

Mould spare parts: Jinhong, China

Hot Runner: YUDO

Mould Life:800,000 shots

Cycle Time:22s

Option C: Level C quality(Lowest Level Quality)

Mould Base: self-made

Core/Cavity: P20

Slider/Insert: P20

Mould spare parts: Jinhong,China

Hot Runner: Zhilian, China

Mould Life:500,000 shots

Cycle Time:23s

Attention pls:

Price varies in different quality levels. When you send us the mould inquiry, please try to offer us the following information:

1)Quality level you choose: Level A/Level B/Level C;

2)Product Photo;

3)Product Dimension;

4)Your special requirements.

Lead time:

It is 50 days for first mould testing after mold design is confirmed.

4. Plastic chair mould quality control

For the Q/C of mold, there are 3 steps:

1.Mold Material Q/C

- Mold Steel Checking(Hardness, flaw detection)

- Mold Standard Spare Parts Checking(hardness, size, flaw checking)

2.Mold Making Process Q/C

- design checking (part design, mold design, mold engineering drawing)

- Each part of mold’s size checking after machining according to 2D drawing

- mold testing(check mold running condition)

3.check with customer’s requirement again before mold shipping.

5. Plastic chair mould packing and shipping

Anti-rust oil is painted first, then Plastic film, and finally Wooden Case.

Sent together with the mold:

a) Mold manual instruction

b) engineering drawing in

c)one more set of mold spare parts:heater,ejector pin,bush,water nozzle,water pipe,hanging ring

6.Plastic chair mould maintenance

a)When the mold is vacant, spray the anti-rust oil

b)To clean the gate and cooling system regularly

c)Avoid to use recycled material if the mold is suitable for virgin material only

7. Our Service

Pre-sale:

Analysing the customer's need with great care

Select the suitable model of machine

Providing perfect solution with accurate machine specification

Sales:

Zhilian Mould will send to buyer the mould schedule and processing report each 10 days.

Zhilian Mould will send the tryout samples for buyer checking and work out improvements requirement.

After-sale:

One year of warranty.

Offering the according parts for free, if any error(not man-made) happens within the period of guarantee.

Offer overseas service if we(the Two Parties) can come to an overseas service agreement.

8. Letter from Alice:

Dear My friend,

This is Alice from Zhilian Mould, we are specialized in manufacturing all kinds of injection moulds.

Should you have any plastic mould projects,welcome to send us the 2D or 3D files and specification.

We will quote our best terms for you ASAP! And Alice is always ready to offering you best service !

If you are interested in plastic chair mould made by Zhilian Mould, please contact with me at any time. I am sure we will provide the best solution for you.

Best regards,

Alice

Add.: No.36 Jinchuan Road, Xinqian Street, Huangyan, Taizhou, Zhejiang,China

Zip code: 318020

Fax: 0086-0576-81116175

Tel: 0086-0576-81116175

Skype: live:18203762051

Whatsapp & We chat:+86 18989672496

Website: http://www.zhilianmould.com

Member Information

| Huangyan Zhilian Mould & Plastic Co., Ltd. | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 18989672496 |

| Contact: | Alice zheng (sales engineer) |

| Last Online: | 18 Apr, 2017 |

Related Products of this Company

-

Taizhou customized plastic paint bucket

US $3000

-

plastic toy mould supplier

US $3000

-

four way plastic pallet mould

US $8000

-

plastic desk mould maker

US $3000

-

plastic injection skateboard mould maker

US $3000

-

plastic helmet mould manufacturer

US $3000

-

Taizhou simple and elegant plastic chair

US $3000

-

plastic stool mould

US $3000

-

Taizhou customized plastic tableware

US $3000

-

Taizhou new design plastic indoor

US $3000